Digital hologram printing system utilizing secondary holography

A technology of digital hologram and printing system, applied in the field of holographic display, can solve the problems of high resolution and aberration correction, high requirements for micro lens, complex system, etc., and achieve vibration insensitivity, high-speed large-format hologram printing output , the effect of simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

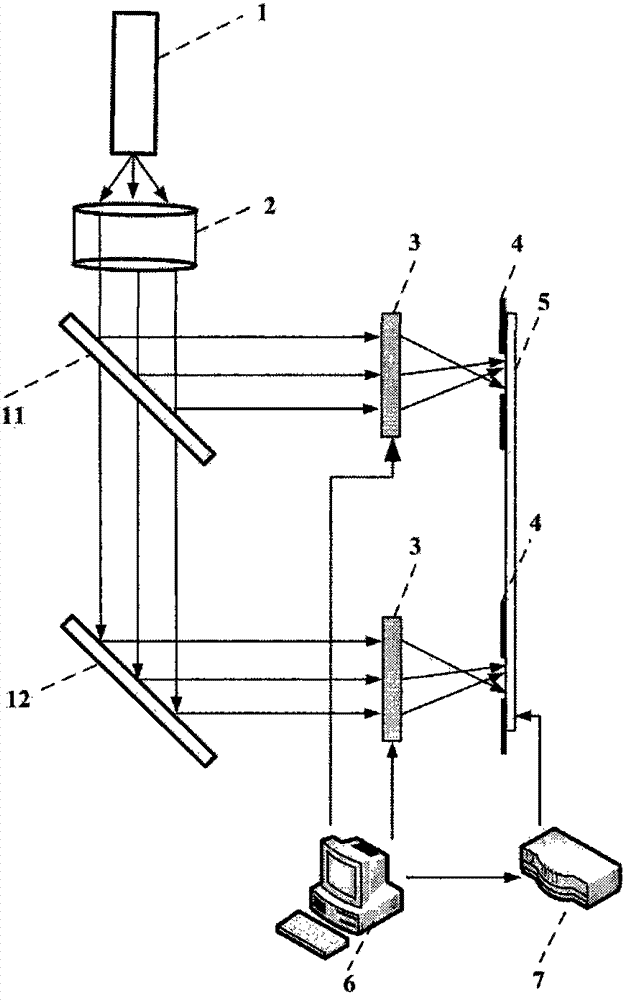

[0024] The "a digital hologram printing system using double holography" of the present invention will be further described below in conjunction with the accompanying drawings and examples.

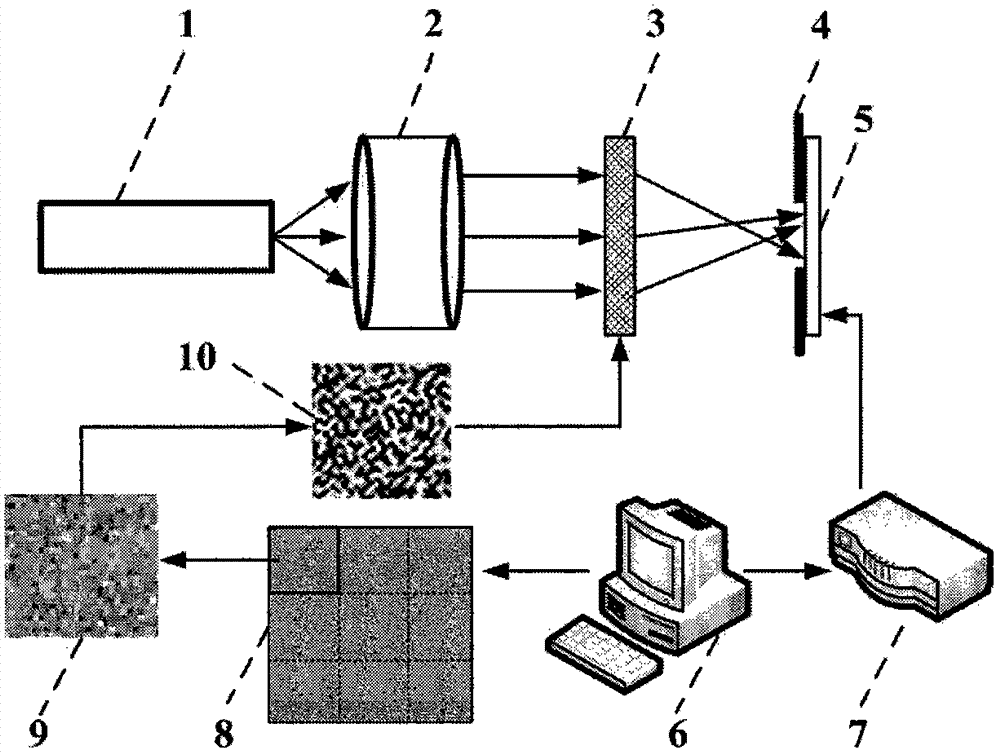

[0025] figure 1 The first embodiment of the digital hologram printing system utilizing secondary holography provided by the present invention includes a writing light source (1), a collimation system (2), a spatial light modulator (3), a rectangular aperture (4 ), hologram recording medium (5), hologram computing system (6), servo control system (7), target hologram (8), sub-hologram (9), secondary hologram (10).

[0026]In this embodiment, the target hologram (8) is generated by the hologram computing system (6), which can be generated by optical interference holography or computational holography, and the hologram computing system (6) divides the target hologram by geometric segmentation To form more than 2 sub-holograms (9), this embodiment provides a special case of dividing into 9 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com