Optical fiber grating water and soil interface sensor and manufacturing and installation method thereof

A technology of optical fiber grating and water-soil interface, which is applied in the direction of displaying liquid level indicators through pressure measurement, can solve the problems of underwater turbulent flow interference, inability to accurately measure the position of water-soil interface, and the limitation of the number of probes, so as to achieve simple production and measurement principle Simple, reliable, and high-precision test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

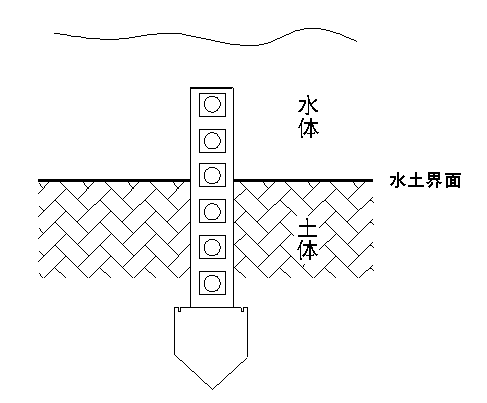

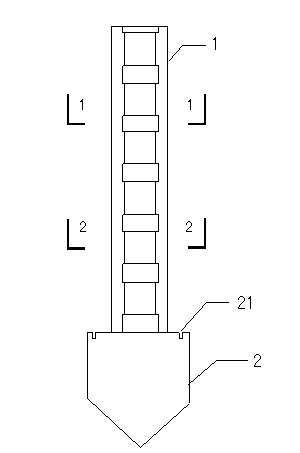

[0043] combine figure 1 , Fig. 2 and Fig. 3, the fiber Bragg grating water-soil interface sensor of the present invention includes a fixed frame and a piezometric tube.

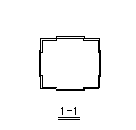

[0044] The fixing frame includes a protection section 1 and an anchor section 2 . The anchor segment 2 is fixed at the bottom of the protection segment 1 . The protection section 1 is a lattice pipe frame welded by L-shaped steel; the anchor section 2 is a steel conical cylinder with a circular fixing groove 21 on the top surface, and the protection section 1 is within the range of the fixing groove 21.

[0045] The piezometric tube includes a piezometric tube body 3, a water-permeable plate 32 and several identical fiber grating sensing probes 31, and is provided with a water injection port 33; the water-permeable plate 32 is fixed on one side of the piezometric tube body 3, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com