Ageing rating method for T/P91 steel based on diameter of precipitated phase particle

A technology of particle diameter and precipitated phase, which is applied in the field of aging rating of T/P91 steel based on the particle size of precipitated phase, can solve the problems of quality evaluation and process researcher confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

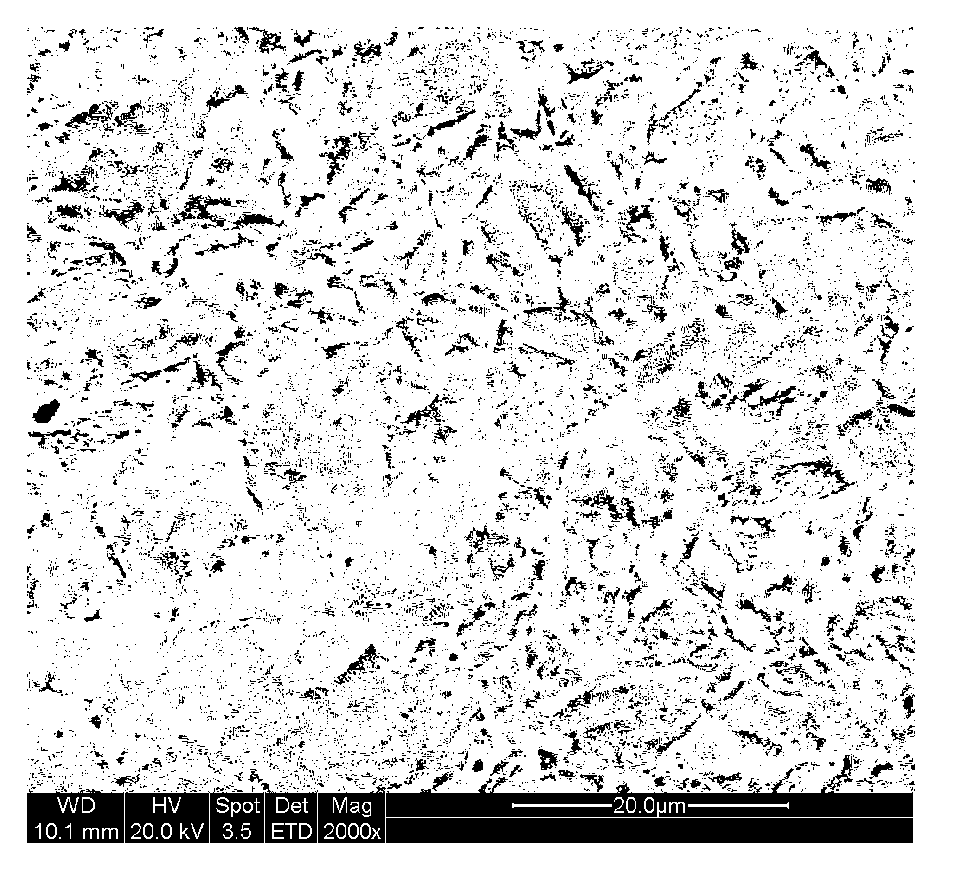

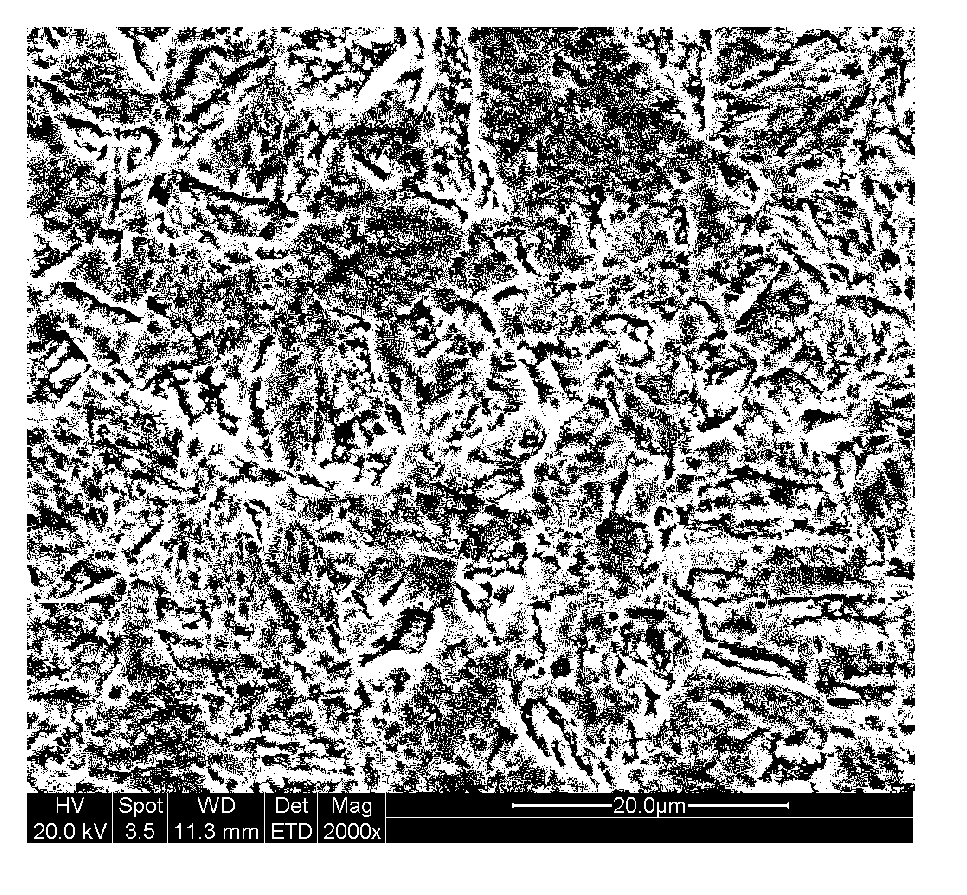

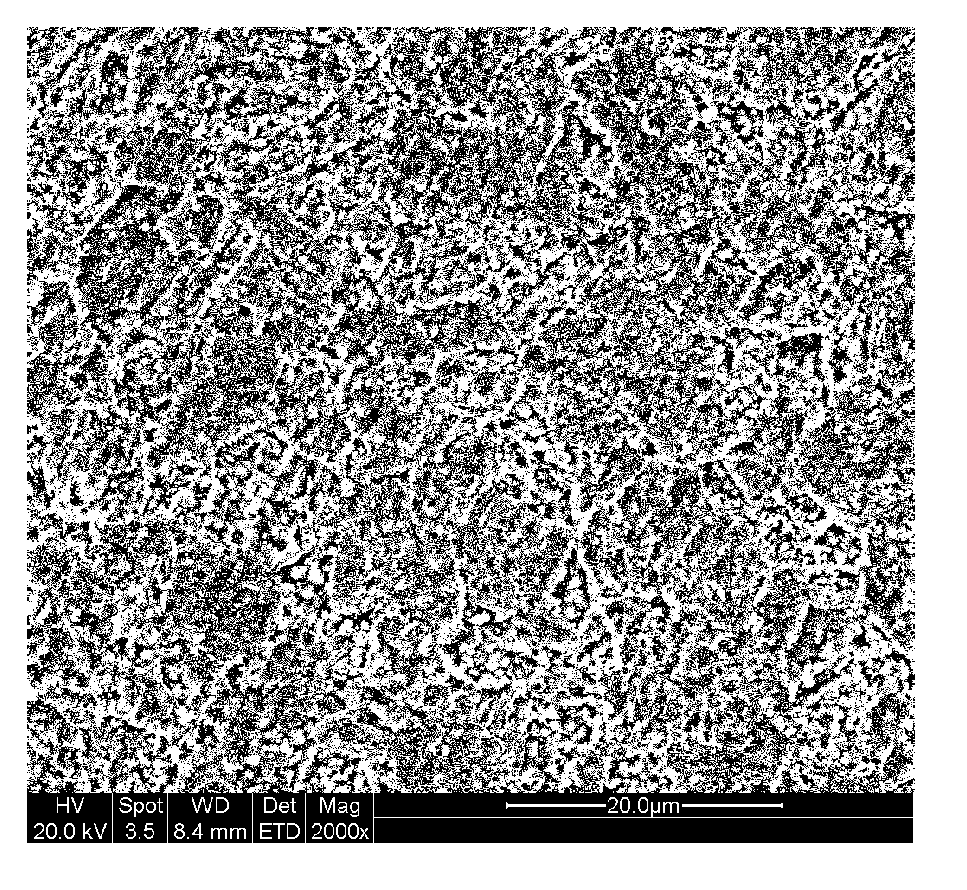

[0024] Take the T91 steel pipe for the subcritical boiler reheater actually operated in a power plant in Anhui. The operating temperature is 570°C, the pressure is 17.0MPa, the size is Ф65mm×5mm, and the operating time is 43,000 hours.

[0025] The aging of the T / P91 steel based on the particle diameter of the precipitated phase is now rated. The rating method includes the following steps:

[0026] (1) Prepare a sample of T / P91 steel to be evaluated, cut a section of T / P91 steel with a length of 10mm, a width of 5mm, and a height of 5mm as a sample to be evaluated, and use 200#~400#~600#~800#~1200 Grind the surface of the sample to be evaluated with #~1600#~3000# metallographic sandpaper, and grind each time until the direction of the scratches on the surface of the sample to be evaluated is consistent;

[0027] (2) Perform mechanical polishing on the ground sample to be evaluated until there are no scratches on the surface of the sample to be evaluated;

[0028] (3) Put the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com