Hydraulic combined oscillating floater wave energy generation device

A power generation device and combined technology, which is applied in ocean energy power generation, engine components, machines/engines, etc., can solve the problems of short wave energy cycle, high energy flow density, and low utilization rate, and achieve high wave energy utilization rate , Improve the energy conversion rate, the effect of less energy conversion times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

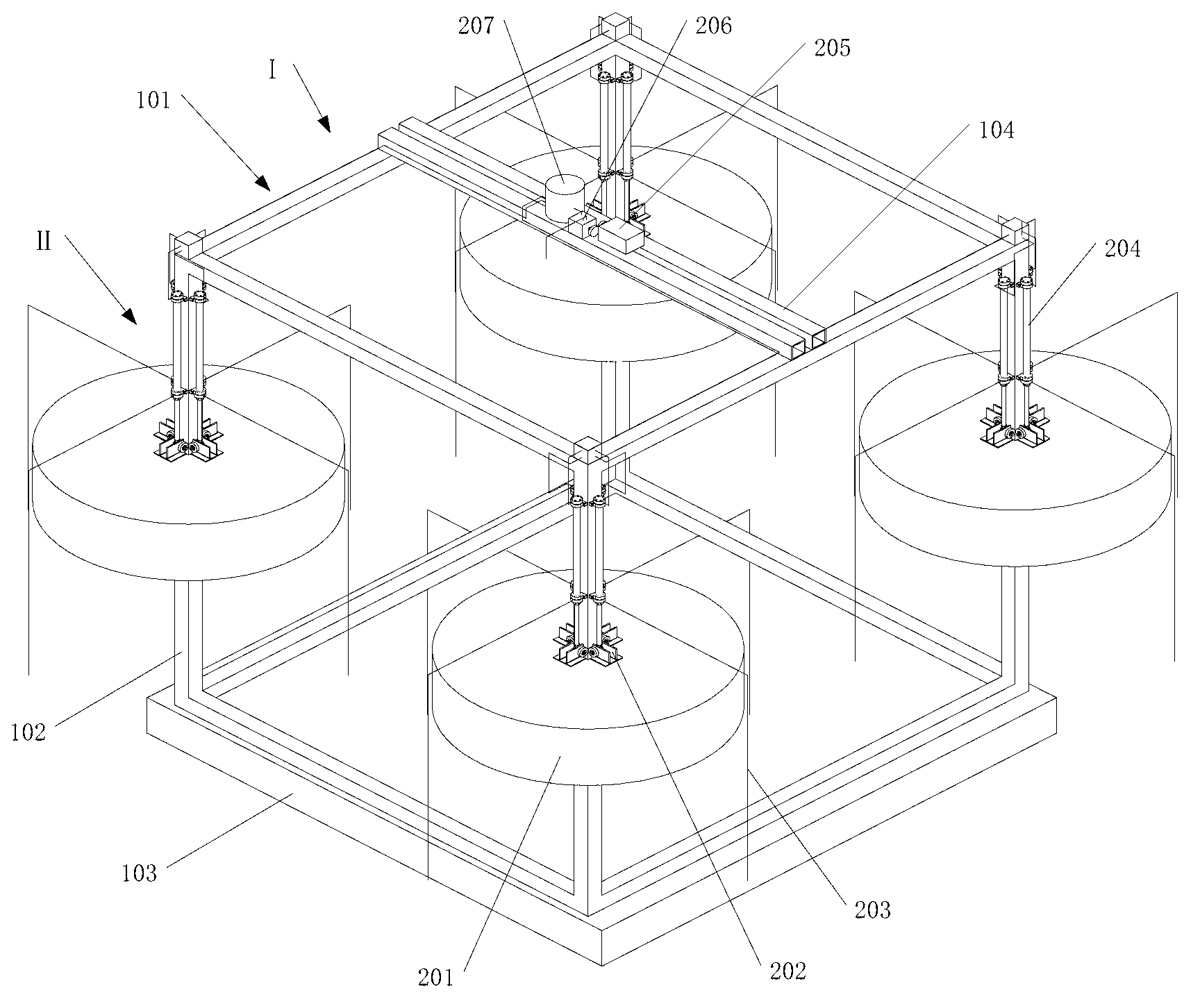

[0028] Such as Figure 1-Figure 4 Shown: the present invention includes power generation system II and fixed system I.

