Comb-shaped slow-wave structure for multi-band electron beam channel

A strip-shaped electronic and slow-wave structure technology, which is applied to the circuit components of time-of-flight electron tubes, can solve the problems of lack of high power and low cost, so as to improve the efficiency of injecting wave interaction, increase output power, and improve The effect of operating current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

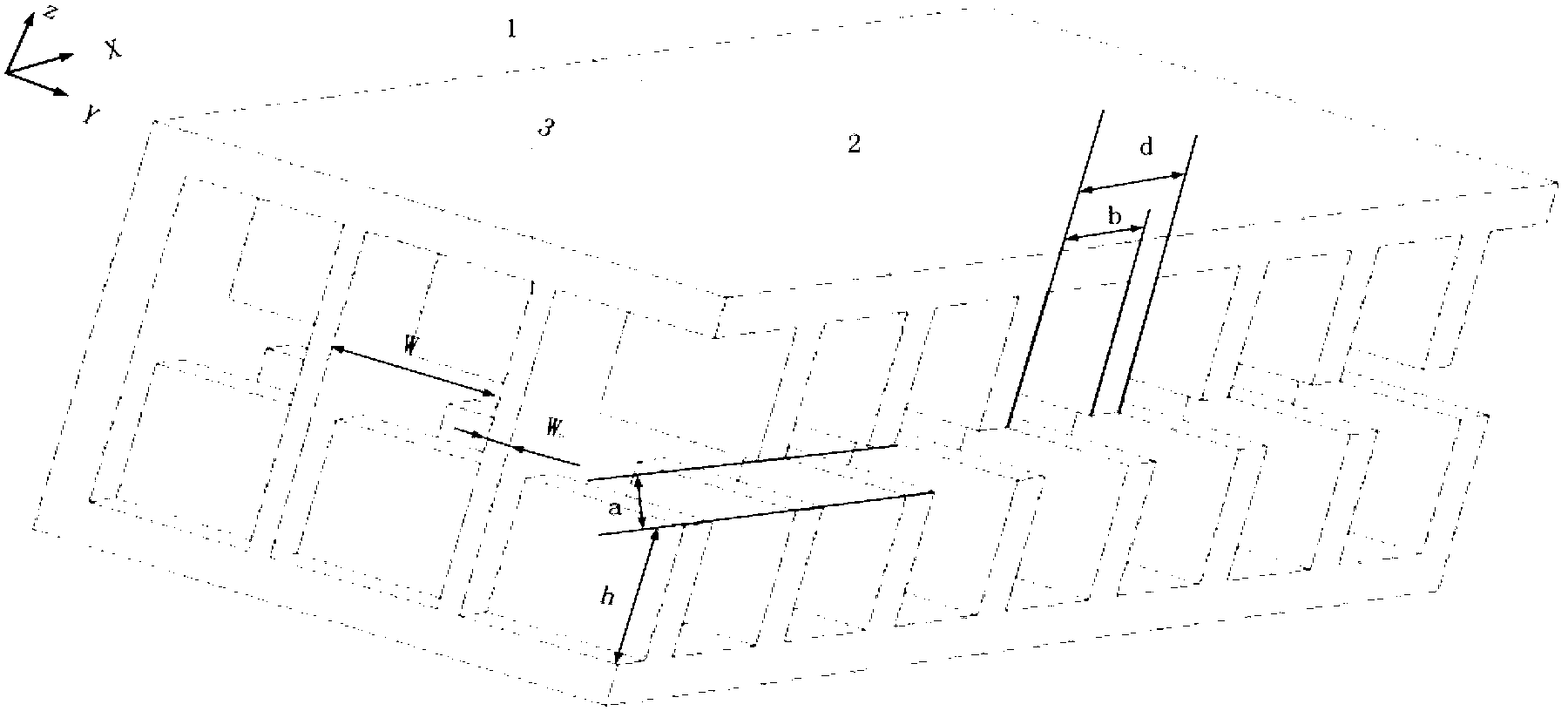

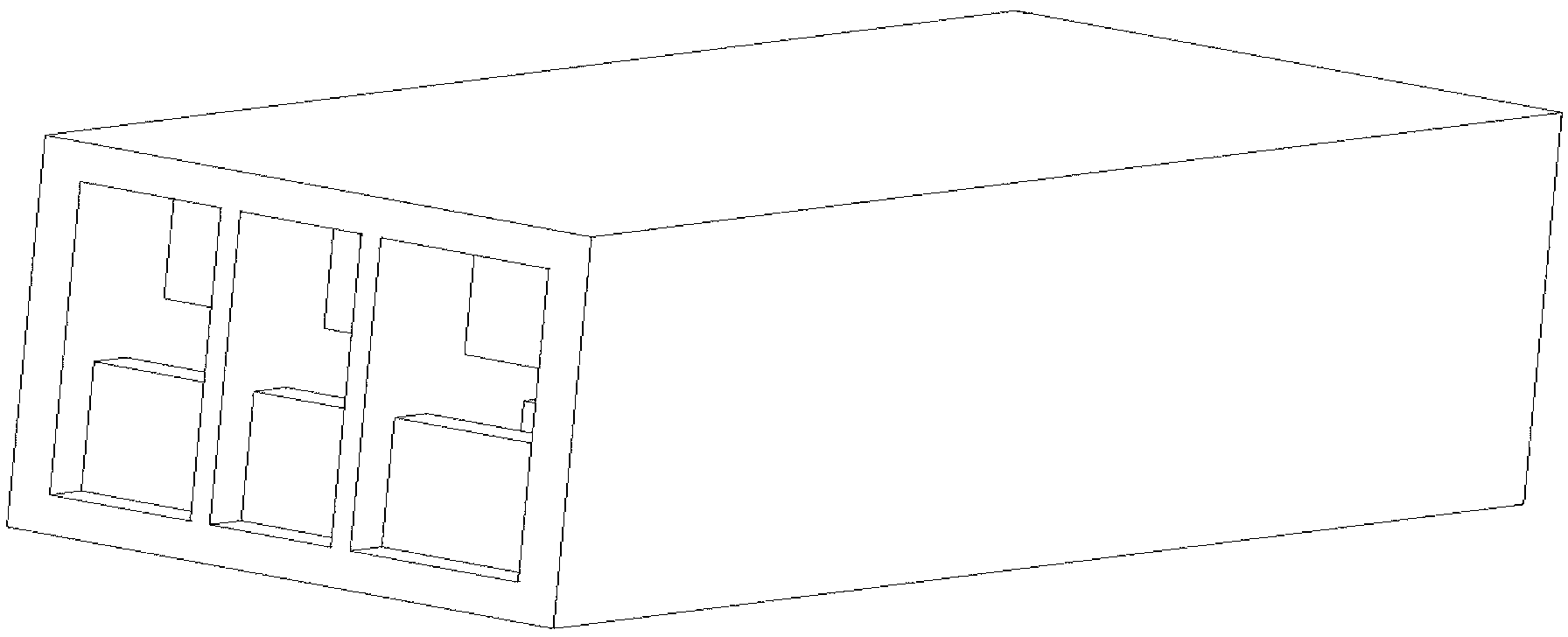

