A control method for decarburization of fine-gauge heat-treated steel wire

A control method and technology of steel wire, applied in the direction of heat treatment process control, heat treatment furnace, heat treatment equipment, etc., can solve the problems of increasing the risk of decarburization, fast heating temperature, and incomplete drying, so as to achieve the detection of decarburization risk reduction, Customer yield improvement, usage and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

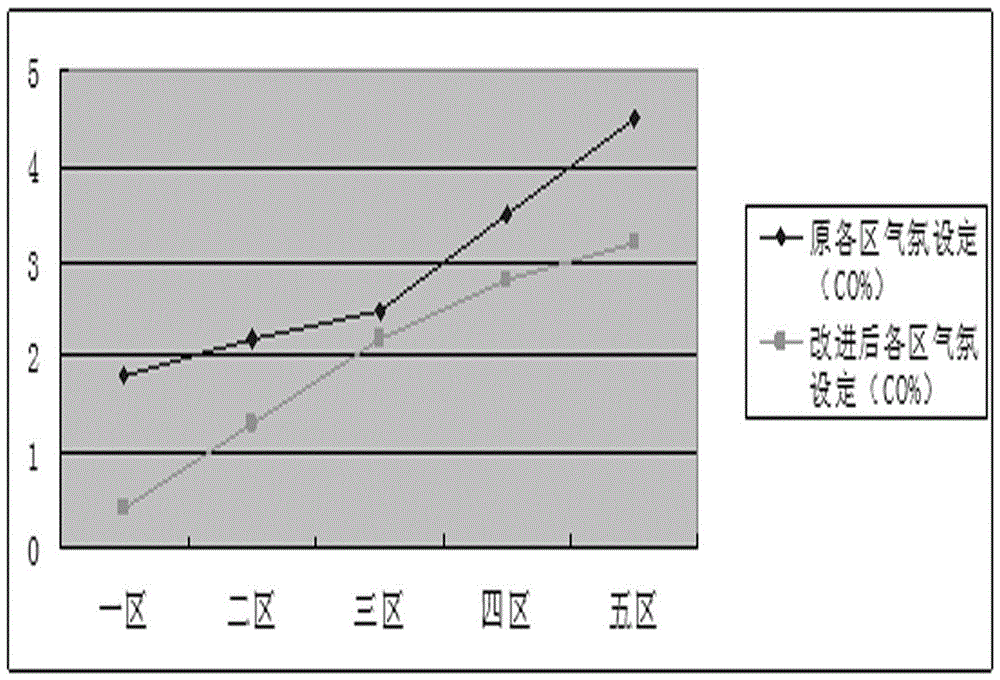

[0015] The present invention is a method for controlling the decarburization of fine-sized heat-treated steel wires, which comprises the following steps: Step 1, adding cleaning balls to remove excessive soap powder on the surface of the steel wires: first, adding soap powder with the same or similar specifications to the steel wires at the wire-releasing place. Wipe the surface of the steel wire with a cleaning ball to reduce the content of soap powder on the surface of the steel wire, avoiding decarburization on the surface of the steel wire caused by excessive heating speed; step 2, the small-sized steel wire must be fully dried before entering the open flame furnace: the steel wire is degreased Before the tank, first use cold air to blow off the water on the surface of the steel wire, and then use the double blowing and drying device to remove the water from the steel wire for the second time, so that the small-size steel wire can be fully dried. The furnace atmosphere of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com