[0029] Among them, the fixed system I includes a floating tank 103 and a fixed frame 101. The fixed frame 101 is a cube structure, which is fixedly connected to the top of the floating tank 103. The top of the fixed frame 101 is provided with a beam 104. The four corners of the fixed frame 101 are respectively provided with columns 102 and 102 For the quadrangular prism structure.

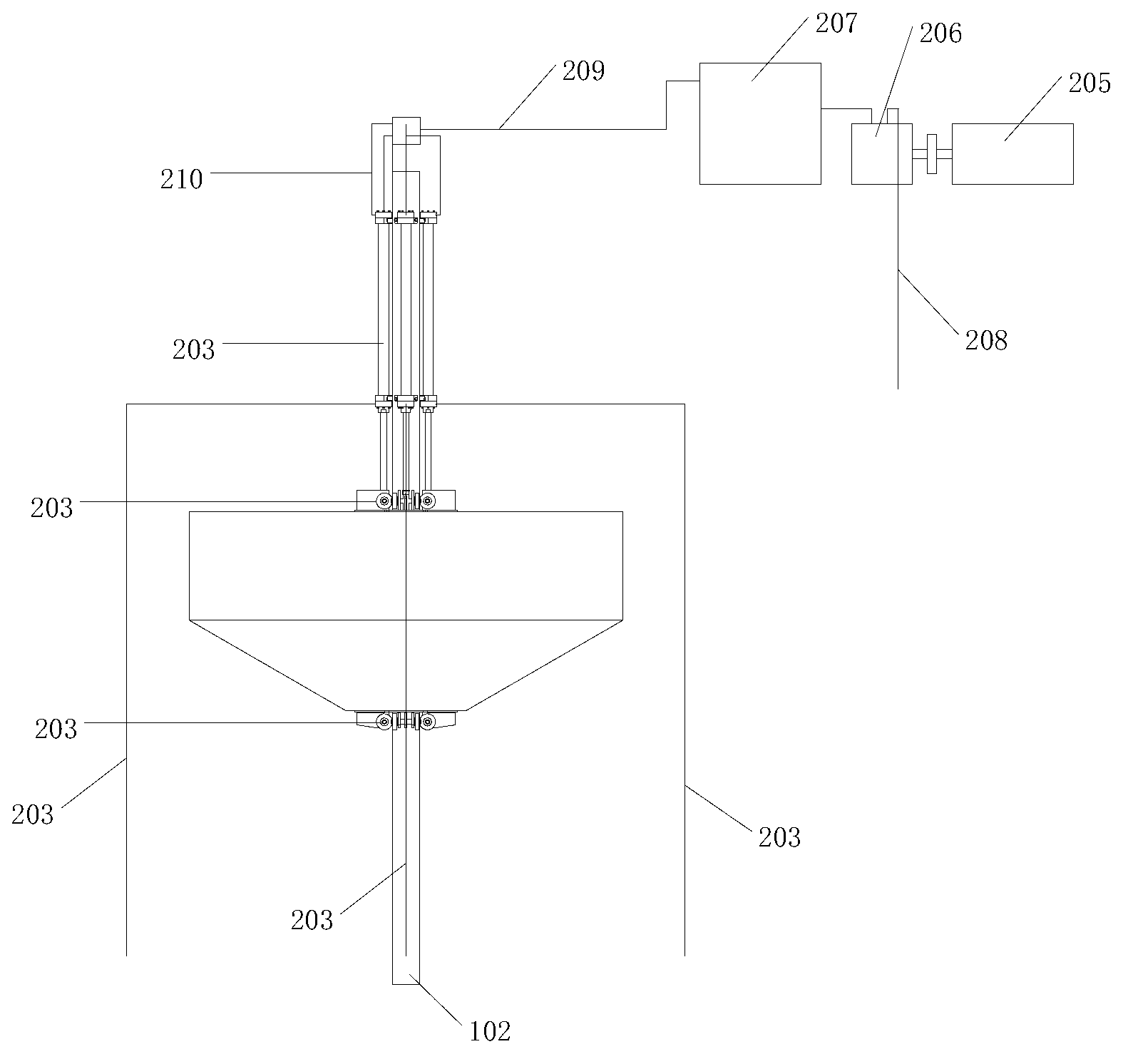

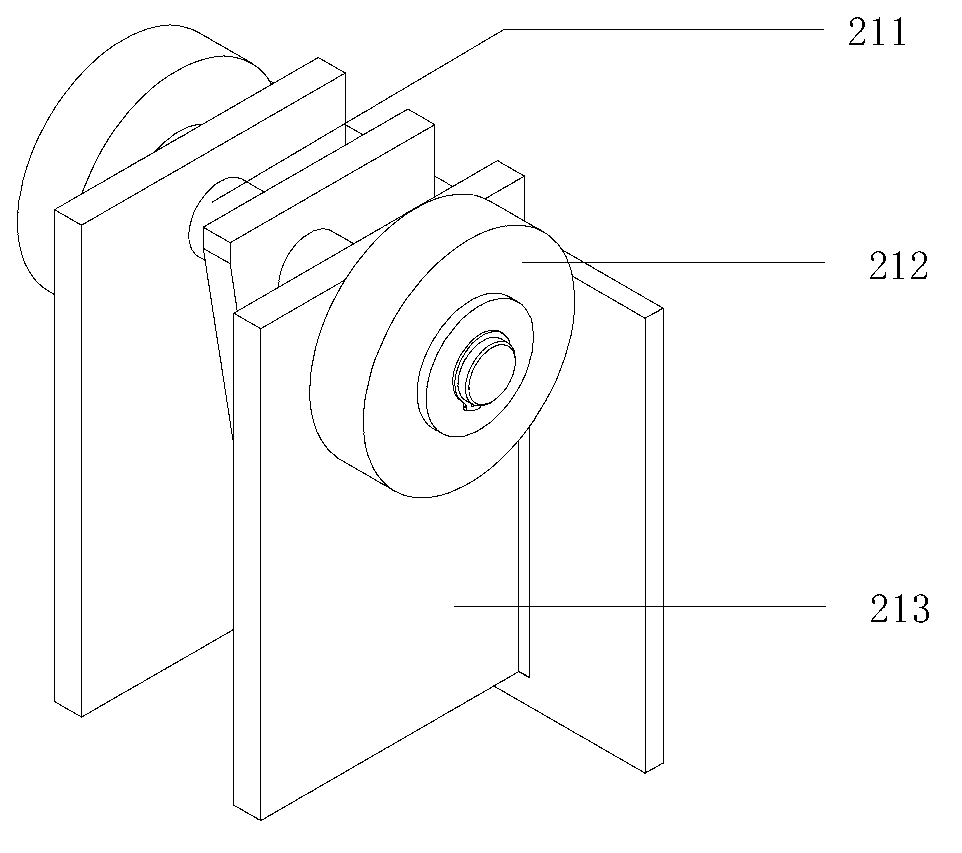

[0030] The power generation system II includes a float 201, an energy conversion device and an energy output device. The four columns 102 are respectively fitted with floats 201 , and the floats 201 move up and down along the columns 102 . The top and bottom of each float 201 are provided with four identical guiding devices 202 for limiting the movement of the float 201 in the horizontal direction. The guiding device 202 can eliminate the influence of waves on the horizontal o...

Embodiment 2

[0036] Except following difference, other is with embodiment 1.

[0037]The buoyancy tank 103 is a hollow structure, which can be filled with appropriate amount of seawater or sand for counterweight according to the sea conditions, so that the entire power generation device can sink to a certain depth below the water surface, and the float 201 can vibrate up and down at a suitable position, while ensuring The stability of the power generation plant as a whole during operation. The fixed system I has a simple structure and flexible counterweight, which improves the stability and reliability of the entire power generation device, facilitates processing and implementation, and is economical.

[0038] The buoy box 103 provides a downward pulling force through its own weight and the counterweight of the sand in the box, so that the entire power generation device can be immersed in a certain depth of the seabed, so that the float 201 makes normal reciprocating vibrations up and down...

Embodiment 3

[0040] Except following difference, other is with embodiment 1.

[0041] Such as Figure 5 As shown, the float 201 is a hollow cylinder with an inverted conical bottom. The structure of the buoy 201 is conducive to collecting more wave energy, and its inner hollow can be loaded with counterweight according to sea conditions. The surface layer of the float 201 is coated with anti-corrosion paint to prevent corrosion by seawater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com