Liquid storage structure of rotary compressor

A technology of a rotary compressor and a liquid storage structure, applied in the field of rotary compressors, can solve the problems of high cost, increased noise, and increased installation volume of the rotary compressor, and achieves reduction of noise and vibration, reduction of suction overheating, and simple structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

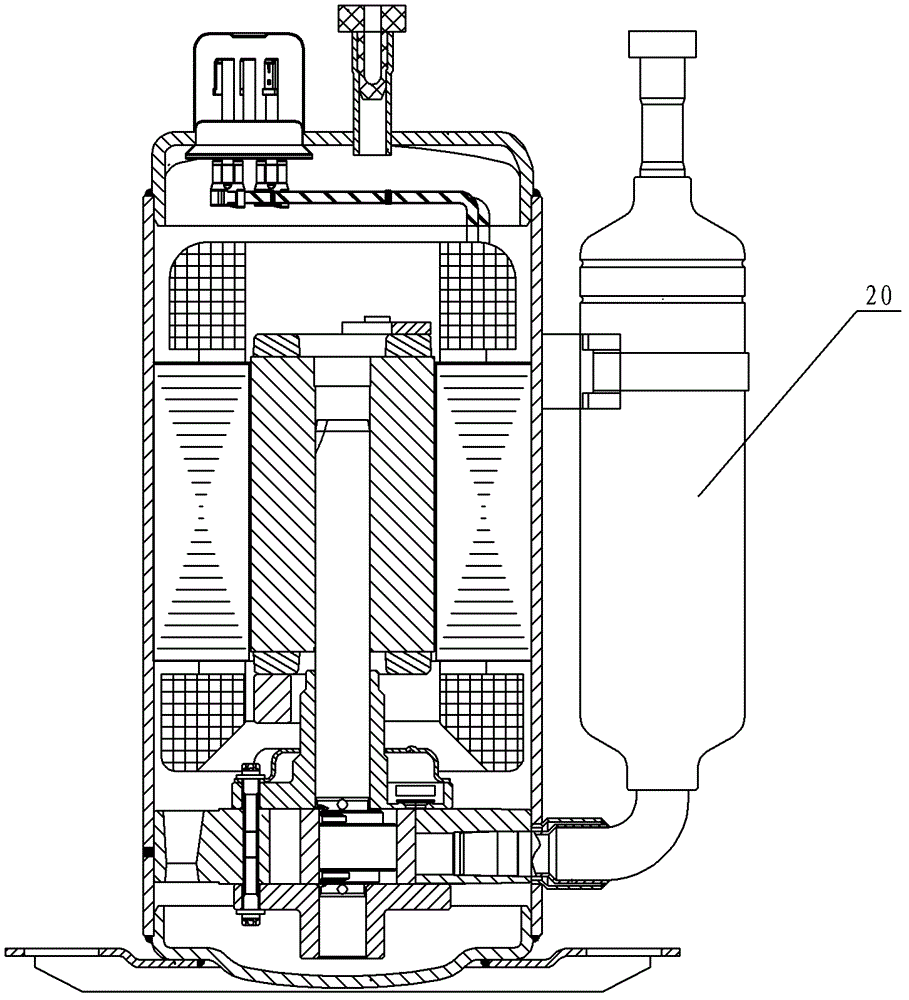

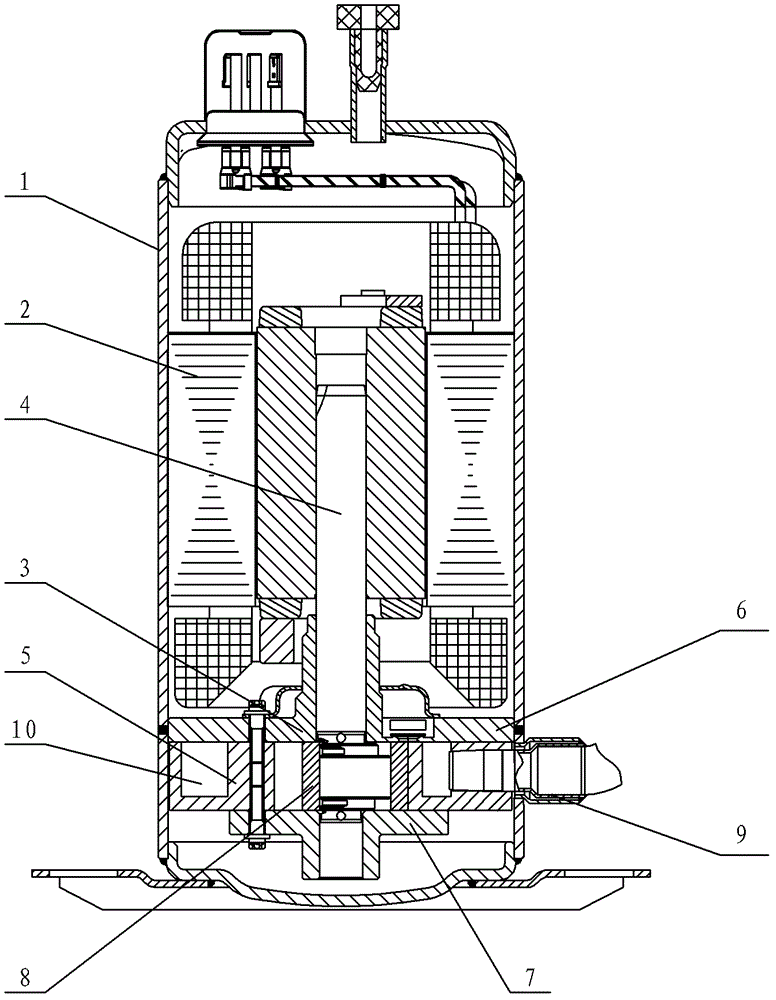

[0026] see Figure 2-Figure 7 , the liquid storage structure of the rotary compressor, the housing 1 of the compressor is provided with a motor 2 and a compression mechanism 3, the motor 2 is connected to the crankshaft 4 in the compression mechanism 3, the compression mechanism 3 includes a cylinder 5, and is housed in the cylinder 5 The piston 8 inside, the crankshaft 4 driven by the eccentric shaft to rotate eccentrically, the main bearing 6 and the auxiliary bearing 7 supporting the crankshaft 4, the main bearing 6 and the auxiliary bearing 7 are arranged on the cylinder 5, and the end face of the piston 8 is in contact with the main bearing 6. The end surfaces of the auxiliary bearing 7 located in the cylinder 5 are in gap contact and slide relative to each other. The cylinder 5 is provided with a slide groove 5.3 and a suction pipe installation hole 5.1 for installing the suction pipe 9 .

[0027] The cylinder 5 is provided with a liquid storage chamber 10, one end of th...

Embodiment 2

[0031] see Figure 8 , in this embodiment, the liquid storage chamber 10 is formed by sealing the through groove provided on the cylinder 5 and the widened flange end faces of the main bearing 6 and the auxiliary bearing 7 together.

[0032] See embodiment 1 for all the other undescribed parts, and will not repeat.

Embodiment 3

[0034] see Figure 9 , in this embodiment, the liquid storage chamber 10 is formed by sealing together the sinking groove provided on the cylinder 5 and the widened flange end surface on the auxiliary bearing 7 .

[0035] See embodiment 1 for all the other undescribed parts, and will not repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com