Elastic polyester imitated natural silk textile fabric and preparation method thereof

A technology of textile fabrics and imitation silk, which is applied in the field of textile fabrics, can solve the problems of imitation silk hygroscopicity and poor dyeing performance, and achieve the effects of improving gloss and softness, good moisture absorption and air permeability, and reducing reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

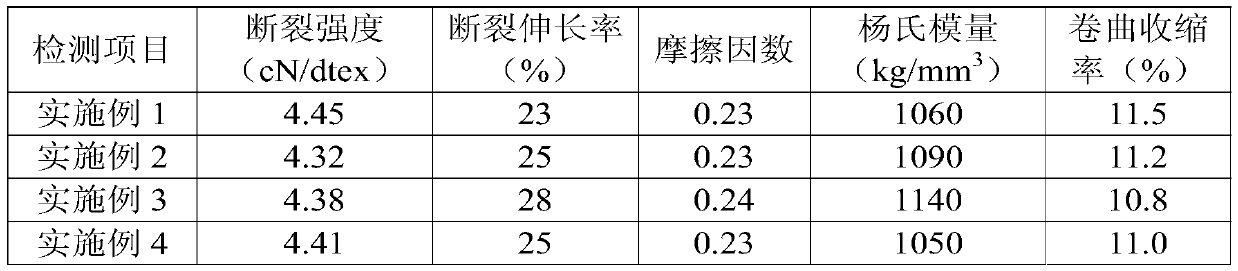

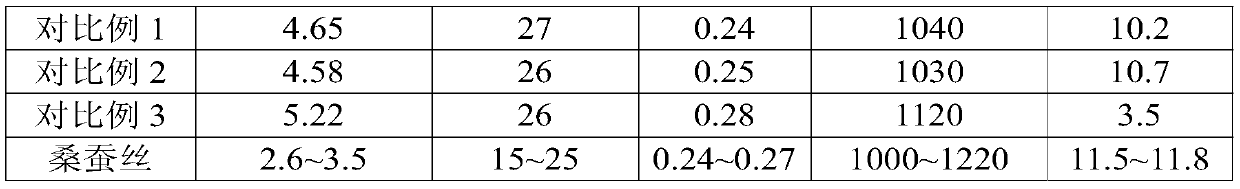

Examples

Embodiment 1

[0031] A kind of elastic polyester imitation silk textile fabric, is prepared by following method:

[0032] Step S10, pre-crystallize and dry the polyester slices and montmorillonite respectively, heat the dehumidified air through the heating system, raise the air temperature to 173°C, and dry for 6 hours, and control the water content of the polyester slices to less than 40ppm after the polyester slices are vacuum-dried; The performance parameters of the above-mentioned polyester chips are: the intrinsic viscosity of the chips is 0.62dL / g, the melting point is 264°C, the moisture content is 0.28%, the hydroxyl content is 33mol / t, and the weight ratio of the polyester chips to montmorillonite is 100:4.5;

[0033] Step S20, mix the polyester slices obtained in step S10 with montmorillonite, and put them into a screw extruder to melt. The temperature of each section of the screw extruder is: 270°C for the first stage, 290°C for the second stage, 300°C for the third stage, and 300...

Embodiment 2

[0040] A kind of elastic polyester imitation silk textile fabric, is prepared by following method:

[0041] Step S10, pre-crystallize and dry the polyester slices and montmorillonite respectively, heat the dehumidified air through the heating system, raise the air temperature to 168°C, and dry for 6 hours, and control the water content of the polyester slices to less than 40ppm after the polyester slices are vacuum-dried; The performance parameters of the above-mentioned polyester chips are: the intrinsic viscosity of the chips is 0.6dL / g, the melting point is 260°C, the moisture content is 0.2%, the hydroxyl content is 30mol / t, and the weight ratio of polyester chips to montmorillonite is 100:1.2;

[0042] Step S20, mix the polyester slices obtained in step S10 with montmorillonite, and put them into a screw extruder to melt. The temperature of each section of the screw extruder is: 260°C for the first section, 270°C for the second section, 275°C for the third section, and 275...

Embodiment 3

[0049] A kind of elastic polyester imitation silk textile fabric, is prepared by following method:

[0050] Step S10, pre-crystallize and dry the polyester slices and montmorillonite respectively, heat the dehumidified air through the heating system, raise the air temperature to 178°C, and dry for 6 hours. After the polyester slices are vacuum-dried, the water content of the polyester slices is controlled to be less than 40ppm; The performance parameters of the above-mentioned polyester chips are: the intrinsic viscosity of the chips is 0.65dL / g, the melting point is 268°C, the moisture content is 0.35%, the hydroxyl content is 35mol / t, and the weight ratio of the polyester chips to montmorillonite is 100:7.8;

[0051] Step S20, mix the polyester slices obtained in step S10 with montmorillonite, and put them into a screw extruder to melt. The temperature of each section of the screw extruder is: 285°C for the first section, 305°C for the second section, 320°C for the third sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com