Quality testing device for motorized spindle rotor

A detection device and motorized spindle technology, which is applied to measurement devices, testing of mechanical components, and testing of machine/structural components, etc., can solve problems such as low efficiency, inability to detect rotor faults quickly and comprehensively, and achieve high testing accuracy. , the test depth is wide, the inspection speed is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

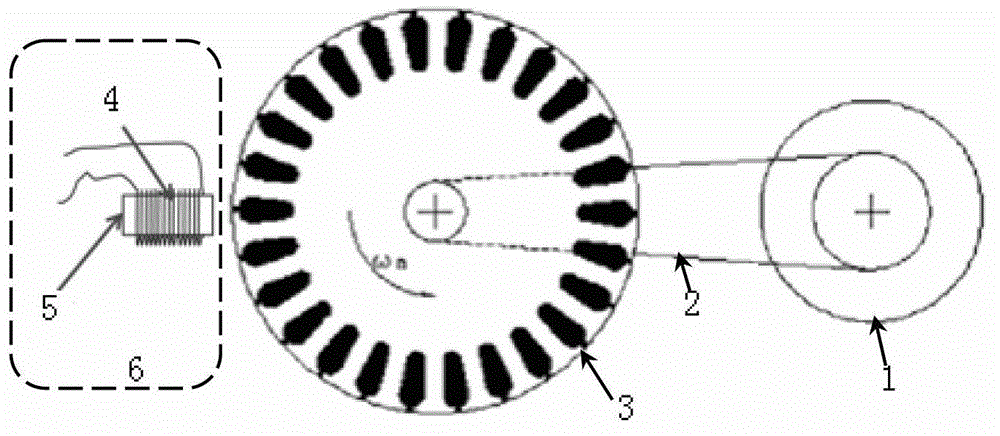

[0023] refer to figure 1 , an electric spindle rotor quality detection device, comprising a servo motor 1, the output shaft of the servo motor 1 is connected to the shaft of the rotor 3 to be tested through a transmission mechanism 2, the servo motor 1 drives the rotor 3 to be tested to rotate through the transmission mechanism 2, and the rotor to be tested is rotated by the servo motor 1. The rotor 3 is fixed on the chuck, and a permanent magnet probe 6 is arranged near the surface of the rotor 3 to be tested. The center of the permanent magnet probe 6 is on the same plane as the center of rotation of the rotor 3 to be tested.

[0024] The permanent magnet probe 6 is composed of a permanent magnet 5 and an enameled coil 4 wound on the permanent magnet 5, and both ends of the enameled coil 4 are connected to a data acquisition device to obtain signals.

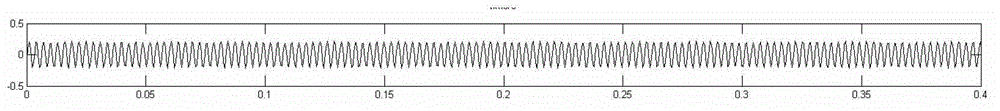

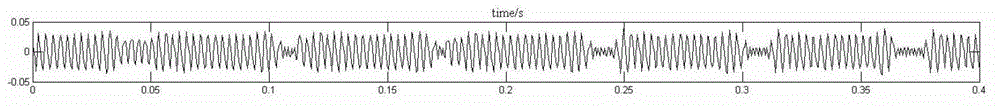

[0025] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com