Saw-blade saw bit with bionic sawteeth for cutting maize straws

A technology of corn stalks and sawtooth, applied to cutting equipment, applications, harvesters, etc., can solve problems such as friction and wear, complexity, and failure of working parts of cutting machines, and achieve reduced power consumption, improved wear resistance and work efficiency, and reduced The effect of the pinch saw phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

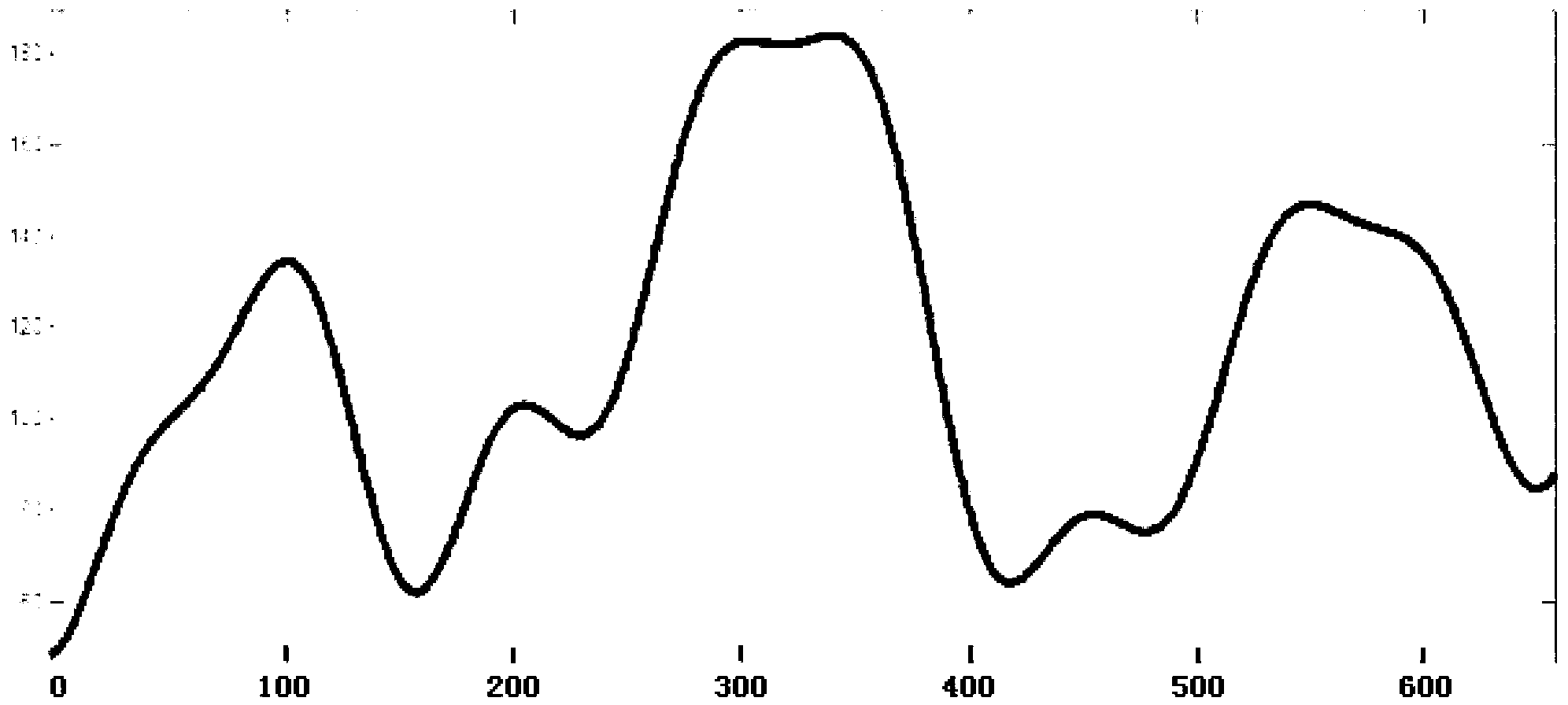

[0018] Such as figure 2 As shown, this example is a reciprocating saw blade that is continuously arranged in a straight line and imitates the curved sawtooth structure of the outer edge of the cotton locust cutting teeth for cutting corn stalks. Its characteristics are: the outer edge of the cotton locust cutting teeth is in a linear continuous array. , the length of the saw teeth on the saw blade is 375 mm, and there are 24 sets of saw tooth units imitating the outer edge contour curve of the cotton locust cutting teeth on this length.

