Goniometer verification method based on optical lever

A technology of optical levers and photodetectors, applied in instruments, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The verification method of an angle measuring device based on an optical lever comprises the following sequential steps:

[0077] Step 1: Build a verification device in a closed and light-proof room, and install the angle measuring device to be verified, including the following steps:

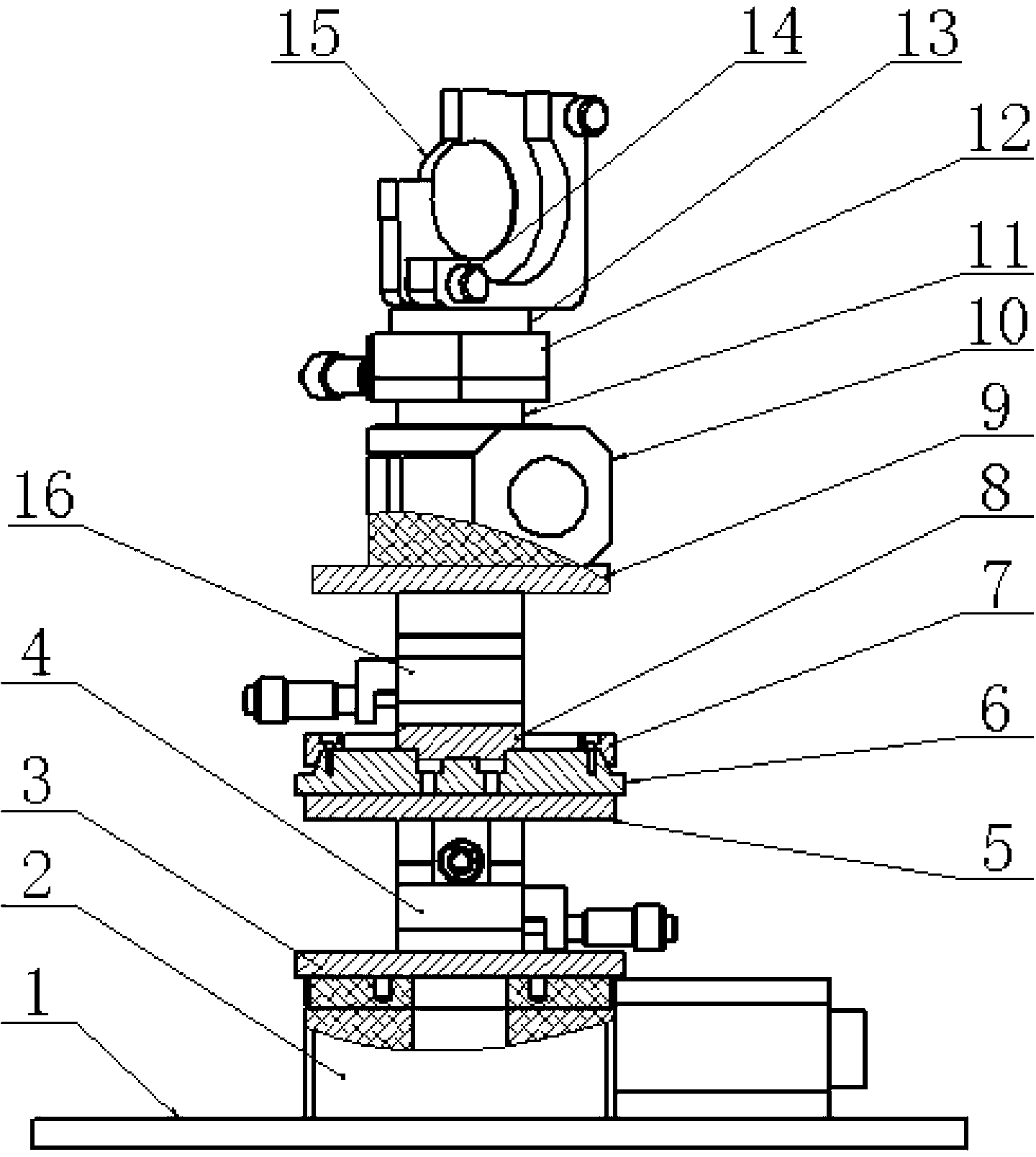

[0078] Such as figure 2 As shown, the lower turntable 2 is installed on the verification platform 1, such as Figure 4 As shown, the lower turntable 2 is composed of a base 22 and a lower turntable 23, and the rotating shaft 24 on the lower turntable 23 is sleeved on the rolling bearing 25 on the base 22;

[0079] Install the bottom two-dimensional manual translation adjustment platform 4 with the adapter flange 3 on the lower turntable 23, and install the mounting seat 6 of the angle measuring device 7 to be verified with the adapter flange 5 on the bottom two-dimensional manual translation adjustment platform 4;

[0080] The angle measuring device 7 to be tested is an annular angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com