Pulse tube/Stirling gas coupling composite multi-stage refrigerator

A pulse-tube refrigerator and pulse-tube refrigeration technology, applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems that the length gap sealing of the ejector cannot be guaranteed, and the refrigeration temperature lower than 10K cannot be efficiently obtained, and the whole process can be achieved. The effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

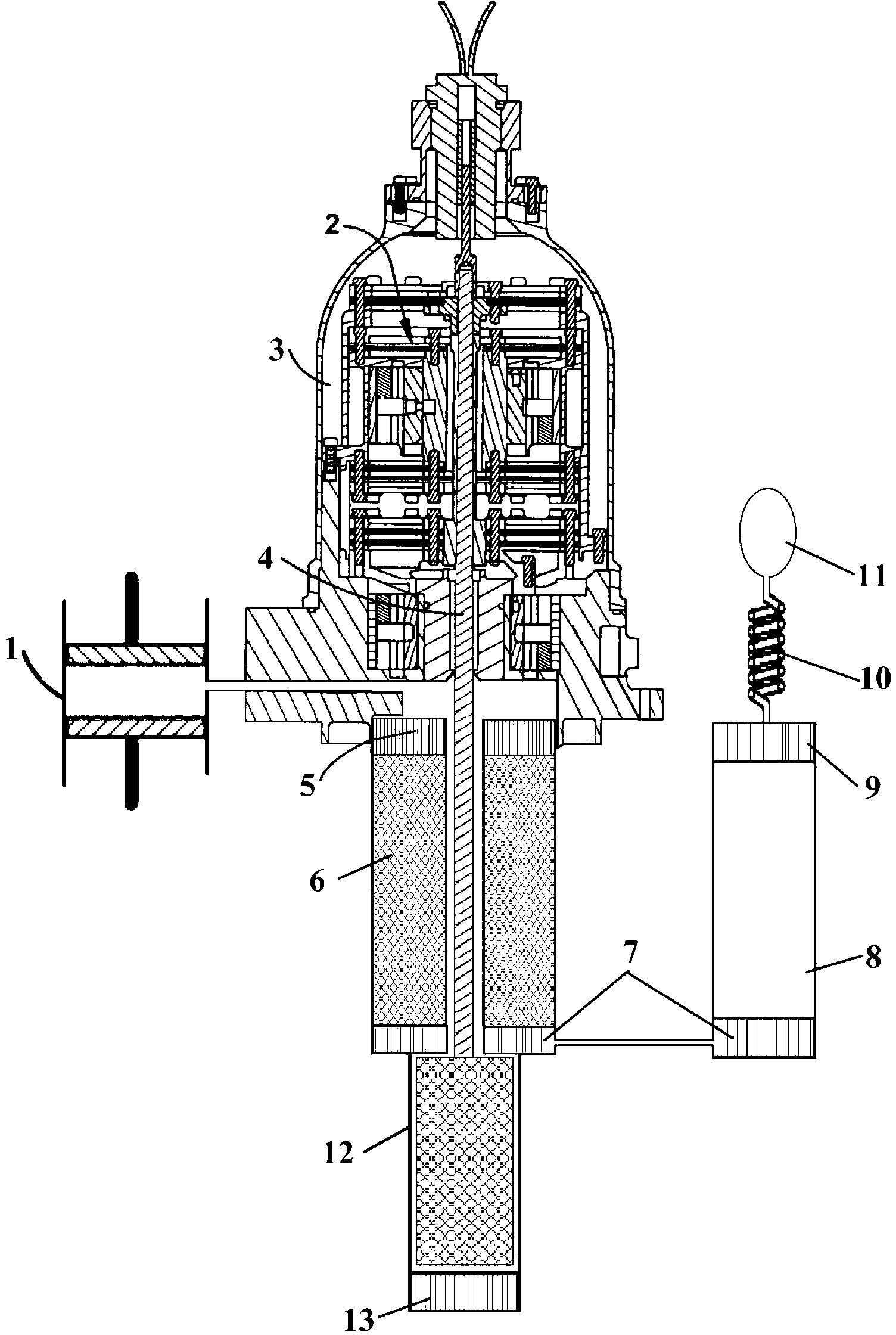

Embodiment 1

[0021] like figure 1 As shown, a two-stage pulse tube / Stirling gas-coupled composite multi-stage refrigerator includes: a linear compressor 1, an ejector drive motor 2, an expansion unit 3, an ejector 4, a hot end heat exchanger 5, a second First stage pulse tube refrigerator regenerator 6, first stage cold end heat exchanger 7, first stage pulse tube 8, first stage pulse tube hot end heat exchanger 9, first stage inertial tube 10, first stage Gas storage 11, second stage Stirling refrigerator cylinder 12, second stage cold end heat exchanger 13.

