Prefabricated concrete template, prefabricated building comprising same and construction method of template

A technology of prefabricated concrete and concrete, applied in the direction of building structure, construction, building materials, etc., can solve the problems of slow construction speed, high construction cost, and many processes, and achieve the effect of low cost and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

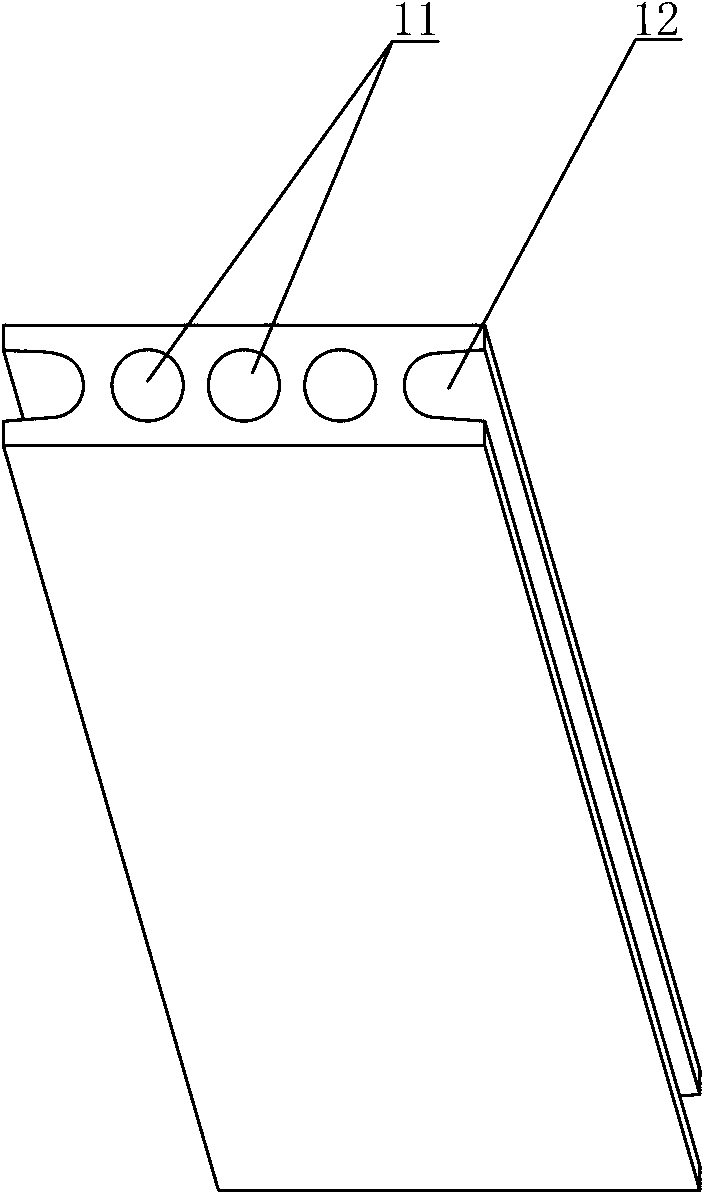

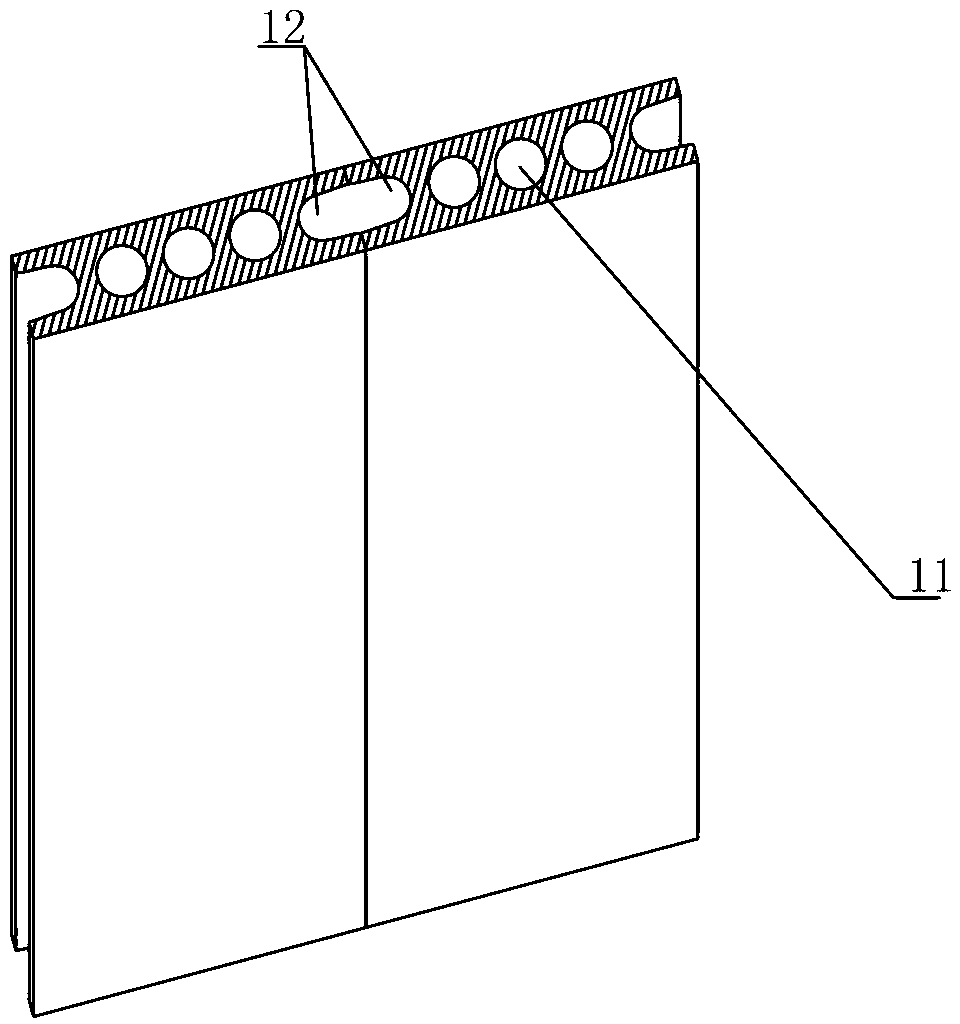

[0037] Such as figure 1 As shown, the prefabricated concrete formwork of this embodiment is a planar formwork, which is prefabricated by concrete. The body of the formwork is provided with through holes 11 along the length direction, and two opposite sides of the planar formwork form are provided with two Through the groove 12, the cross section of the through hole 11 is circular, and the cross section of the groove 12 is semi-elliptical, such as figure 2 As shown, when the two sides with grooves 12 of two planar templates are butted, the two grooves 12 are butted to form a closed hole.

[0038] The length of the planar formwork is 2000mm~4000mm, the thickness is 100mm~200mm, and the width is 400mm~1000mm.

Embodiment 2

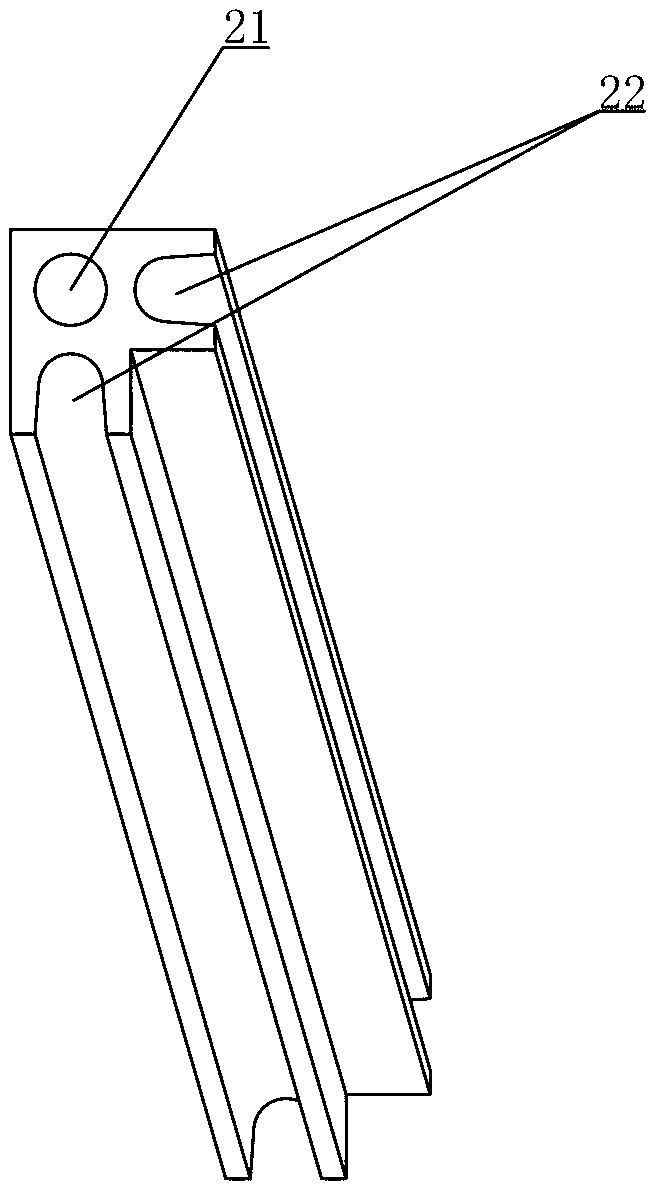

[0040] Such as image 3 , 4 As shown, the prefabricated concrete formwork of this embodiment is an "L" type formwork, which is prefabricated by concrete. The body of the formwork is provided with through holes 21 along the length direction, and two adjacent sides of the "L" formwork form are provided with two A groove 22 penetrating along the length direction of the template, the cross-section of the through hole 21 is circular, and the cross-section of the groove 22 is semi-elliptical.

[0041] The length of the "L" formwork is 2000mm~4000mm, the thickness is 100mm~200mm, and the width is less than 400mm.

Embodiment 3

[0043] Such as Figure 5 , 6 As shown, the prefabricated concrete formwork of this embodiment is a "T" formwork, which is prefabricated by concrete. The formwork plate is provided with through holes 31 along the length direction, and each of the three sides of the "T" formwork is provided with a The groove 32 penetrates along the length direction of the template, the cross-section of the through hole 31 is circular, and the cross-section of the groove 32 is semi-elliptical.

[0044] The length of the "T" template is 2000mm~4000mm, the thickness is 100mm~200mm, and the width is less than 400mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com