Manufacturing process of mobile phone glass cover plate

A technology of glass cover and manufacturing process, which is applied to the structure of telephones, etc., can solve problems such as high cost, inconvenient use, blurring, etc., and achieve the effects of saving use cost, improving practicability, and reducing reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described below in conjunction with accompanying drawing.

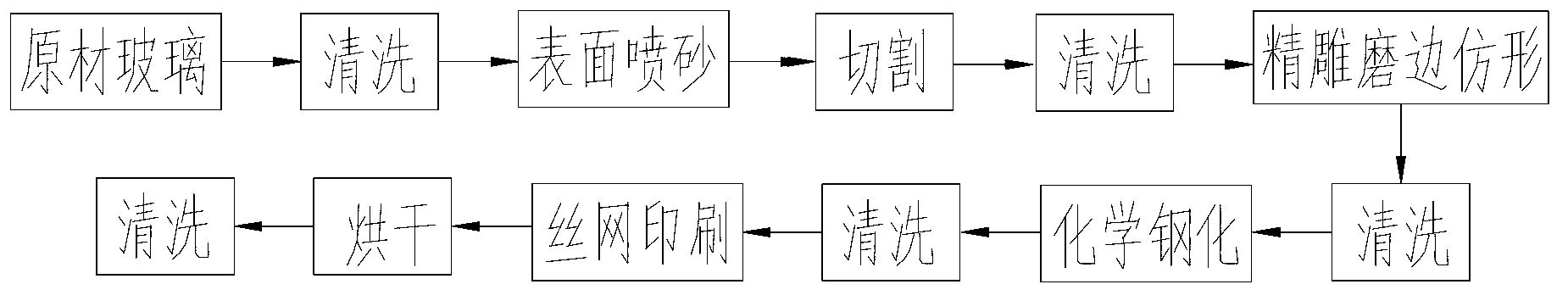

[0021] as attached figure 1 Shown is the manufacturing process of a kind of mobile phone glass cover plate of the present invention, comprises the following steps:

[0022] The first step is to clean the original glass: select the white glass of the original material, clean it, and obtain the original glass A;

[0023] The second step, frosting treatment: use the surface sandblasting process to carry out the surface frosting treatment on the raw glass A after the step 1 treatment, and obtain the frosted glass B;

[0024] The third step, glass cutting: cut the frosted glass B treated in the second step into a mobile phone glass cover C of the required appearance size;

[0025] The fourth step, cleaning: clean the glass cover plate C of the mobile phone after the treatment in step three;

[0026] The fifth step, fine carving and edging and profiling: use CNC machine tools to carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com