Method for calibrating performance curve of single water pump in urban water plant pump station

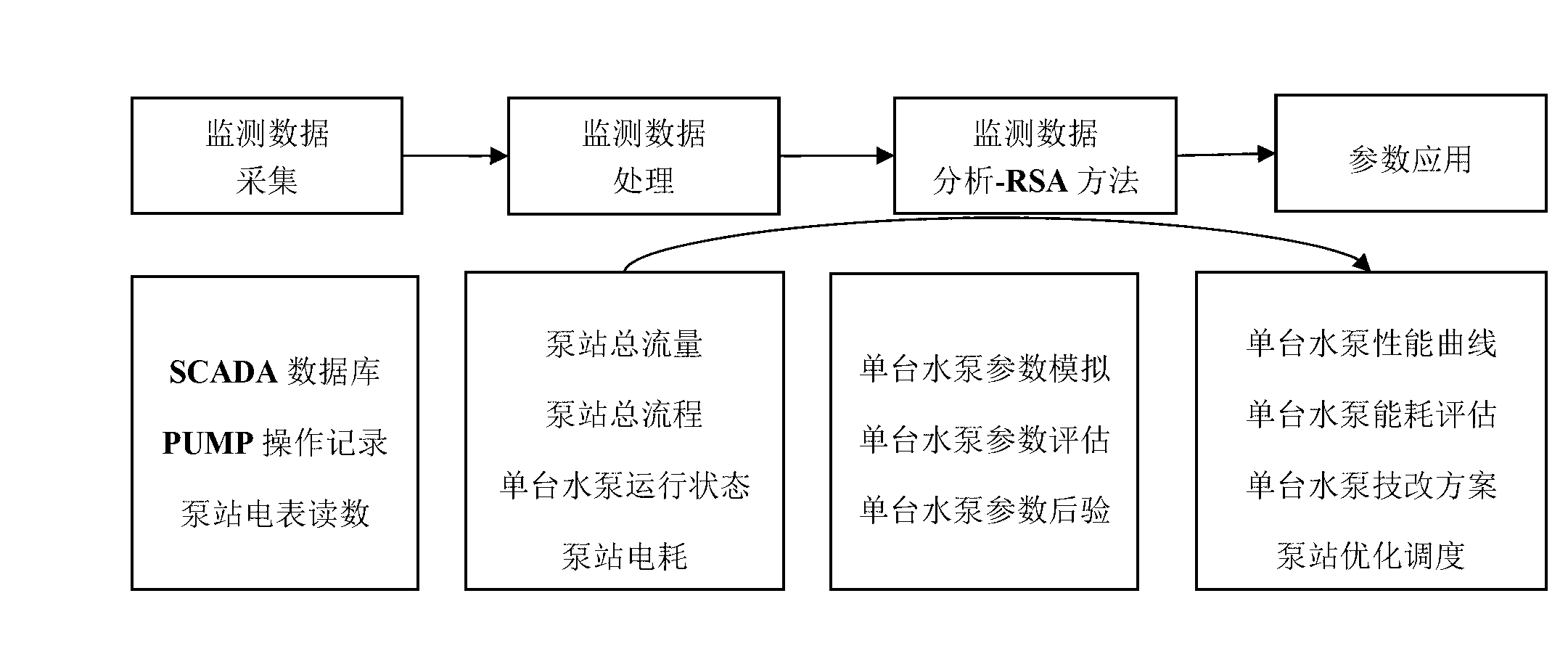

A technology of water pump performance and pumping station, which is applied in the field of parameter estimation of water supply pipe network equipment, can solve the problems that traditional methods are not suitable, there are many factors affecting the measurement accuracy, and it is difficult to guarantee the safety of water supply, so as to avoid experimental measurement calibration and save Field test work, the effect of narrowing the range of values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

