Automobile integrated illumination intensity sensor

A light sensor and integrated technology, applied in the field of vehicle sensors, can solve the problems of low production efficiency, complex assembly process, poor light guide performance, etc., and achieve the effects of improving production efficiency, facilitating conduction and improving light guide performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below through examples. It should be understood that the examples can only be used to explain the present invention and cannot be construed as limitations on the technical solutions of the present invention.

[0023] The following is attached Figure 1 to Figure 3 As shown, the technical solution of the present invention is described in detail.

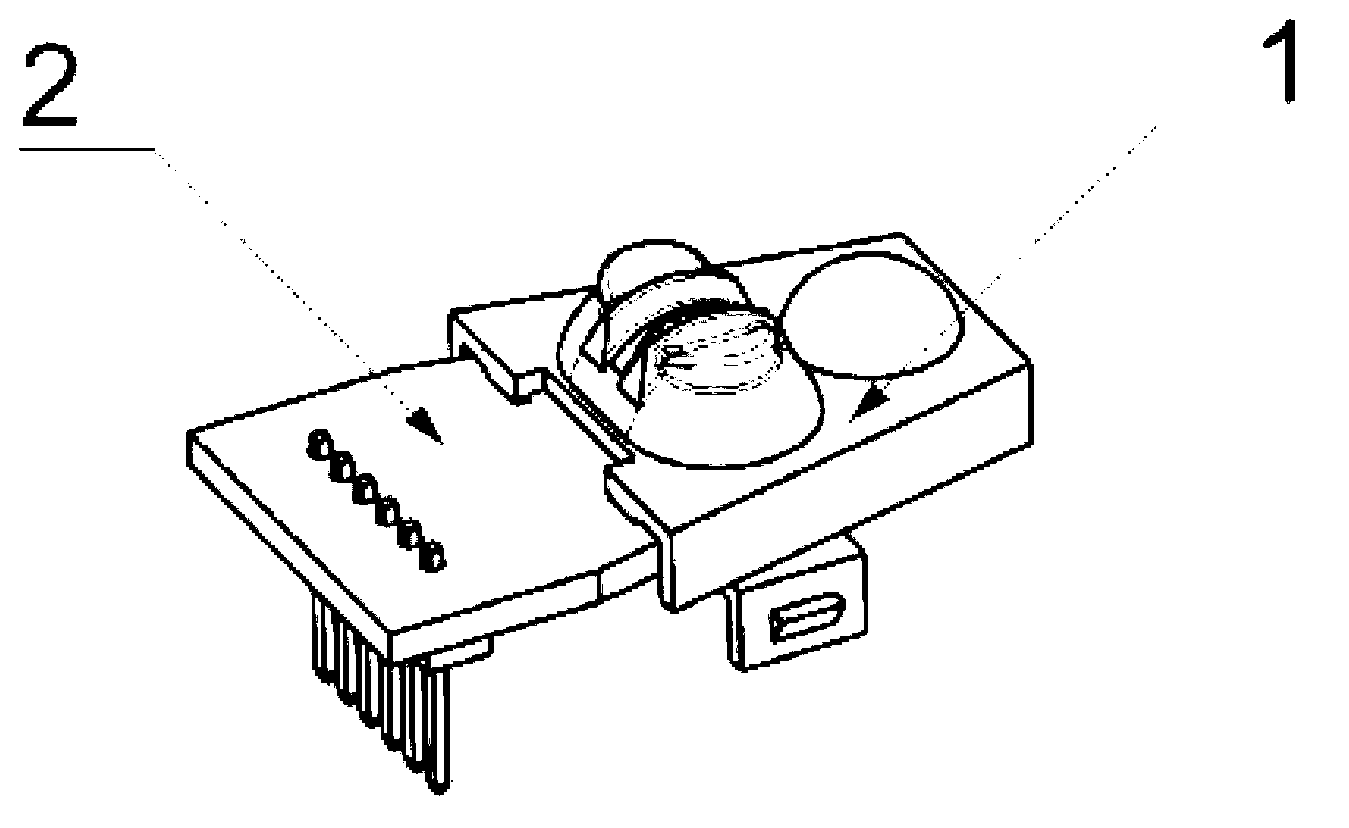

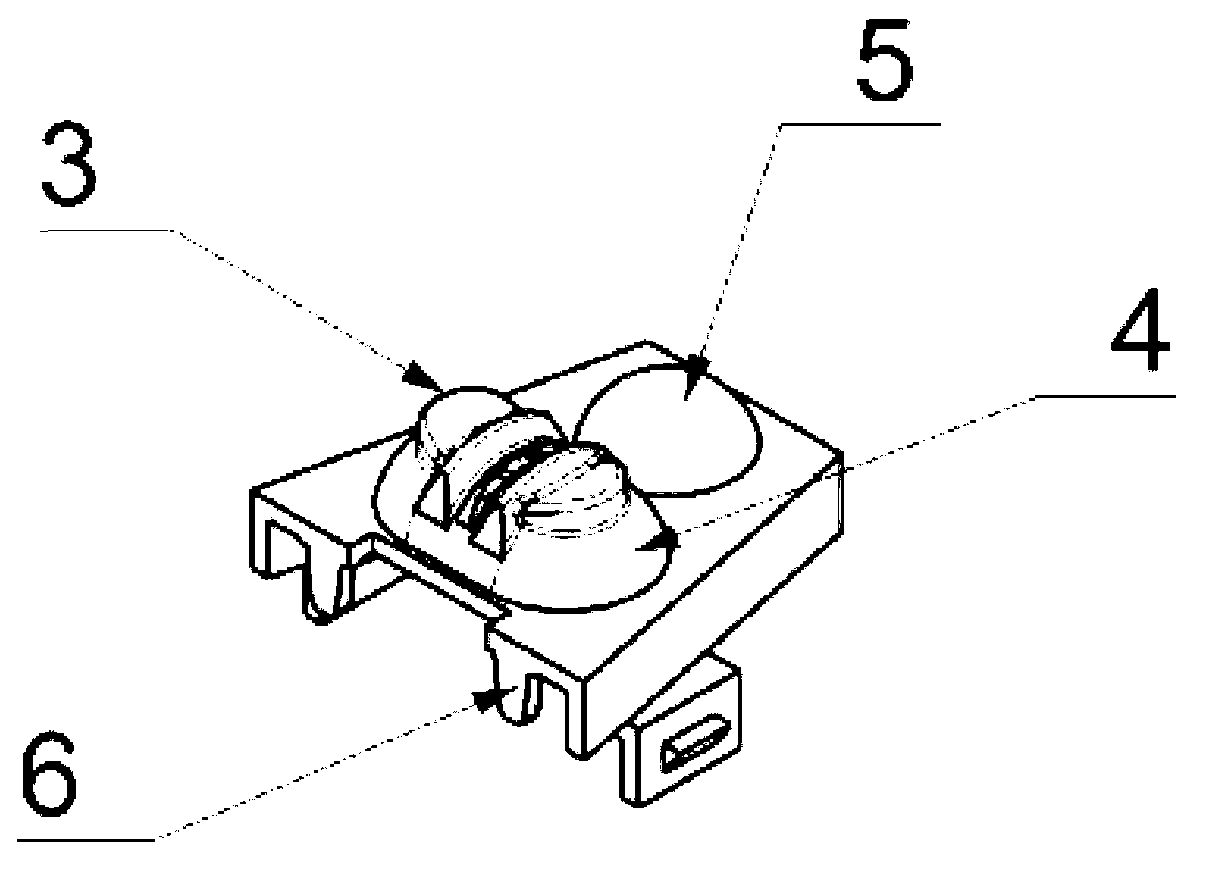

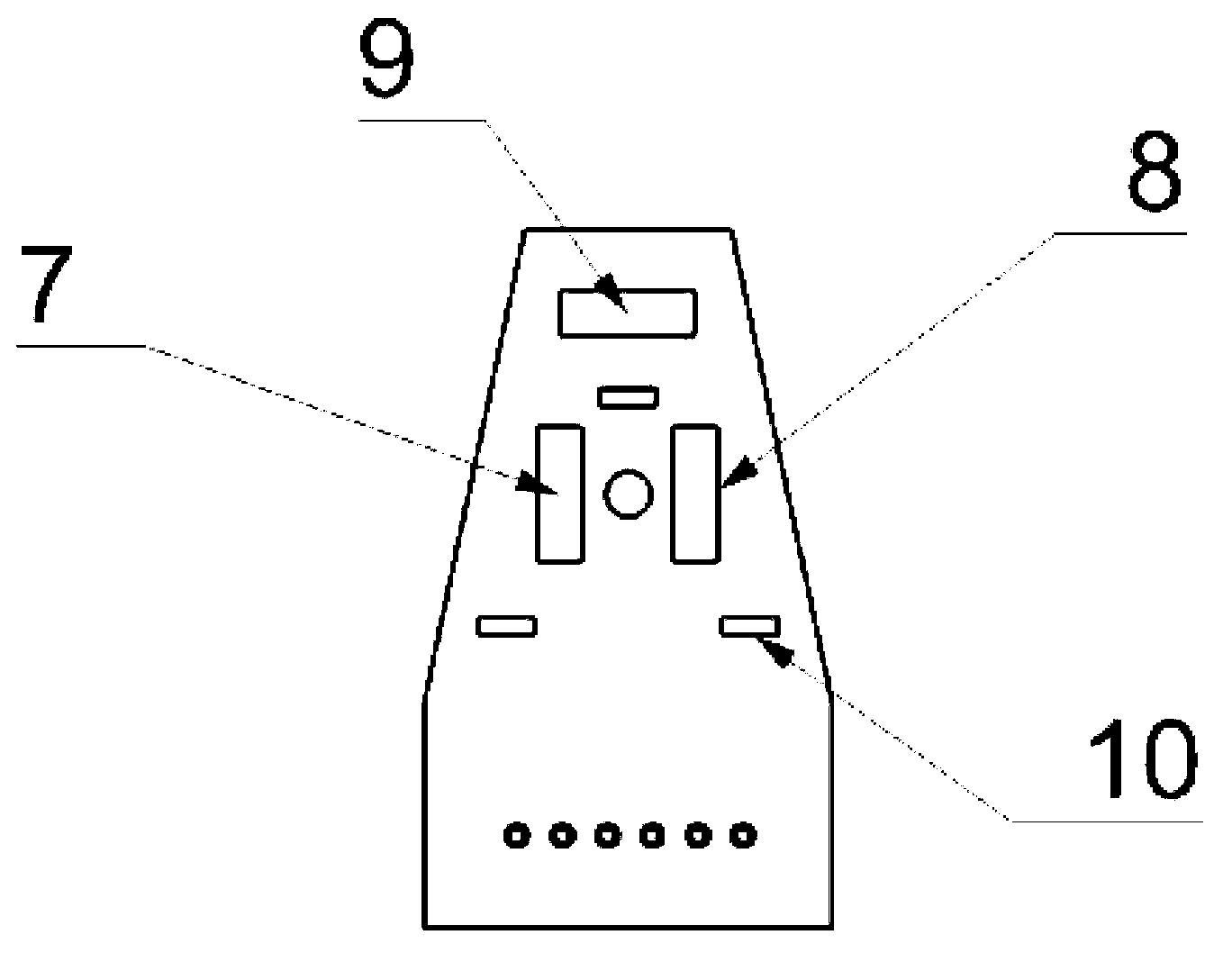

[0024] figure 1 Shown is the photosensitive assembly of the present invention, including an integrated light guide 1 and a printed circuit board 2; figure 2 Shown is an axial side view of the integrated light guide body, including the light guide structure of the left photosensitive element, the light guide structure of the right photosensitive element, the light guide structure of the front photosensitive element, and the positioning structure of the light guide body; image 3 Shown is a schematic diagram of a printed circuit board, including a lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com