Fire extinguisher cylinder pressure-resistance tightness gas detection all-in-one machine and pressure resistance and tightness testing method

A pressure-resistant sealing and fire extinguisher technology, which can be used in liquid/vacuum measurement for liquid tightness, application of stable tension/pressure to test material strength, and detection of fluid appearance at leak points, etc., which can solve rising production costs. , time-consuming and laborious, cumbersome processes, etc., to achieve the effect of eliminating personnel fatigue, reducing manufacturing costs, and reducing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

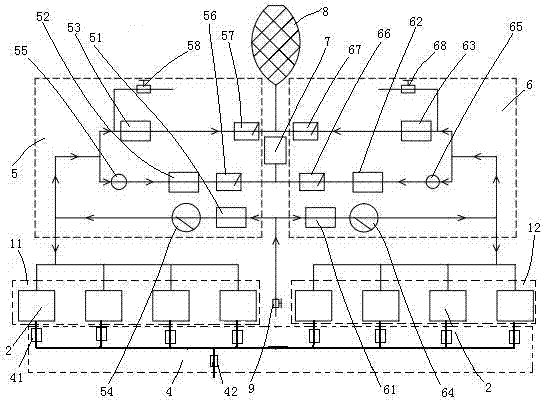

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

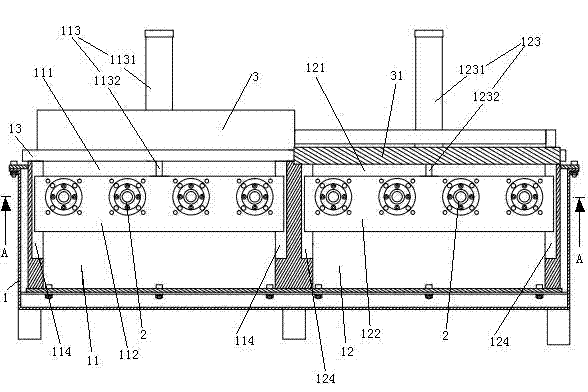

[0023] see figure 1 , a fire extinguisher cylinder pressure-resistant airtight gas measuring integrated machine, including a frame 1.

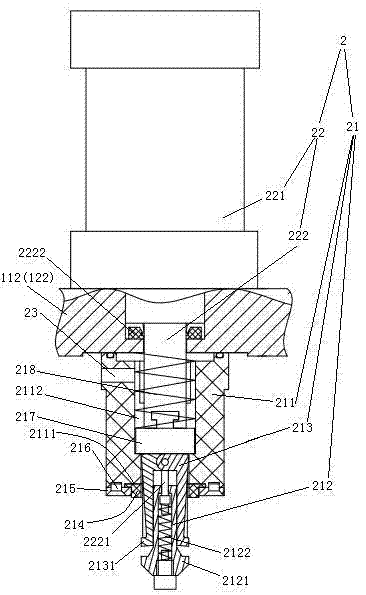

[0024]The left end of the frame 1 is provided with a left explosion-proof cavity 11 . The upper end of the left explosion-proof chamber 11 is provided with a left door opening 111 . A left lifting seat 112 is provided in the left explosion-proof chamber 11 . The left lift seat 112 is suspended in the left explosion-proof cavity 11 by the left lift cylinder 113 . The cylinder body 1131 of the left lift cylinder is fixed on the frame top wall 13 . The left lift seat 112 is fixed on the outer end of the left lift cylinder piston rod 1132, that is, the lower end in the figure. A pair of left chute 114 is arranged in the left explosion-proof chamber 11 extending along the up-down direction and distributed in the left-ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com