Miniature double-pole fast-cutting intelligent integrated electrode without damaging rock coupling and application method thereof

A technology of integrated electrodes and polarized electrodes, which is applied in the field of micro-bipolar fast-cut non-destructive rock coupling intelligent integrated electrodes, can solve the problems of unsatisfactory coupling effect, long time consumption, and low work efficiency, and achieve low change efficiency and save energy. Probe time, effect of improving coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

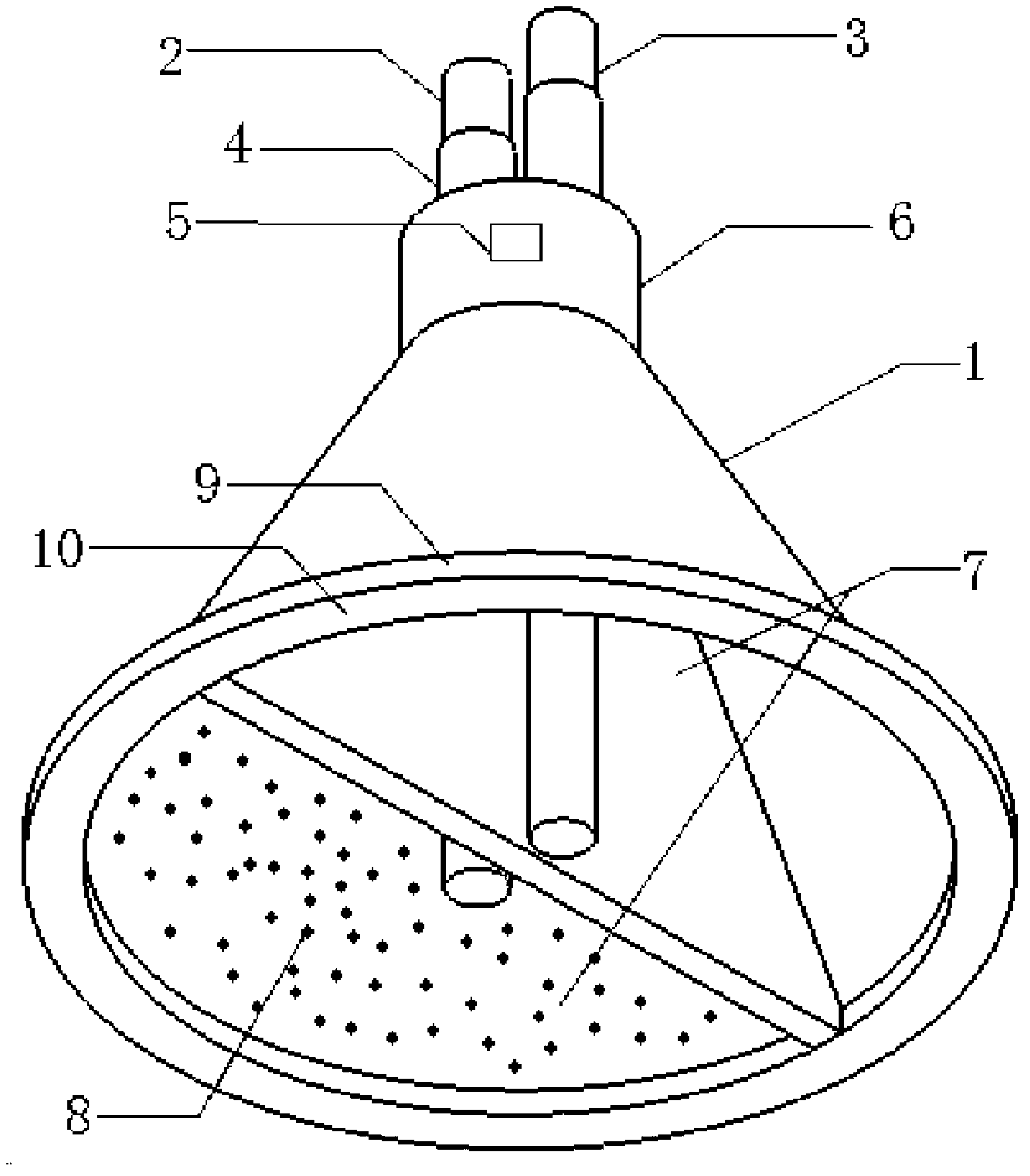

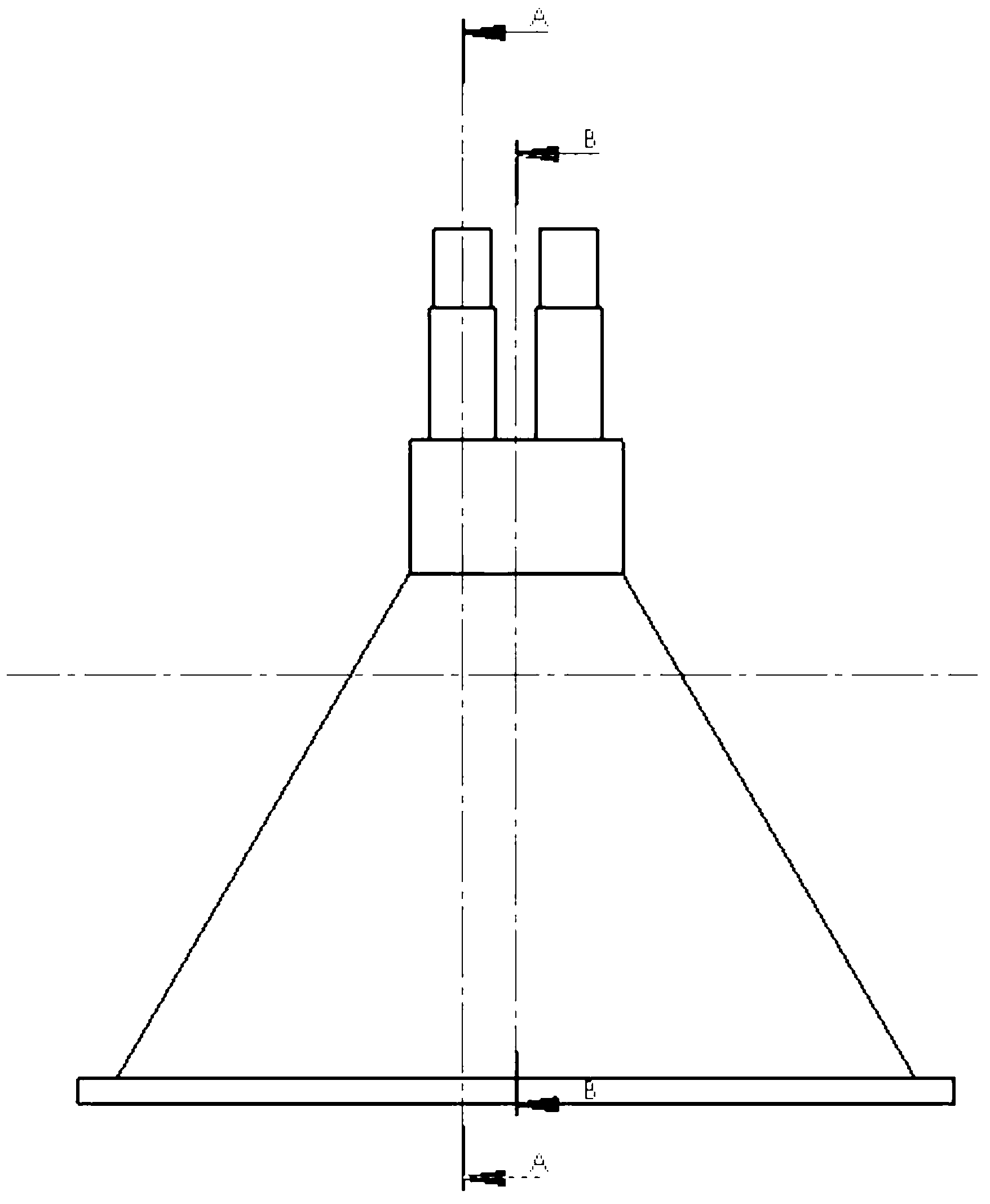

[0043] Such as figure 1As shown, a non-polarized electrode rod 2 and a metal electrode rod 3 are installed on the main support structure 1 of the miniature bipolar fast-cutting non-destructive rock coupling intelligent integrated electrode of the present invention. When installing or replacing the electrode rod, put the controller package cover 6 on Figure 7 , Figure 8 As shown in the pipe seam screw structure 4 nuts, loosen the pipe seam to open, pull out the old electrode rod, insert the new electrode rod, connect the lead wire of the electrode rod with the electrode controller 5 in the controller package cover 6, and tighten it. The nut is fixed; when the length of the electrode rod must be adjusted according to the coupling conditions of the rock mass surface, just refer to the above operation. When the present invention is arranged on the roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com