Airplane steering engine servo system fault detection method

A servo system and fault detection technology, which is applied in the field of aviation flight control, can solve the problems of high cost, complex structure, large volume and weight, etc., and achieve the effects of reducing manufacturing and maintenance costs, simplifying hardware circuits, and reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

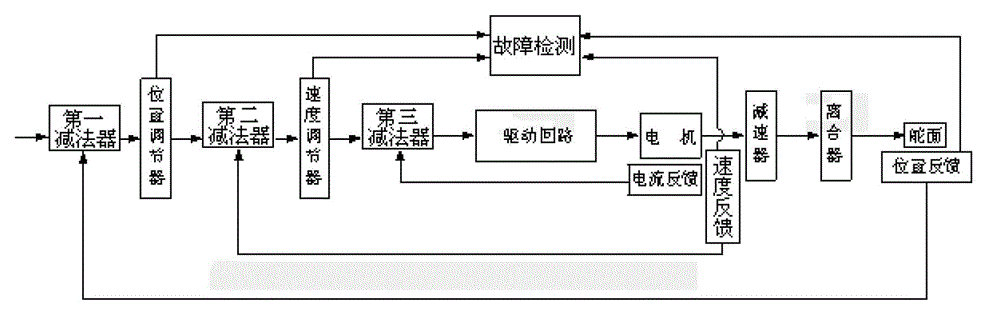

[0028] The present invention will be described in further detail below. A method for fault detection of an aircraft steering gear servo system, based on the aircraft steering gear servo system, the steering gear servo system consists of a first subtractor, a position regulator, a second subtractor, a speed regulator, a third subtractor, and a drive circuit , a motor, a reducer, a clutch, a steering surface, a current feedback sensor, a speed feedback sensor and a position feedback sensor; the first input end of the first subtractor is connected to the position command signal output end of the steering gear servo system controller, and the first The second input end of the subtractor is connected with the rudder surface position signal output end of the position feedback sensor installed on the rudder surface, the output end of the first subtractor is connected with the signal input end of the position regulator, and the signal output end of the position regulator Connect with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com