Biomass wood pellet drying machine

A biomass and dryer technology, applied in the field of dryers, can solve the problems of insufficient water evaporation, uneven drying of materials in rotary drum dryers, etc., and achieve the effect of improving the utilization rate of wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

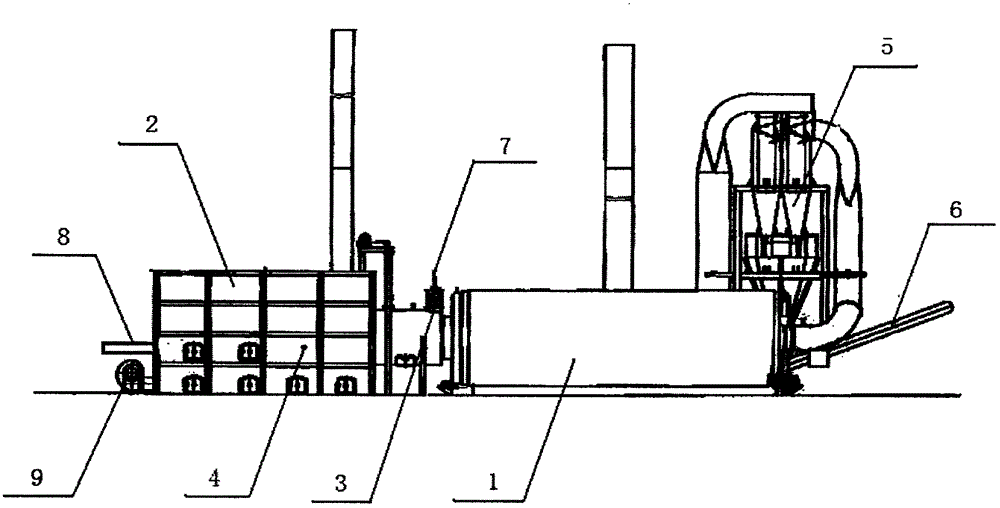

[0015] Such as figure 1 As shown, the biomass sawdust particle dryer of the present invention includes a natural fan, a calciner, a screw conveyor, a host, a dust collector, a temperature sensor, a combustion fan 9 is arranged beside the calciner 2, and the heat output end is connected to the host 1. The input end of the main engine 1 is connected to the screw conveyor 3, and the output end is connected to the belt conveyor 6 and the dust collector 5. Both the main engine 1 and the calciner 2 are equipped with a temperature sensor 4, and the screw conveyor is equipped with a speed controller. The calciner 2 is The wood waste combustion furnace and the calciner are provided with a combustion-supporting broken air duct 8 .

[0016] The aforesaid governor is the main transmission gear 7 of a specific radius installed on the screw conveyor 3 . Calciner 2 is a manual burner for wood waste. The dust collector 5 is a cyclone dust collector. The main drive gear 8 has a radius of 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com