Detection method of austenite stainless steel plastic deformation

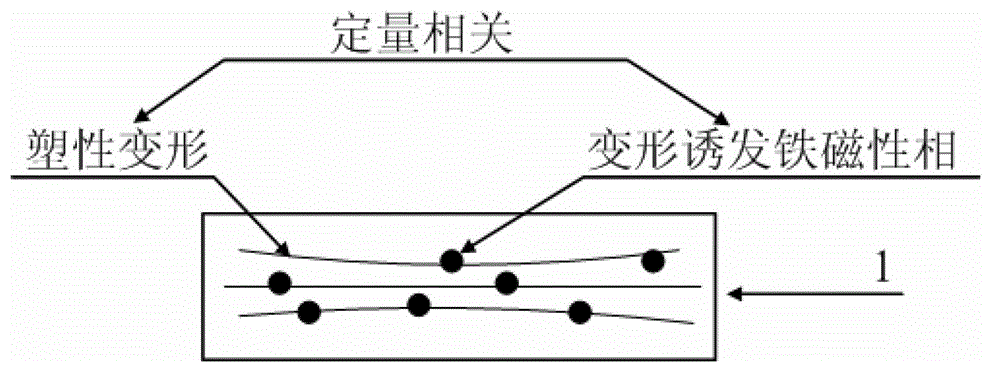

A technology of austenitic stainless steel and plastic deformation, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of low detection efficiency, long detection time, large excitation current, etc., achieve high detection efficiency, no need The effect of surface treatment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step: the plastic deformation of austenitic stainless steel - the establishment method of the calibration curve of the DC magnetization residual magnetic field strength, the specific steps include:

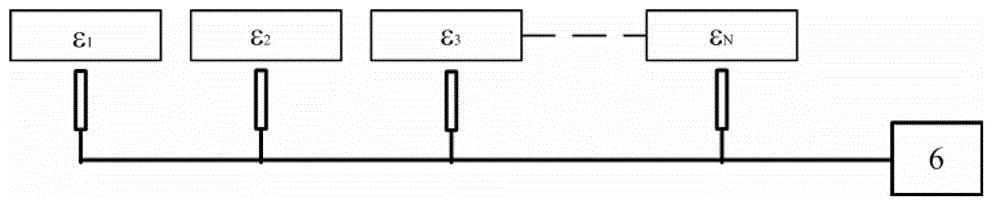

[0028] 1) Refer to figure 2 , making austenitic stainless steel 304 series test pieces, stretching them with a stretching machine, and introducing different degrees of plastic deformationε 1 , ε 2 , ε 3 …ε N , that is, 0.5%, 1%, 2%...30%, and the degree of plastic deformation ε of different specimens is measured by optical strain detection equipment 6 1 , ε 2 , ε 3 …ε N .

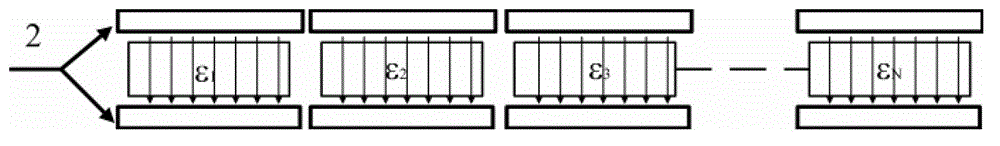

[0029] 2) Refer to image 3 , using a DC magnetization device 2 with a strength of 200mT to conduct DC magnetization perpendicular to the surface of the test object for all test pieces.

[0030] 3) Refer to Figure 4 , using the fluxgate magnetic field measuring device 4 to measure the residual magnetic field intensity B of all test pieces after DC magnetization and perpendicular to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com