Embodiment 2

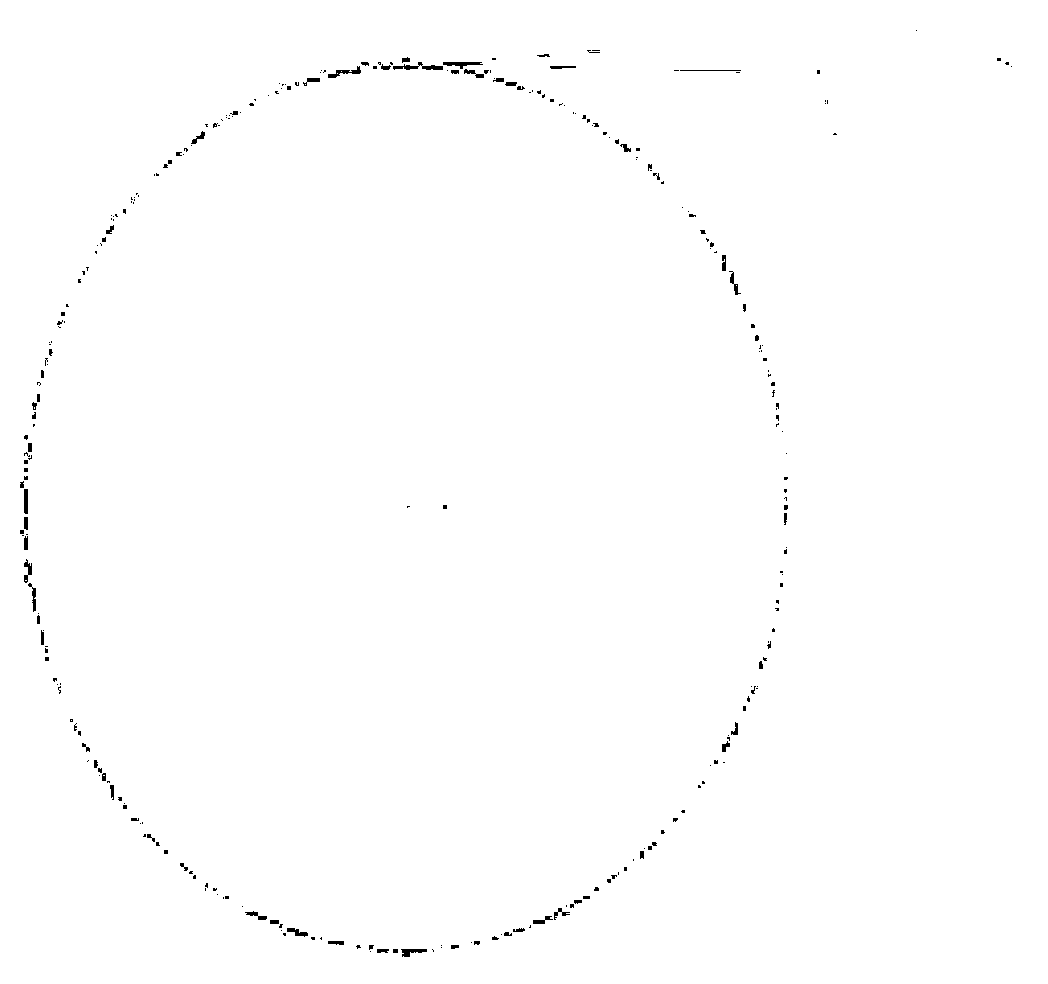

[0020] Such as image 3 As shown, this example is a rotary circular saw blade with a ring-shaped continuous arrangement for cutting corn stalks imitating the curved sawtooth structure of the outer edge of the cutting teeth of the cotton locust. Ring-shaped continuous array, the radius of the circular saw is 280 mm, and there are 58 groups of sawtooth units imitating the outer edge contour curve of the cotton locust cutting teeth on the peripheral length of the circular saw.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Circle radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com