Continuous production method and device of acidic and neutral transparent sealing silicone adhesive

A production method and production device technology, which are applied in the field of liquid silicone rubber production technology, can solve problems such as easy skinning, poor reliability, and easy damage to seals, so as to avoid cumbersome pressurization steps, avoid equipment damage, and improve yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiment of the present invention provides a continuous production method and device for acidic and neutral transparent sealing silicone glue, which is used to effectively improve product quality.

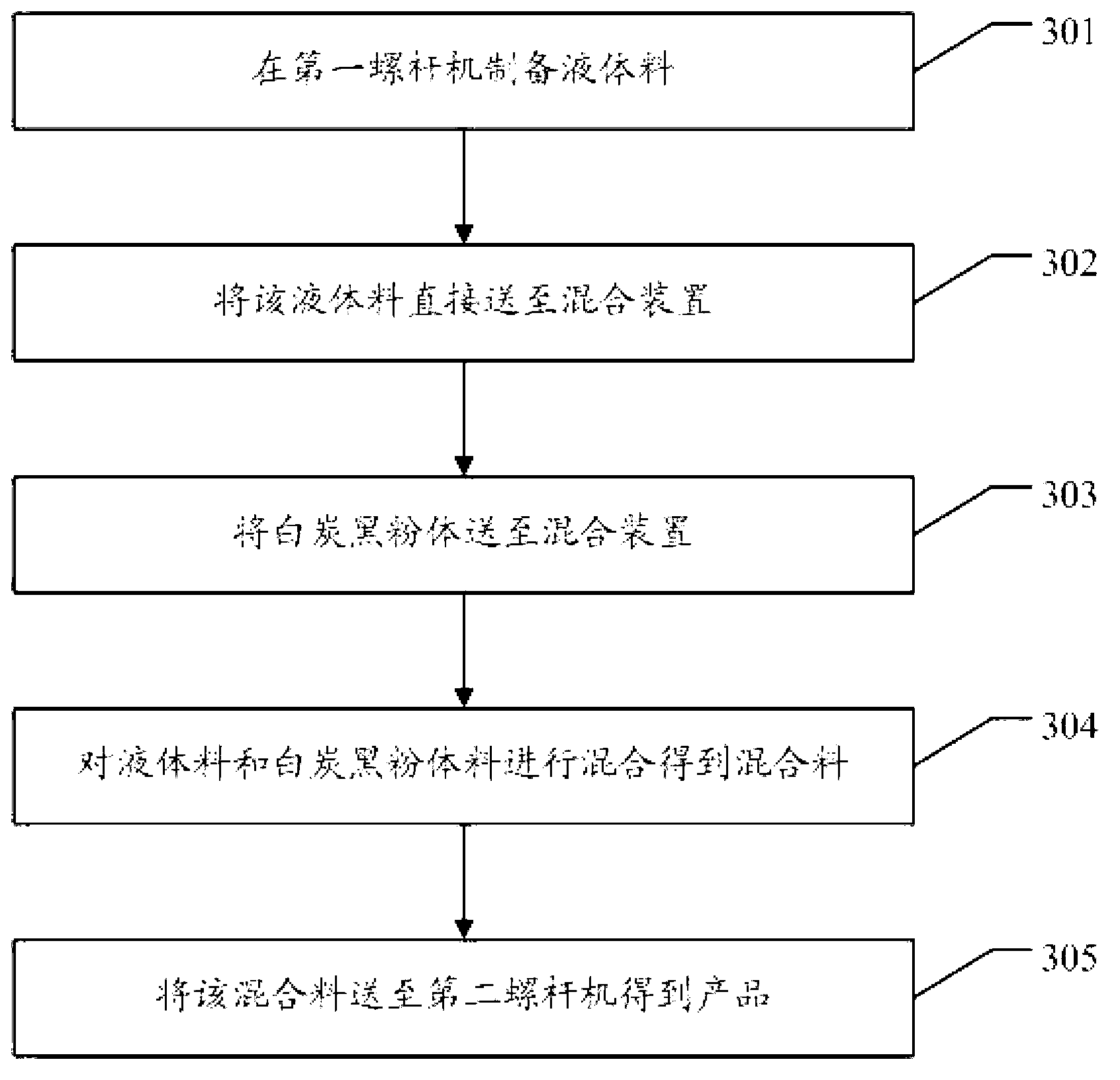

[0040] see image 3 The embodiment of the continuous production method of acidic and neutral transparent sealing silicone glue provided by the embodiment of the present invention specifically includes:

[0041] 301. Prepare liquid material in the first screw machine;

[0042] In this embodiment, in the first screw machine, the 107 glue, the first auxiliary agent, white oil and silicone oil are mixed, dispersed and vacuumized, and the liquid material is obtained after the temperature is lowered by the cooler.

[0043] It should be noted that at least one opening is opened on the first screw machine for vacuuming.

[0044] 302. Send the liquid material directly to the mixing device;

[0045] In this embodiment, the need to use a special powder pressurizing device in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com