Hydraulic control system for reverse locks and operating method thereof

A technology of hydraulic control system and working cylinder, which is applied in the direction of transmission control, components with teeth, belt/chain/gear, etc., which can solve the problems of increasing driver fatigue and inability to guarantee safety, and achieve light and labor-saving operation , small friction resistance, combined with soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

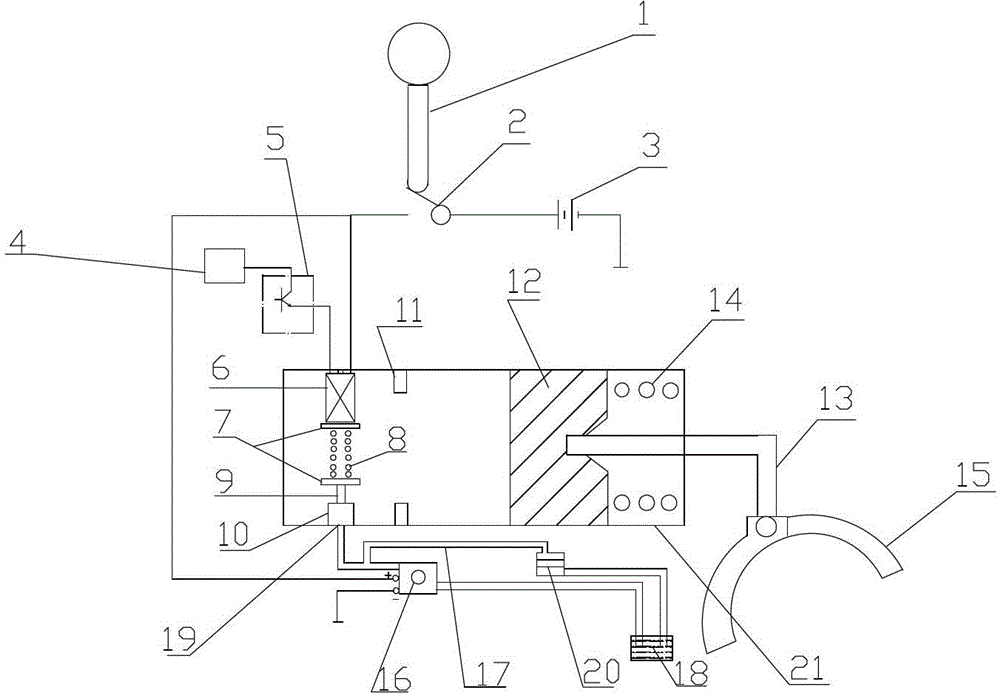

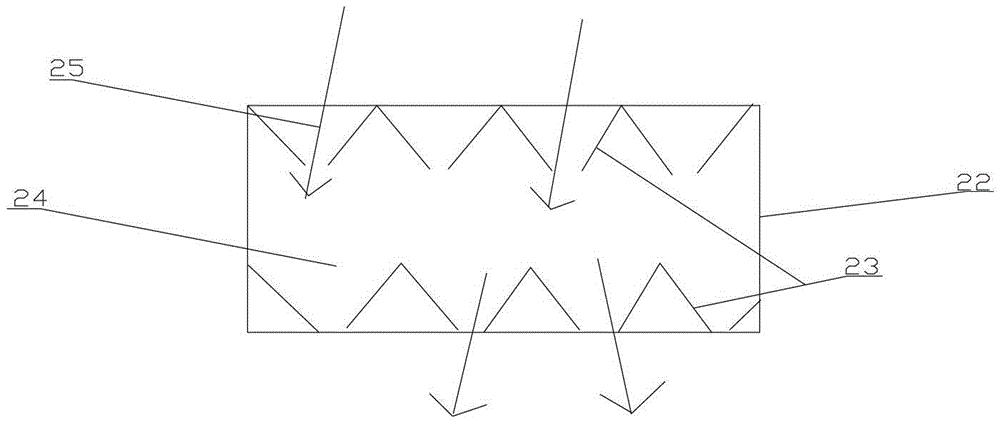

[0027] 1—shift handle; 2—normally open contact; 3—power supply; 4—vehicle speed sensor; 5—electric control component; 6—electromagnetic coil; 7—spring seat; 8—compression spring; 9—armature; 10— Check valve; 11—retaining ring; 12—piston; 13—push rod; 14—return spring; 15—reverse shift fork; 16—electric motor oil pump; 17—oil pipe; 18—liquid storage chamber; 19—oil inlet 20—oil pressure regulator; 21—working cylinder; 22—one-way valve body; 23—one-way plate; 24—one-way valve inner cavity; 25—hydraulic oil flow direction.

[0028] The present invention will be further described below with reference to the accompanying drawings.

[0029] Such as figure 1 As shown, the hydraulic control system of the reverse gear lock in the embodiment includes a shift handle 1, a normally open contact 2, a power supply 3, a vehicle speed sensor 4, an electric control assembly 5, an electromagnetic coil 6, a spring seat 7, and a compression spring 8 , armature 9, one-way valve 10, retaining ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com