Turbine blade for a gas turbine

A technology for turbine blades and gas turbines, applied in the directions of blade support elements, mechanical equipment, engine elements, etc., can solve problems such as unusable casting cores, and achieve the effects of reducing scrap rate, improving production time, and improving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Identical features are provided with the same reference numerals throughout the figures.

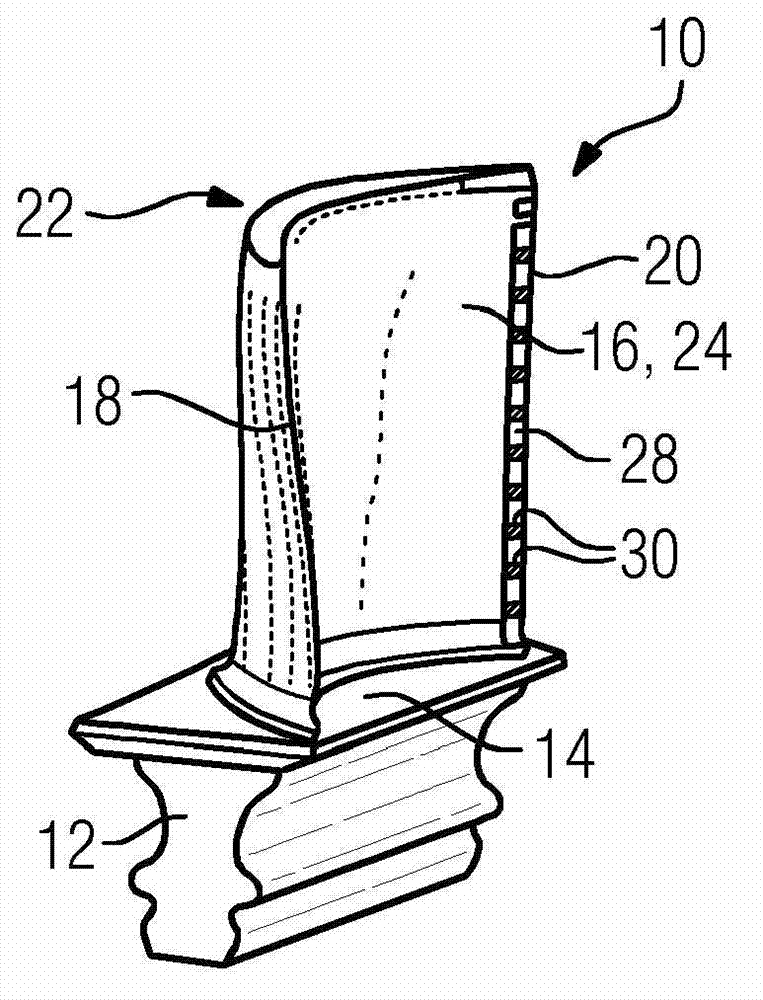

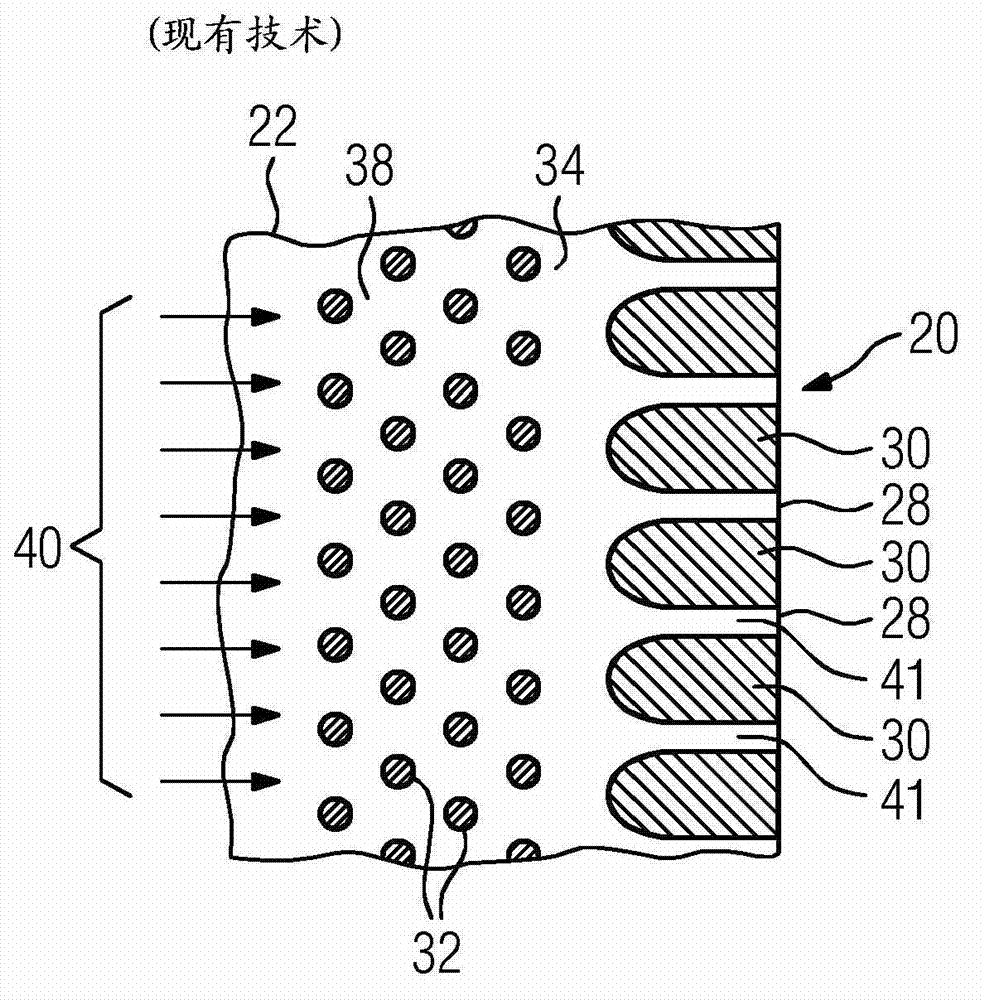

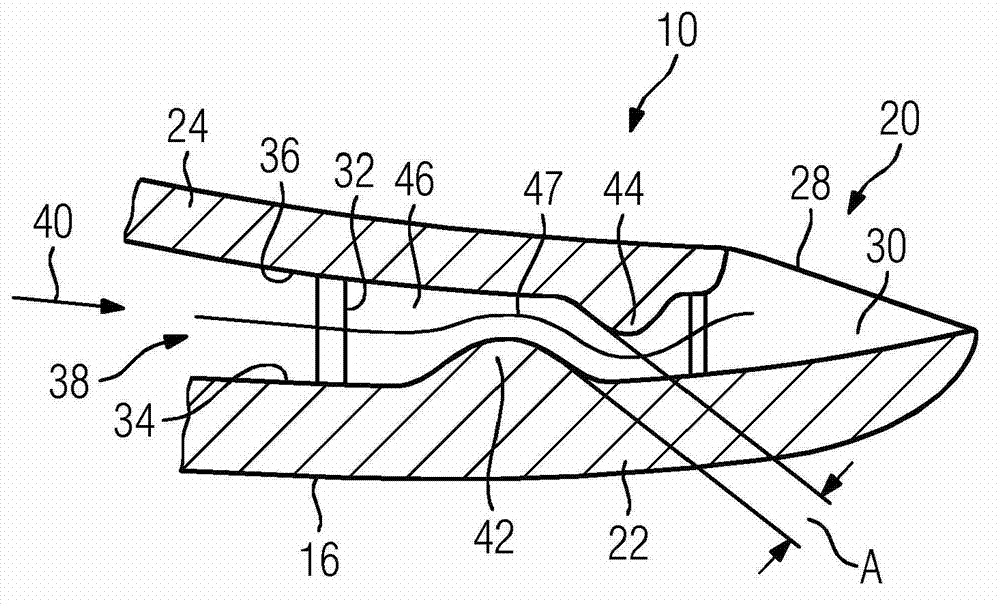

[0030] exist figure 1 A perspective view of a gas turbine blade 10 according to the present invention is shown in . Gas Turbine Blades 10 According to figure 1 are formed as rotor blades. The invention can also be used in guide vanes (not shown) of gas turbines. The turbine blade 10 comprises a fir-tree-shaped blade root 12 in cross-section and a platform 14 arranged thereon. Attached to the platform 14 is a streamlined curved airfoil 16 having a leading edge 18 and a trailing edge 20 . Cooling openings arranged as so-called “spoutheads” are provided on the leading edge 18 , out of which cooling medium flowing inside, preferably cooling air, can flow out. Leaf Body 16 Includes - About figure 1- The suction side wall 22 on the rear side and the pressure side wall 24 on the front side. A plurality of openings 28 are provided along the rear edge 20 , which are separated from o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com