a cr 3+ ,mg 2+ ,fe 3+ , f - Co-doped composite lithium-rich cathode material and preparation method thereof

A lithium-rich cathode material and co-doping technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of fast capacity decay, incomplete understanding of the mechanism of action, poor cycle stability, etc., and achieve low reversibility, Effect of reducing irreversible capacity loss and improving cycle capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

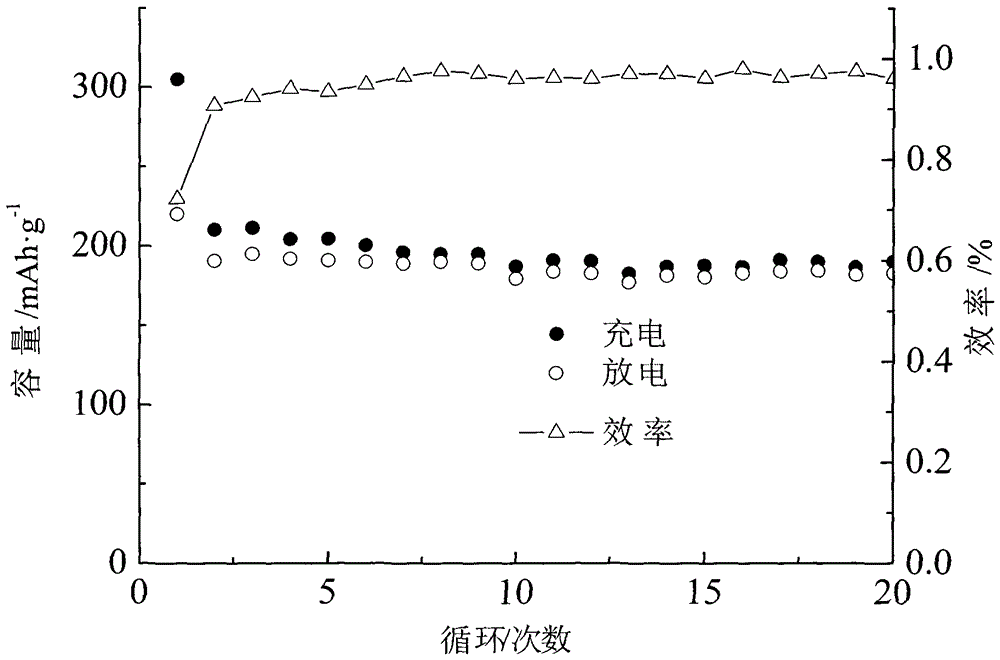

Embodiment 1

[0013] Example 1: LiNO 3 : Mn(CH 3 COO) 2 ·4H 2 O:Ni(CH 3 COO) 2 ·4H 2 O:Mg(NO 3 ) 2 ·6H 2 O:Fe(NO 3 ) 3 ·9H 2 O:Cr(NO 3 ) 3 ·9H 2 O: LiF is 1.091: 0.5365: 0.4365: 0.009: 0.009: 0.009: 0.009 (molar ratio) and mix evenly, add it to deionized water, add tartaric acid whose amount is 1.5 times the total amount of all metal ions, and stir well to Completely dissolved; the temperature of the system was raised to 70°C and stirring was continued until 71% of the water evaporated, at which point the solution gradually became viscous and jelly-like. The jelly-like material was dried in an oven at 130°C for 22 hours and then ground in a mortar for 10 minutes. The obtained powder was heated to 500 °C at a rate of 2 °C / min in a tube furnace and calcined at this temperature for 3 hours. After cooling, the powder was taken out, and the powder was further ground in a mortar for 10 minutes. The powder was pressed with a pressure of 100 MPa. Then, the temperature is raised to 8...

Embodiment 2

[0014] Example 2: LiNO 3 : Mn(CH 3 COO) 2 ·4H 2 O:Ni(CH 3 COO) 2 ·4H 2 O:Mg(NO 3 ) 2 ·6H 2 O:Fe(NO 3 ) 3 ·9H 2 O:Cr(NO 3 ) 3 ·9H 2 O: LiF is 1.465: 0.7125: 0.2125: 0.025: 0.025: 0.025: 0.03 (molar ratio), mix evenly, add it to deionized water, add tartaric acid whose amount is 2.5 times the total amount of all metal ions, and stir well to Completely dissolved; the temperature of the system was raised to 85°C and stirring was continued until 85% of the water evaporated, at which point the solution gradually became viscous and jelly-like. The jelly-like mass was dried in an oven at 200°C for 48 hours and then ground in a mortar for 30 minutes. The obtained powder was heated to 600°C at a rate of 10°C / min in a tube furnace and calcined at this temperature for 5 hours. After cooling, the powder was taken out and ground in a mortar for 30 minutes, and the powder was pressed with a pressure of 300MPa. Then, the temperature is raised to 950°C in a tube furnace at a ra...

Embodiment 3

[0015] Example 3: LiNO 3 : Mn(CH 3 COO) 2 ·4H 2 O:Ni(CH 3 COO) 2 ·4H 2 O:MgCl 2 ·6H 2 O:Fe(NO 3 ) 3 ·9H 2 O:Cr(NO 3 ) 3 ·9H 2 O: LiF is 1.168: 0.576: 0.376: 0.016: 0.016: 0.016: 0.024 (molar ratio) and mix evenly, add it to deionized water, and add tartaric acid whose amount is 2.0 times the total amount of all metal ions and stir well to Completely dissolved; the temperature of the system was raised to 78°C and stirring was continued until 78% of the water evaporated, at which point the solution gradually became viscous and jelly-like. The jelly-like material was dried in an oven at 170°C for 35 hours and then ground in a mortar for 20 minutes. The obtained powder was heated to 550 °C at a rate of 7 °C / min in a tube furnace and calcined at this temperature for 4 hours. After cooling, the powder was taken out, and the powder was further ground in a mortar for 20 minutes. The powder was pressed with a pressure of 200 MPa. Then, the temperature is raised to 900°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com