Optical diffraction element and endoscope

A diffractive optical element and endoscope technology, which is applied in the field of diffractive optical elements and endoscopes, can solve the problems of high cost, insufficient mass production, and easy warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

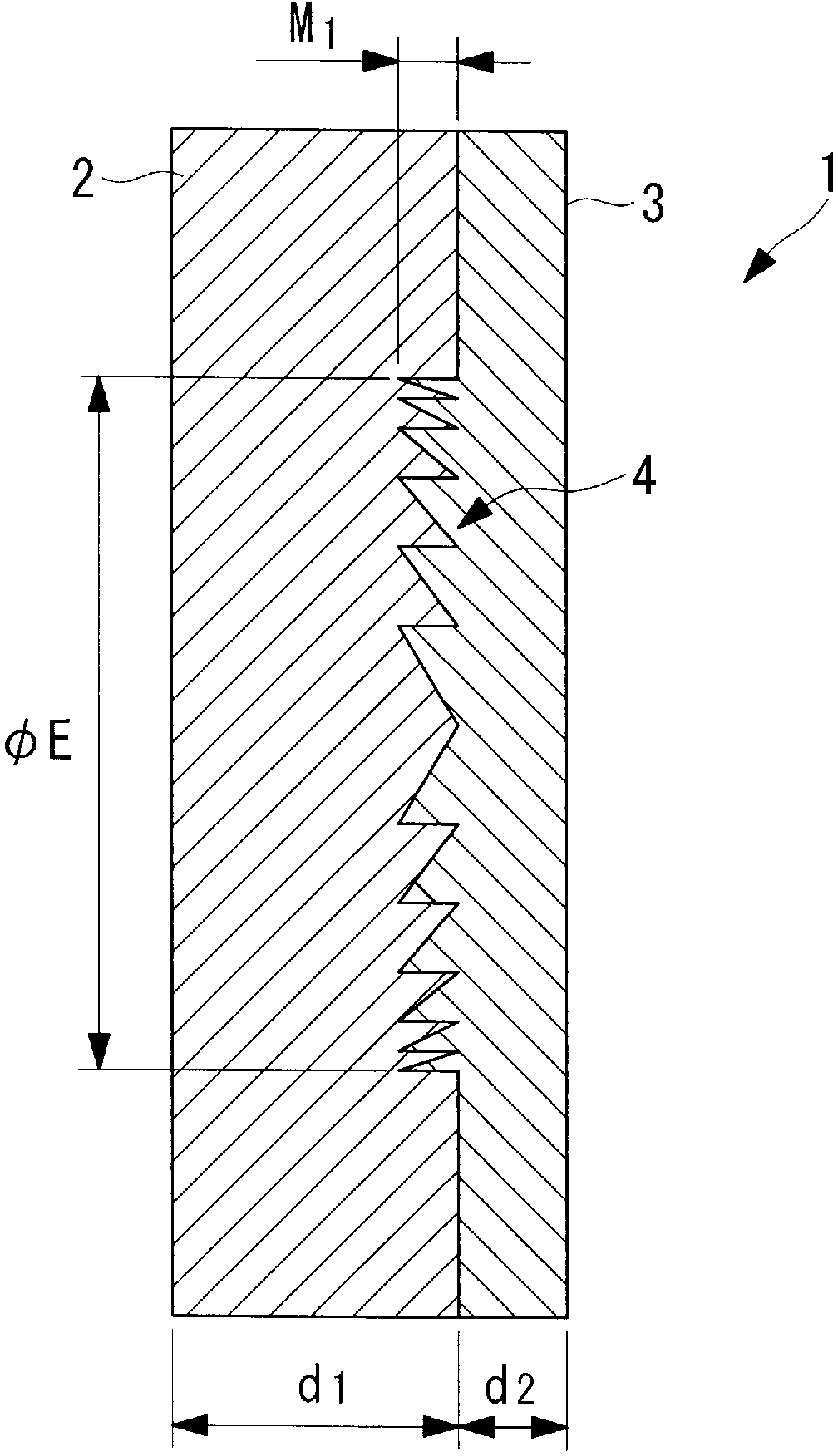

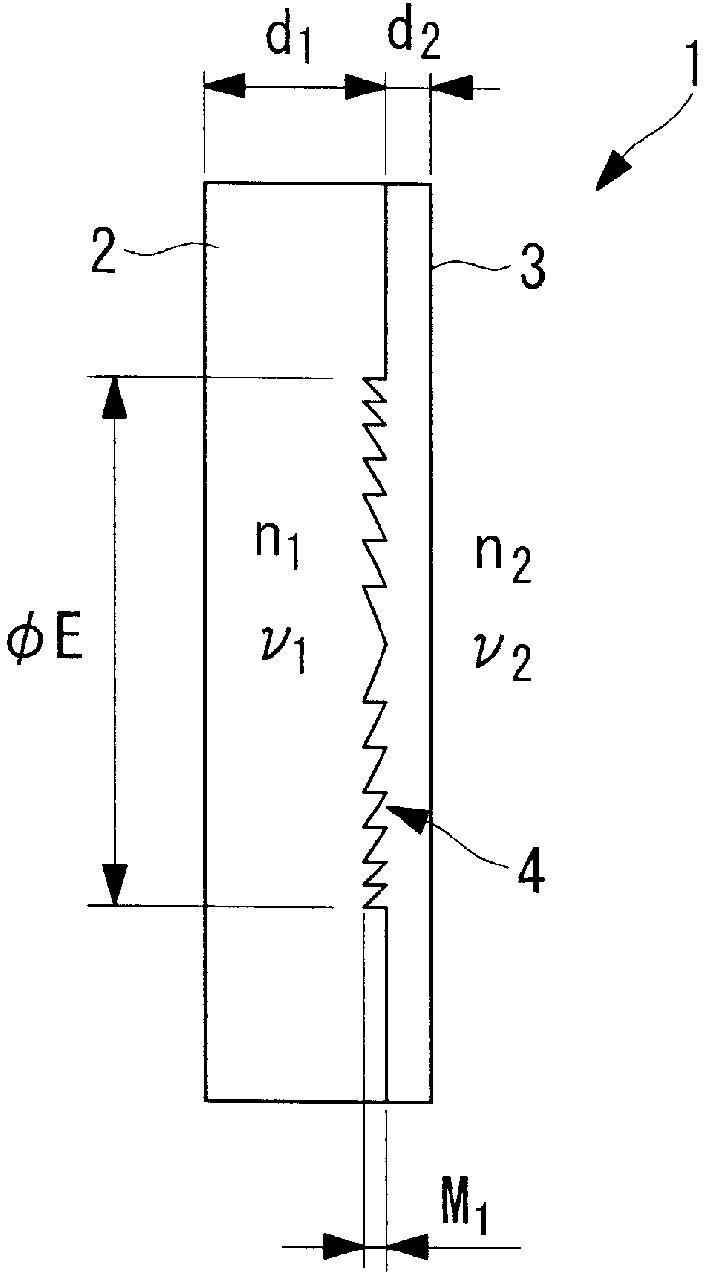

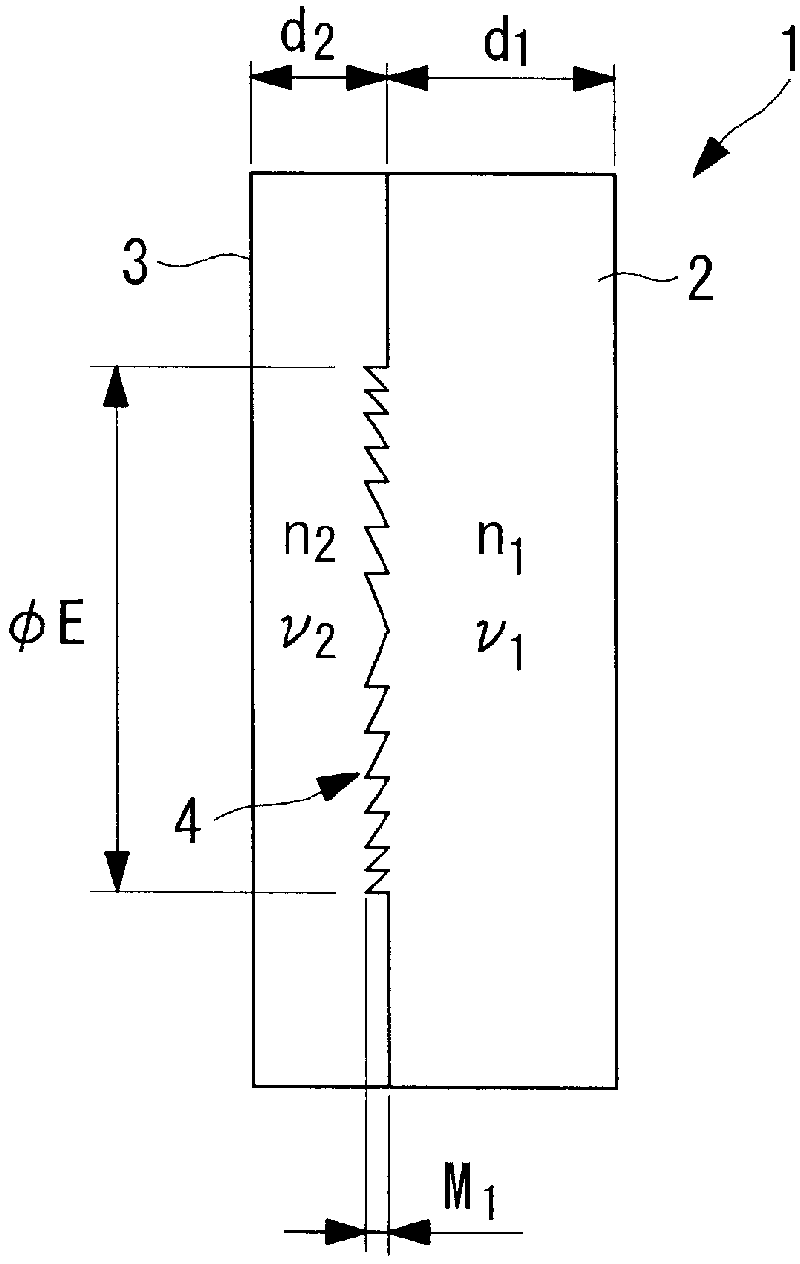

[0088] Hereinafter, a diffractive optical element according to an embodiment of the present invention will be described with reference to the drawings.

[0089] like figure 1 As shown, the diffractive optical element 1 of this embodiment is a multilayer diffractive optical element 1 in which the first optical material layer 2 and the second optical material layer 3 are laminated.

[0090] The two optical material layers 2, 3 are respectively composed of different energy curable resins.

[0091] The first optical material layer 2 is the first cured optical material layer, with a central thickness of d 1 , the refractive index in the d-line is n 1 , the Abbe number is ν 1 . The second optical material layer 3 is a post-cured optical material layer with a central thickness of d 2 , the refractive index in the d-line is n 2 , the Abbe number is ν 2 .

[0092] In addition, a relief pattern 4 is formed on the interface between the first optical material layer 2 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com