Dedusting device equipped with metal film capacitor metal spraying machine

A technology of dust removal device and capacitor, which is applied in the direction of combination device, chemical instrument and method, and separation of dispersed particles, and can solve problems such as uneven particle size of smoke and dust, poor smoke and dust treatment effect, unfavorable environmental protection and metal recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

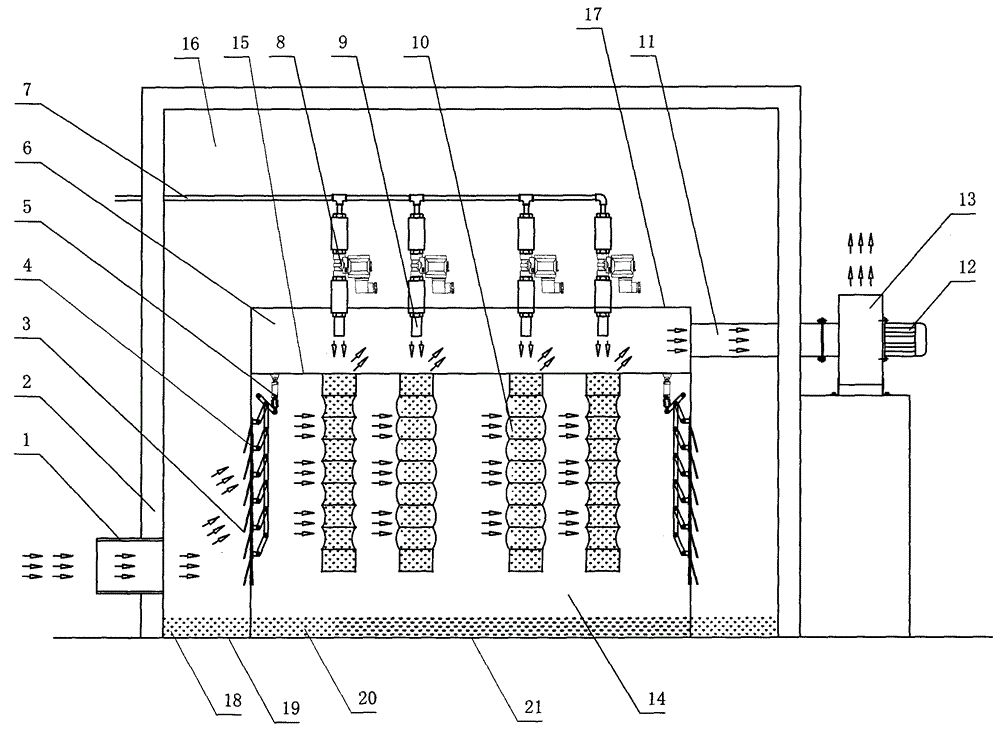

[0019] The structure of the dust removal device in the embodiment of the present invention is as follows: Figure 1~5 shown, including:

[0020] ——A sealed outer box body 2 processed by thicker materials, and its left side is provided with an air inlet 1 connected to the working room of the metal film capacitor spraying gold machine;

[0021] ——The inner box 17 of sheet metal processing located inside the outer box 2, which is separated by a horizontal metal plate 15 into a dust removal room 14 on the lower floor and a clean room 6 on the upper floor;

