Fast centering installing and clamping device

A clamping device and fast technology, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to guarantee brazing quality, time-consuming clamping workpiece pipe and nut joints, etc., to ensure alignment and ensure product quality quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

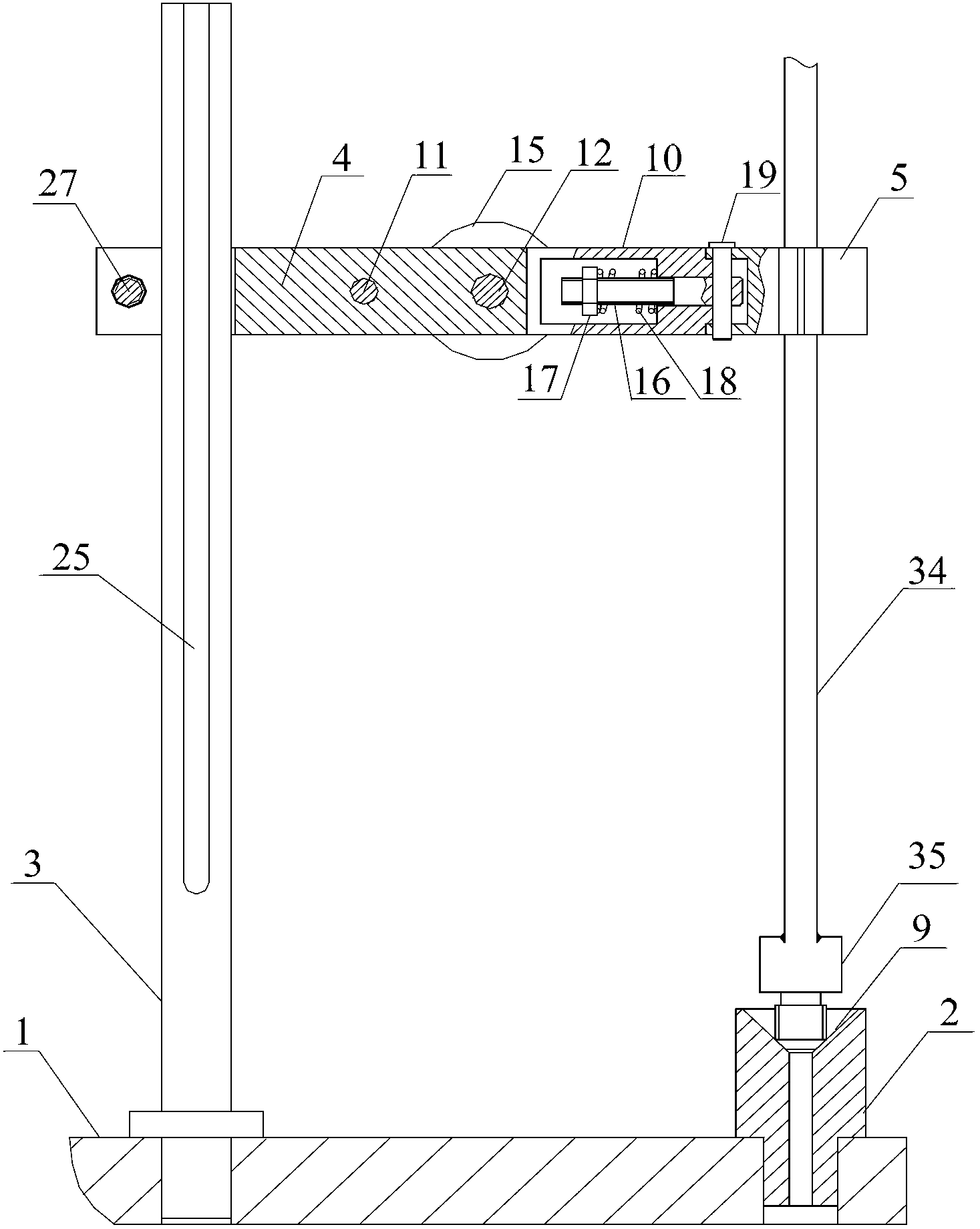

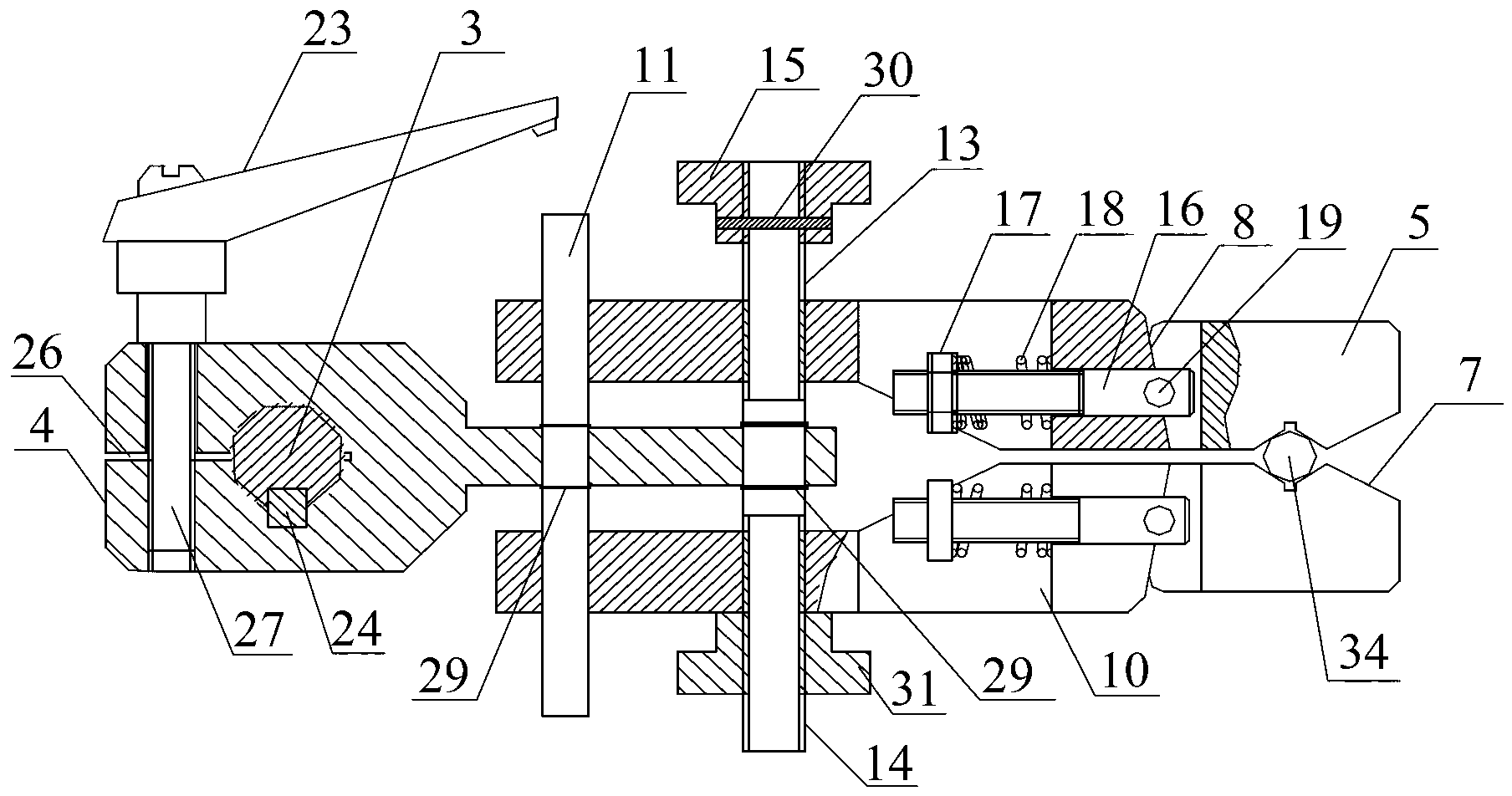

[0031] Such as Figure 1-8 As shown, the fast centering and clamping device of the present invention is mainly composed of a support plate 1, and the support plate 1 is installed on a brazing machine during use, so that the present invention is used in conjunction with the brazing machine. In order to support the positioning nut