[0022] The connection relationship of the above-mentioned components is as follows: the linear compressor 1 is connected to the expansion unit 3 and the hot-end heat exchanger 5 respectively, and the ejector driving motor 2 is arranged in the expansion unit 3 and connected to the ejector 4 for driving the ejector 4 In operation, the hot end heat exchanger 5 and the first-stage pulse tube refrigerator regenerator 6, the first-stage ...

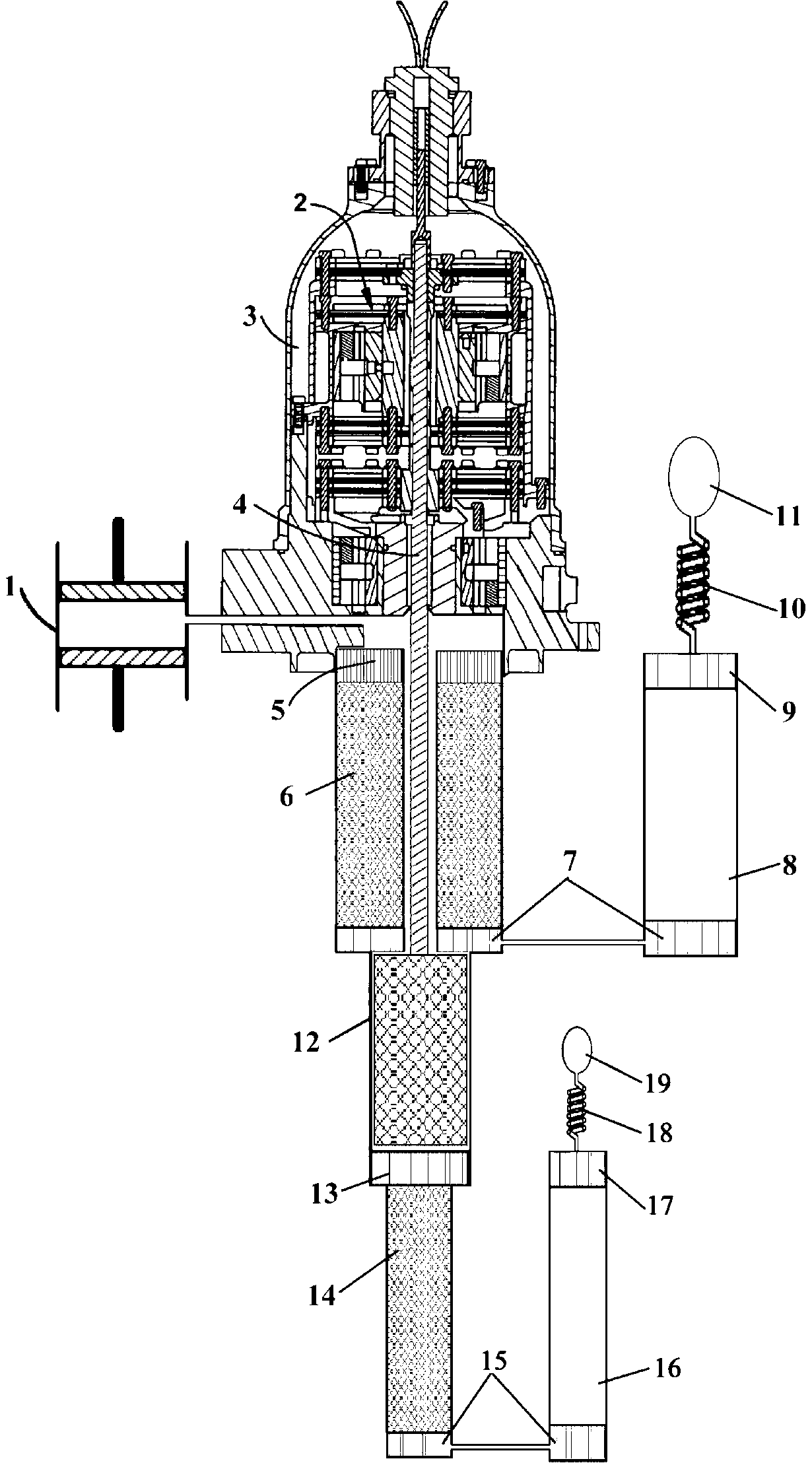

Embodiment 2

[0027] like figure 2 As shown, a three-stage pulse tube / Stirling gas-coupled composite refrigerator differs from Embodiment 1 in that a third-stage pulse tube is sequentially connected after the second-stage cold end heat exchanger 13 of Embodiment 1. Tube refrigerator regenerator 14, third-stage cold-end heat exchanger 15, third-stage pulse tube 16, third-stage pulse tube hot-end heat exchanger 17, third-stage inertial tube 18, and third-stage gas storage 19 . By adding the third-stage pulse tube refrigerator, a lower refrigeration temperature can be obtained in the third-stage cold-end heat exchanger 15, thereby meeting the application requirements for lower temperatures.