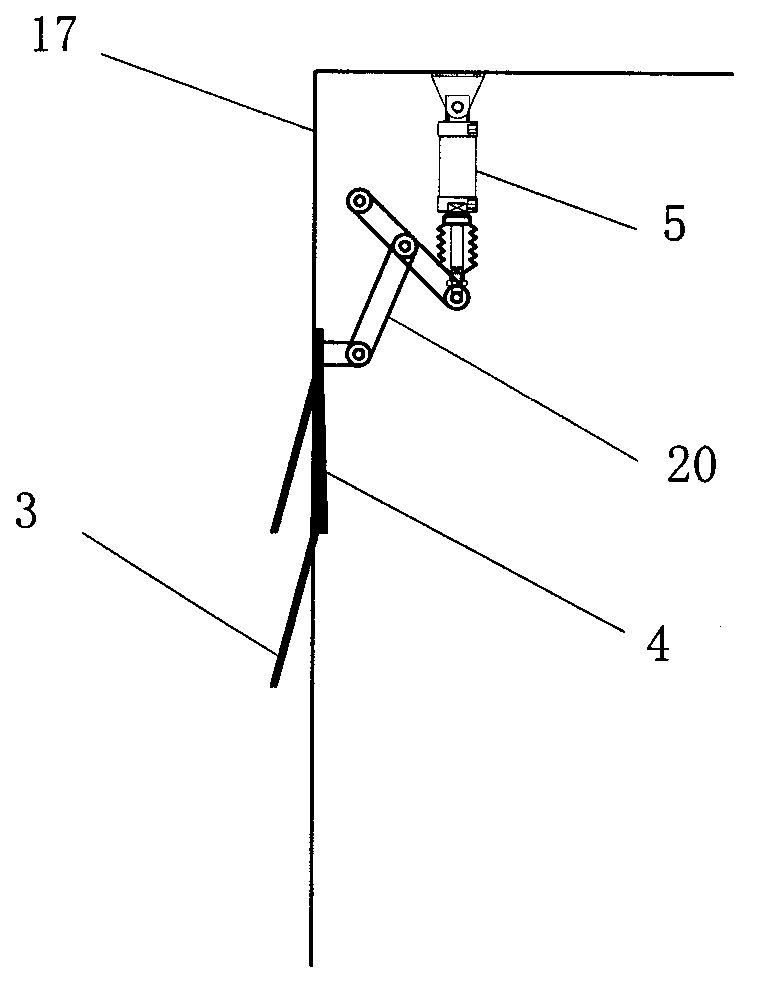

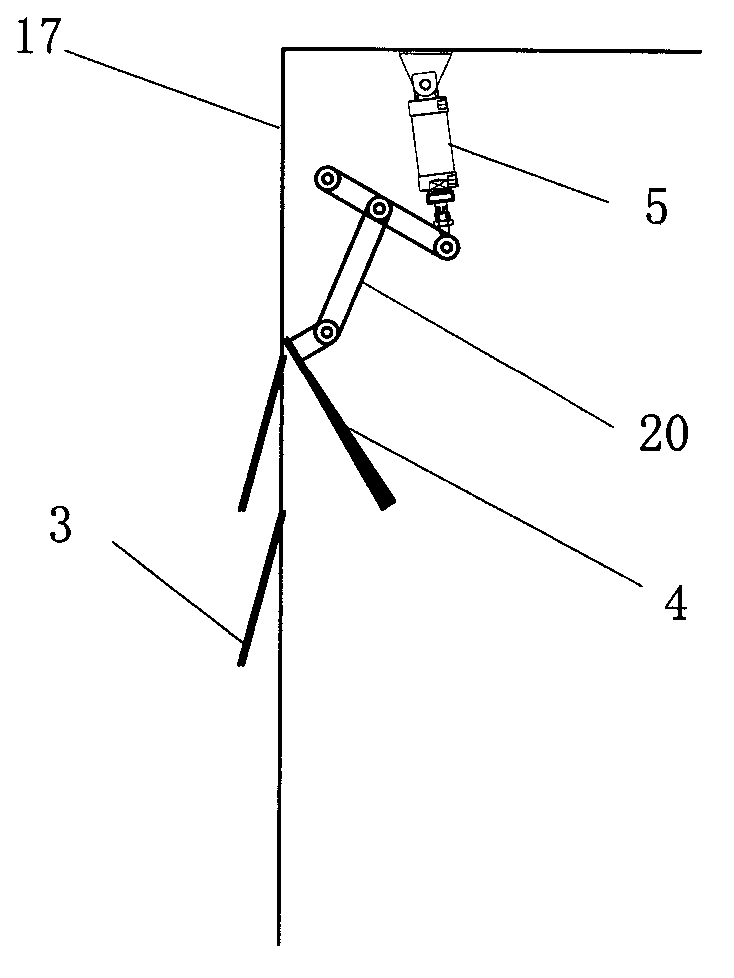

[0022] ——The left and right sides of the dust removal chamber 14 each have a louver 3 with 6 layers of openings for the air in the interlayer space 16 between the inner and outer boxes to enter obliquely upward;

[0023] ——The inner sides of the openings of each layer of the louver 3 are each closed by a horizontal row of brushes 4, and the dense wool strips in the brushes are vertically downward from the brush fixed horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com