joint 35 conveniently, a base 2 is provided on the support plate 1 , and a recess 9 is also provided on the base 2 . Described recess 9 is the conical shape that cooperates with the outer conical surface of nut joint 35 bottoms, as figure 1 shown. During installation, the nut joint 35 is supported and positioned on the base 2 through the coaxial cooperation between the bottom outer conical surface of the nut joint 35 and the inner conical surface of the recess 9 of the base 2 .

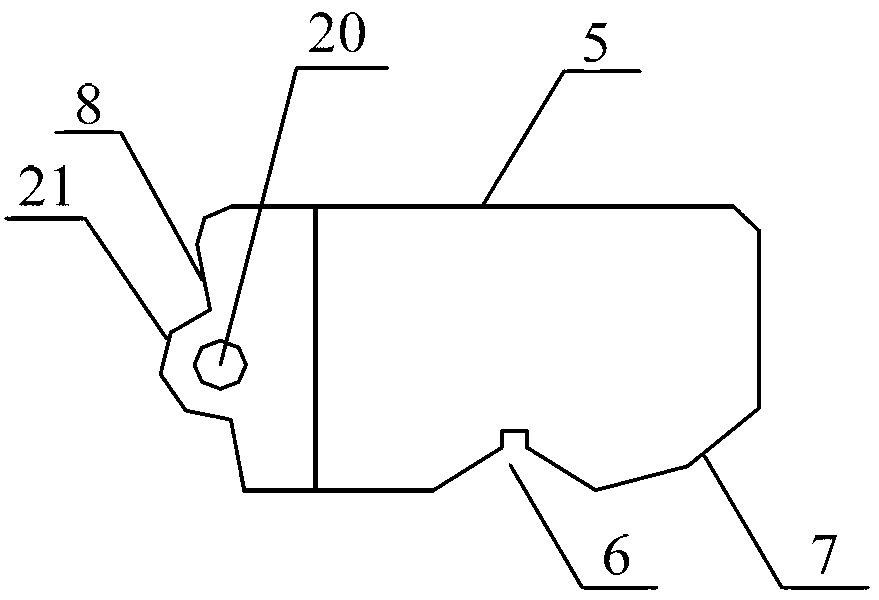

[0032] In order to facilitate the clamping of the workpiece tube 34, so that the workpiece tube 34 and the nut joint 35 are sealed and connected by welding after the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com