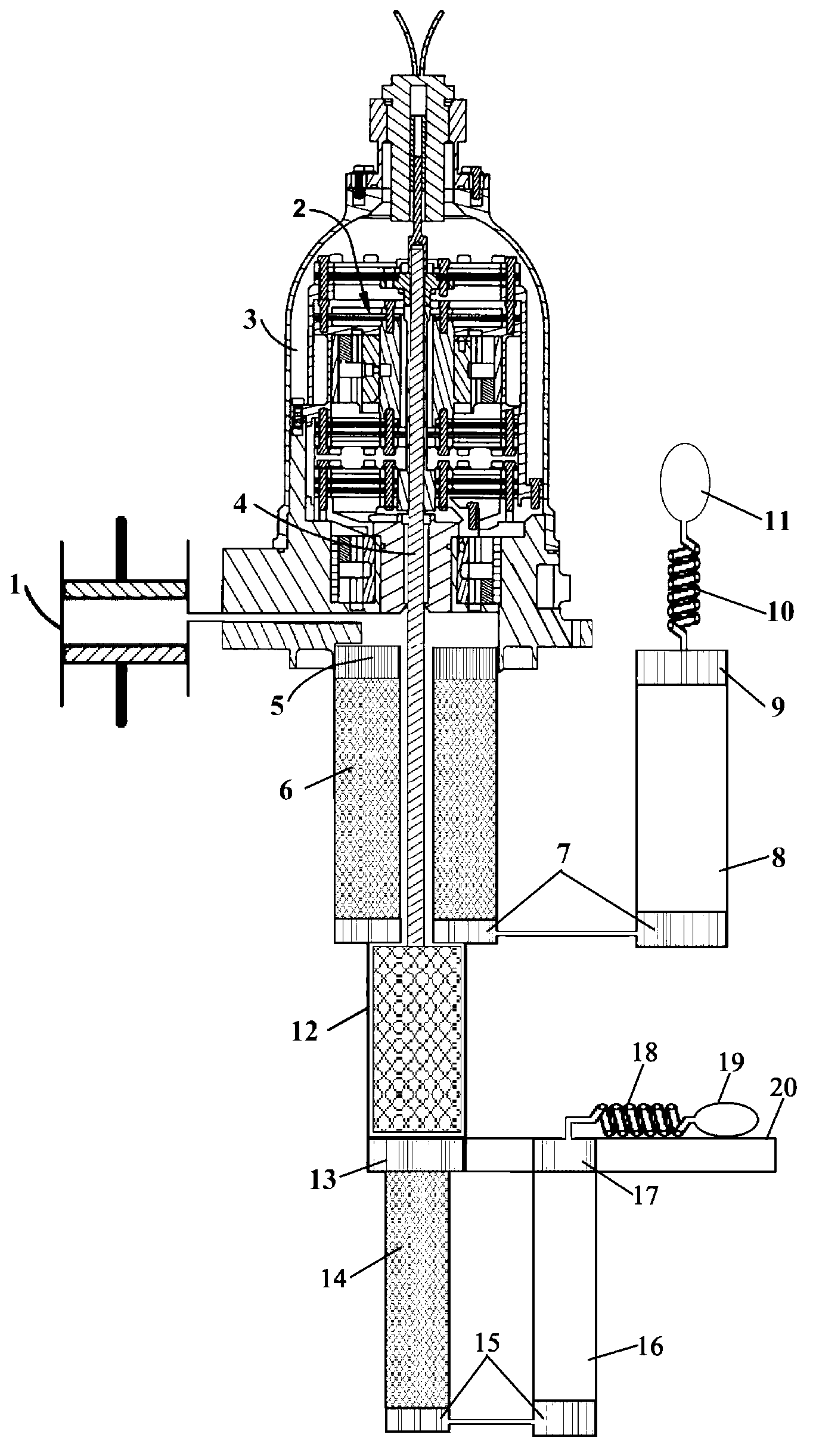

Embodiment 3

[0029] like image 3 As shown, a three-stage pulse tube / Stirling gas-coupled composite refrigerator differs from Embodiment 2 in that the second-stage cold-end heat exchanger 13, the third-stage pulse-tube hot-end heat exchanger 17, the first The third-stage inertia tube 18 and the third-stage gas storage 19 are respectively connected to the thermal bridge 20. By cooling the third-stage inertia tube 18 and the third-stage gas storage 19 to a lower temperature, a larger phase adjustment angle can be obtained. Thus making the pulse tube / Stirling composite refrigerator more efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com