Quick support composite insulator hardware for insulated overhead line and operation method of quick support composite insulator hardware

A composite insulator and overhead insulation technology, which is applied in the direction of overhead line/cable equipment, overhead installation, electrical components, etc., can solve problems such as hidden dangers of normal operation of lines, rust and corrosion damage of pressure plate screws, technical level impact, etc., and achieve fixed operation quality Good, increase the construction speed, improve the effect of safe operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

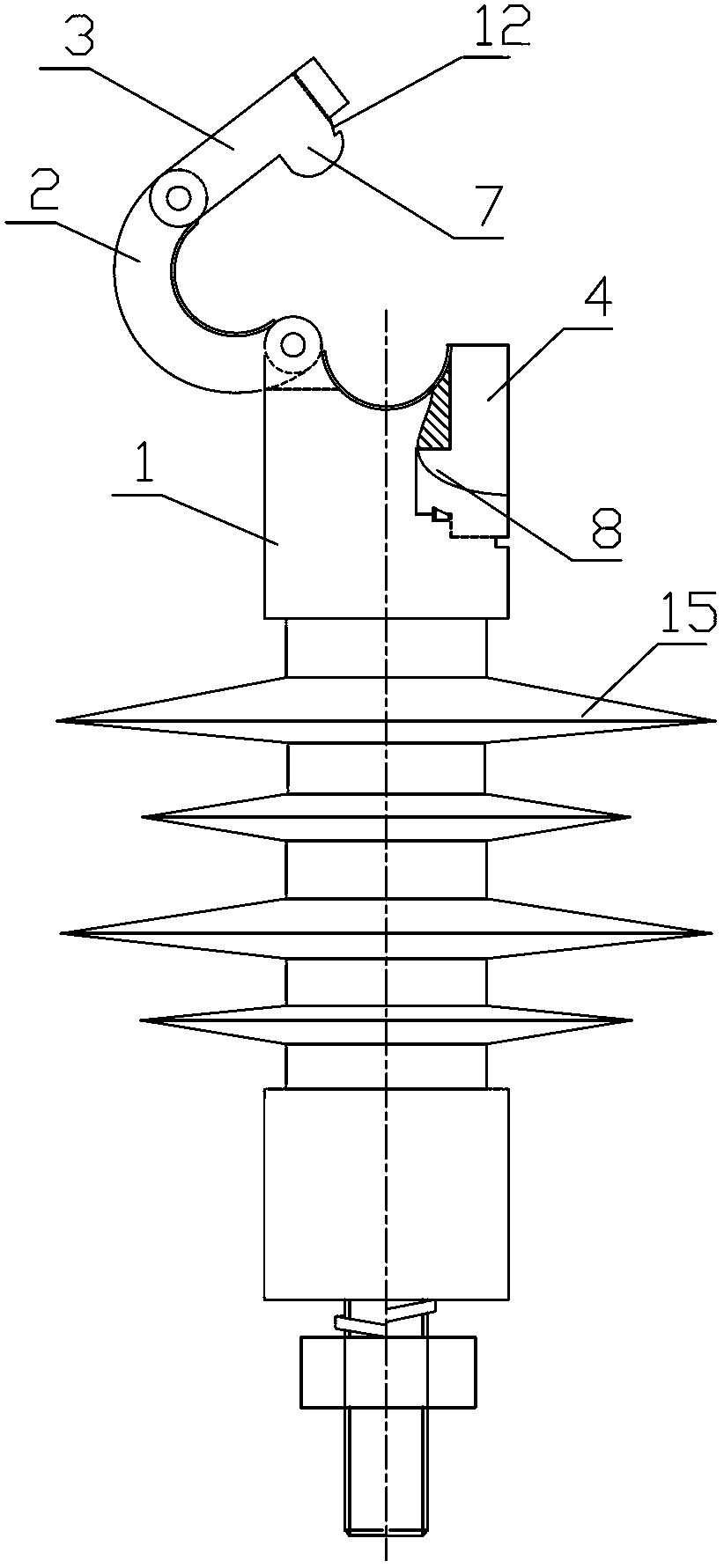

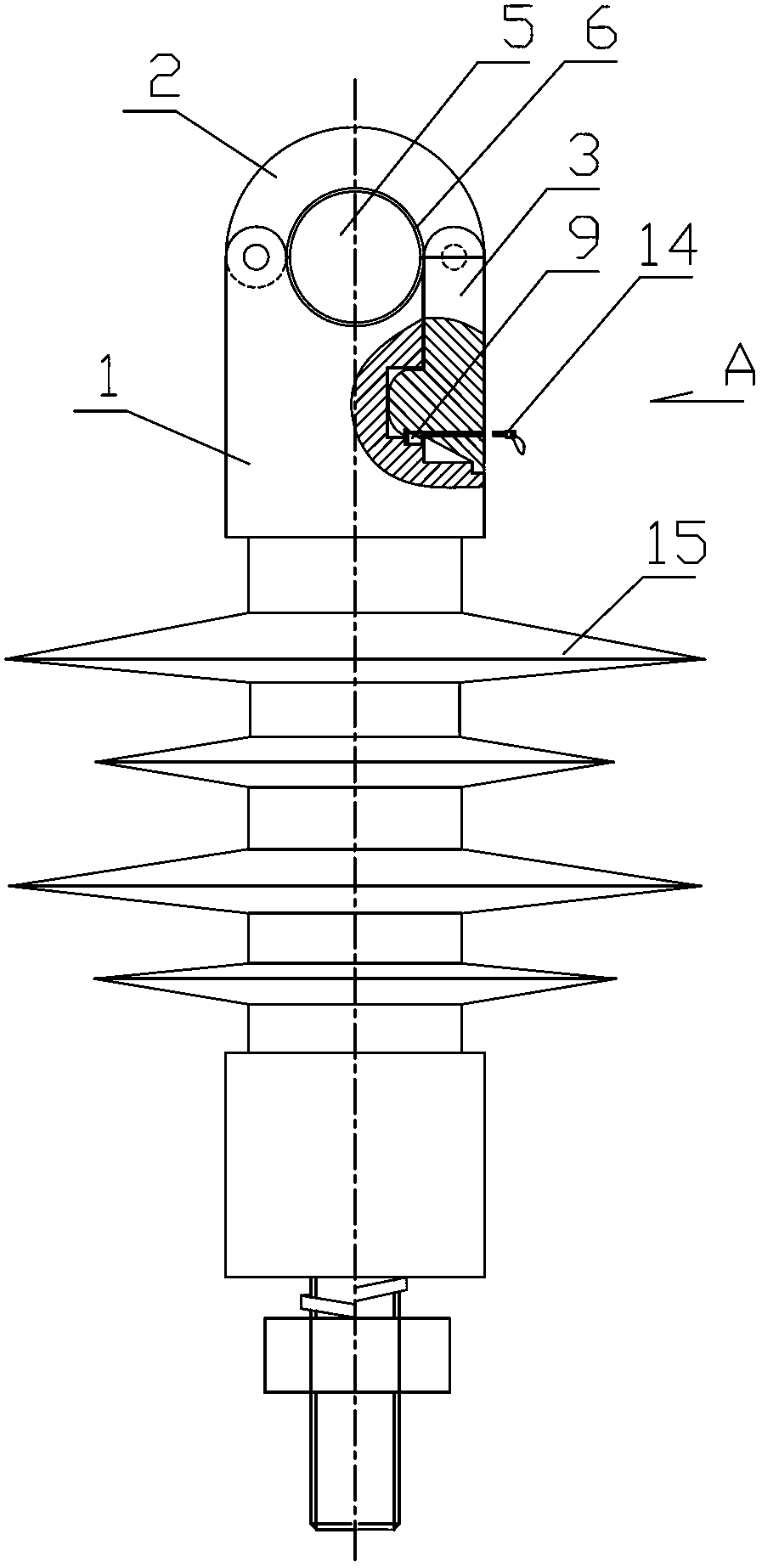

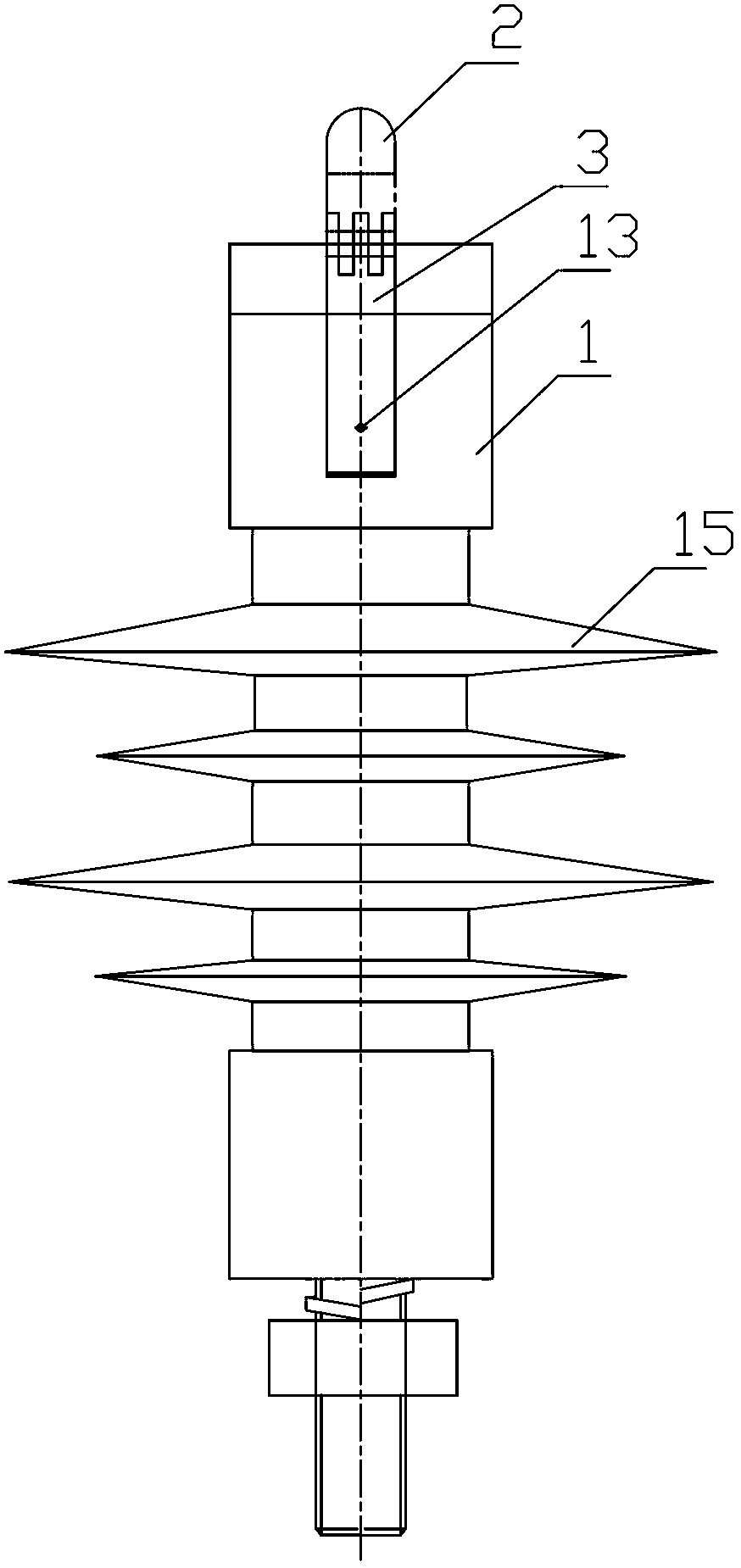

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0027] See Figure 1 to Figure 5 , is a structural schematic diagram of an embodiment of a quick support composite insulator fitting for overhead insulated wires in the present invention. The top of the metal body 1 is provided with an arc-shaped pressing plate 2, one end of the arc-shaped pressing plate 2 is hinged to one side of the metal body 1, and the arc-shaped pressing plate 2 The other end is hinged with one end of the spring lock 3, and the other side of the metal body 1 is provided with a lock groove 4 corresponding to the spring lock. When the arc-shaped pressing plate 2 is in the locked state, the arc-shaped pressing plate 2 and the top of the metal body 1 are combined into a wire and fixed The hole 5 and the size of the wire fixing hole 5 match the specifications of the overhead insulated wire. The inner wall of the wire fixing hole 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com