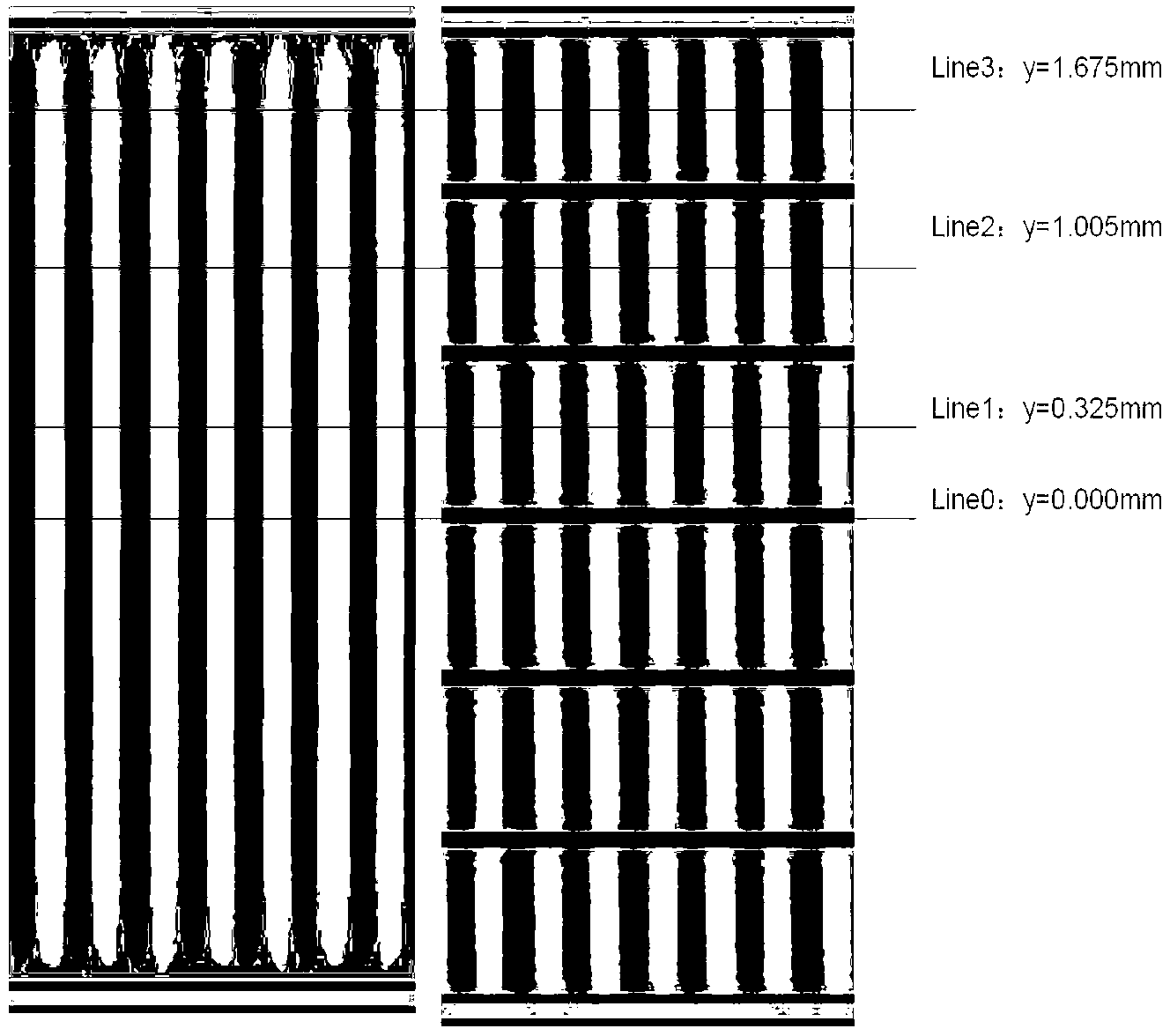

[0026] As shown in Figure 1, a comb-shaped slow-wave structure with multiple strip electron beam channels includes a rectangular waveguide wall 1 with open ends. The inner wall of the lower end of the rectangular waveguide wall 1 is staggered with double rows of comb-shaped teeth 2 , The rectangular waveguide wall 1 is inserted with n inserts 3 at equal intervals; the origin is the lower left corner of the front end of the rectangular waveguide wall 1 with open ends to establish XYZ three-dimensional coordinates, the origin is vertical upward as the Z axis, and the origin horizontal to the left is Y The axis, the origin horizontally and backward is the X axis, each tooth 2 is equally spaced and parallel to the YZ plane, and each insert 3 is parallel to the XZ plane.

[0027] The distance between the upper row of teeth and the lower row of double-row comb-shaped teeth is left as a strip electron injection flight path. The teeth 2 are rectangular, the insert 3 is a metal sheet, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com