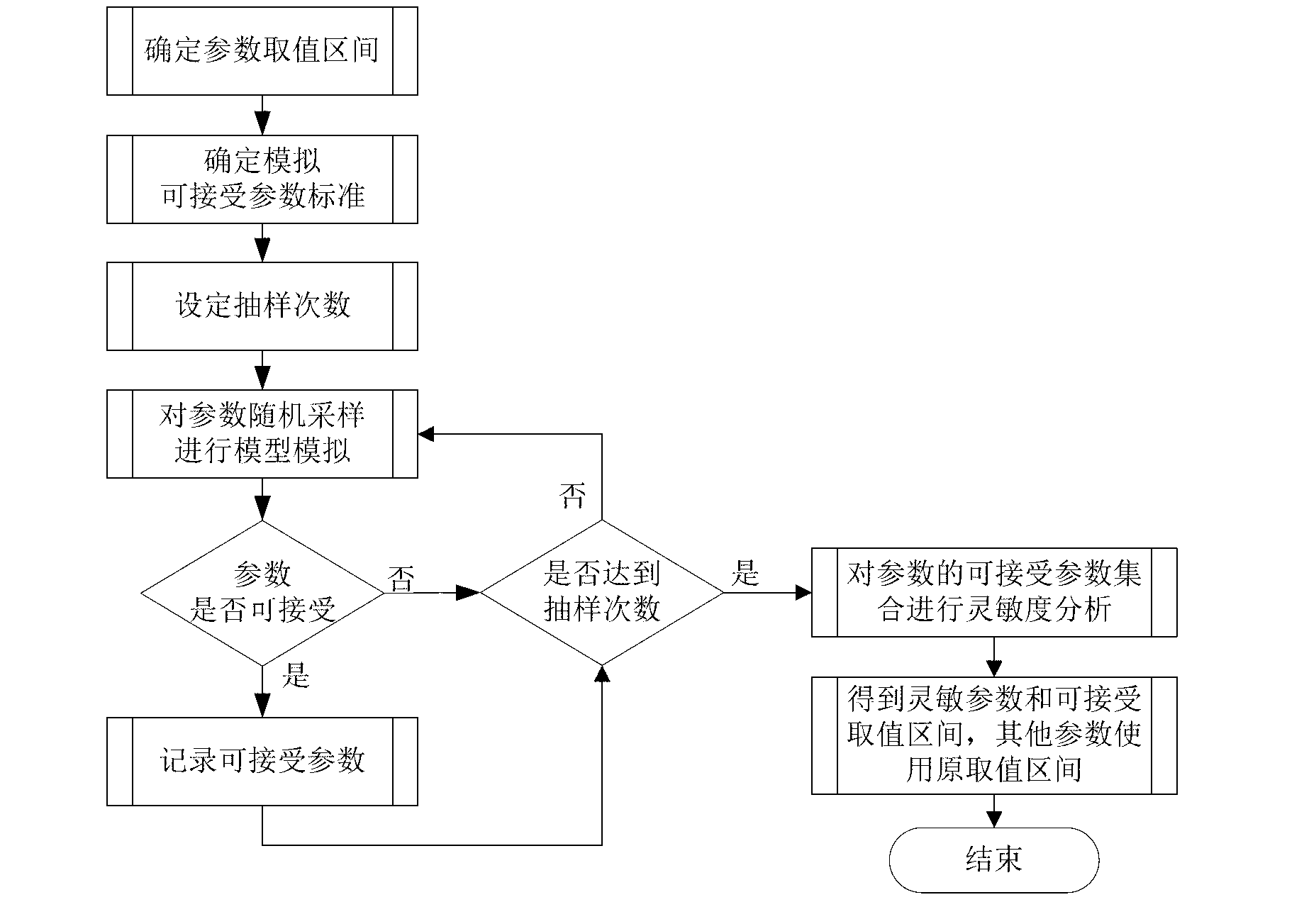

Method used

Image

Examples

Embodiment 1)

[0140]A city’s smart water project applied the method of the present invention to accurately obtain the characteristic curves of 11 water pumps (including 8 power frequency pumps and 3 variable frequency pumps), and identified low-efficiency water pumps through this method and replaced them. .

[0141] The city's water affairs system includes two water plants with a total of 11 pumps that are frequently used. Among them, one water plant has 1 variable frequency pump (XW6), 5 power frequency pumps (XW2, XW4, XW8, XW9, XW10), and the 6 pumps There are a total of 11 combinations of pump operation, that is, the operation of 1 to 5 power frequency pumps, the operation of 1 to 5 power frequency pumps and 1 variable frequency pump, and the operation of only 1 variable frequency pump. There are 11 types in total.

[0142] The combined state of the pump is represented by numbers, the value is 0 when the power frequency pump is off, and the value is 1 when it is on; the value is 0 when...

Embodiment 2)

[0156] The steps of evaluating the flow error and evaluating the head error in the calibration method of the present invention will be introduced below.

[0157] Figure 5 It is a schematic diagram of the basic steps of evaluating flow error and head error in the present invention.

[0158] Depend on Figure 5 It can be seen that the basic steps of evaluating the flow error and evaluating the head error of the present invention are the same, and the difference is that in evaluating the flow error, the designated head of the working condition record is used to calculate the flow error to evaluate the parameters; and in evaluating the head In the error, the head error is calculated by using the specified flow rate recorded by the working condition to evaluate the parameter. Therefore, refer to the following Figure 5 , only the step of evaluating the flow error in the present invention is introduced.

[0159] Such as Figure 5 As shown, the steps of evaluating the flow erro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com