Oil deodorization device, deodorization method thereof and packing stripping pump mechanism

A grease deodorization and steam stripping technology, which is applied in the direction of edible oil/fat, fat oil/fat refining, fat production, etc., can solve the problems of prone to color and aftertaste, unstable oil quality, expensive equipment cost, etc. Effects of deodorization time, reduction of plant construction cost, reduction of deodorization consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a grease deodorization device.

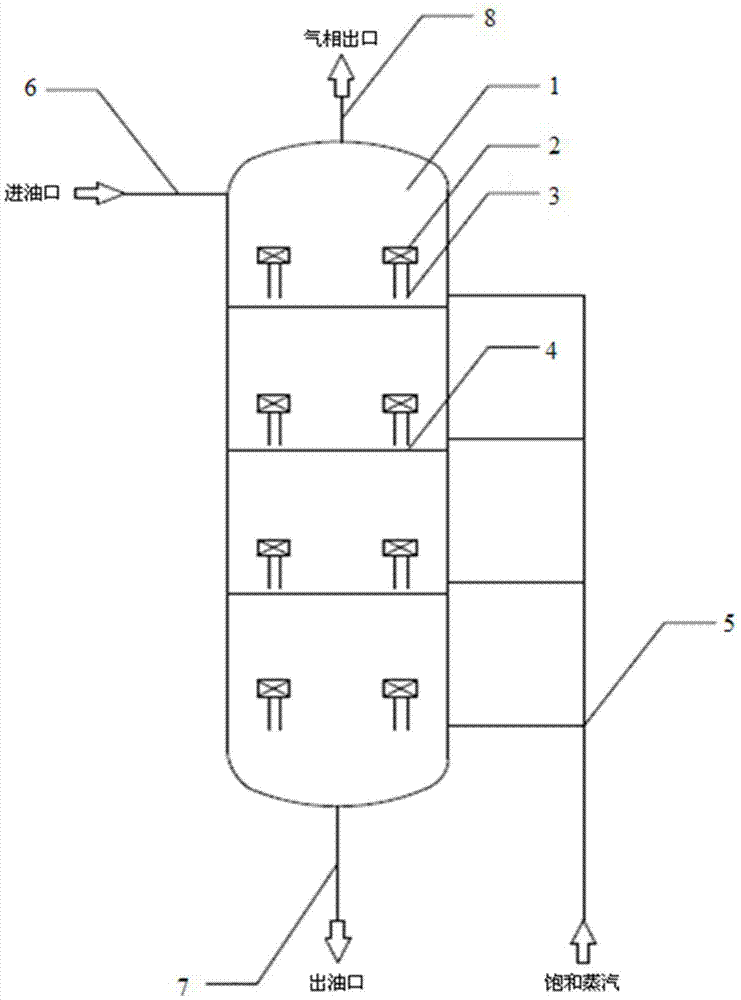

[0049] Such as figure 1 As shown, this embodiment includes: a tower body 1, a multi-layer tray 4 arranged inside the tower body 1, and several packing stripping pump mechanisms arranged on each layer of tray 4, and any packing stripping The pump mechanisms all include a stripping pump 3 and a packing 2 , the stripping pump 3 is arranged on the tray 4 , and the packing 2 is arranged on the top of the stripping pump 3 .

[0050] Further, this embodiment also includes the following structures:

[0051] - The oil inlet pipeline 6, the oil inlet pipeline 6 is connected to the top of the tower body 1, and its oil inlet is arranged on the outside of the tower body 1;

[0052] - the oil outlet pipeline 7, the oil outlet pipeline 7 is connected to the bottom of the tower body 1, and its oil outlet 7 is arranged outside the tower body 1;

[0053] -direct steam pipeline 5, described direct steam pipeline 5 is provided wi...

Embodiment 2

[0069] This embodiment provides a packing stripping pump mechanism used in the grease deodorization device of Embodiment 1.

[0070] This embodiment includes a stripping pump and packing, and the packing is arranged on the top of the stripping pump.

[0071] The filler is arranged in a cavity at the top of the stripping pump, and the cavity is a hollow cube, hollow cuboid, hollow cylinder or hollow trapezoid.

[0072] An opening is provided on the side of the cavity to facilitate gas-liquid separation.

[0073] A through hole is provided below the cavity, and the through hole is directly connected to the outlet provided on the top of the stripping pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com