Electric seedling raising stand

A kind of seedling raising frame and electric technology, which is applied in the field of seedling raising, can solve the problems of slow growth, lack of sufficient sunlight for the lower seedling raising bed frame, and inability to grow, so as to achieve the effect of increasing the utilization rate, reducing the cost of seedling raising, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

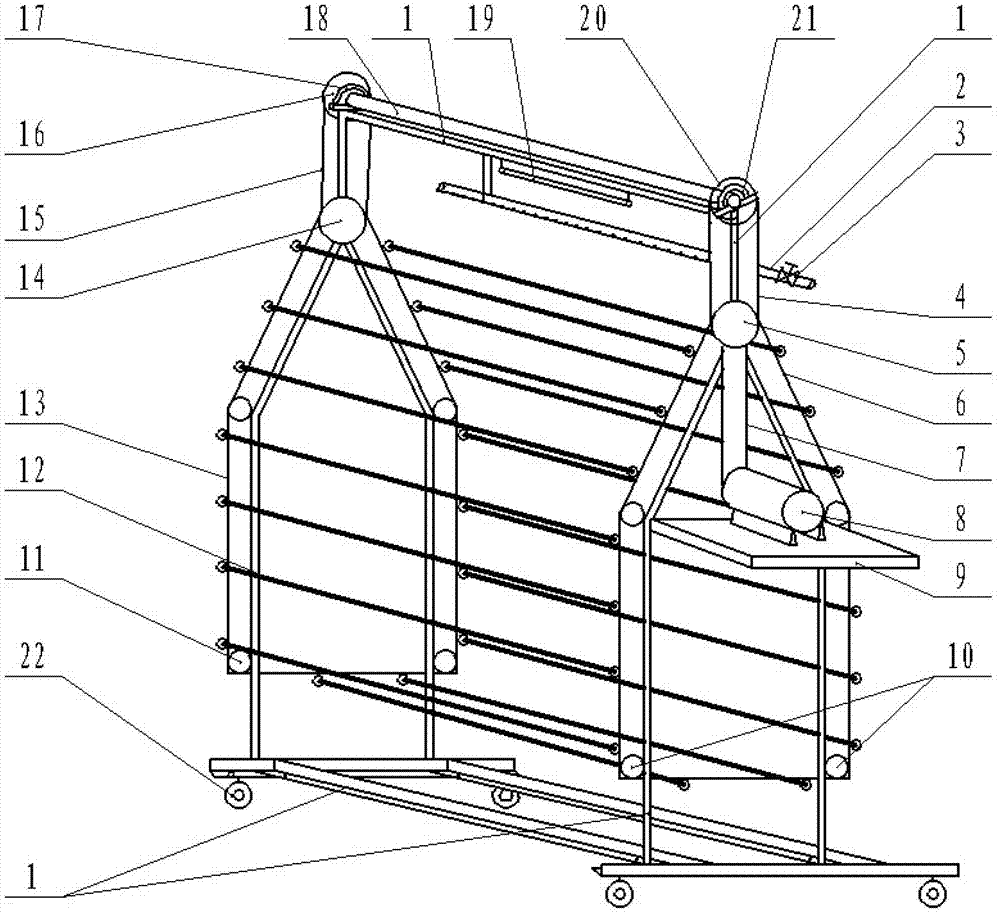

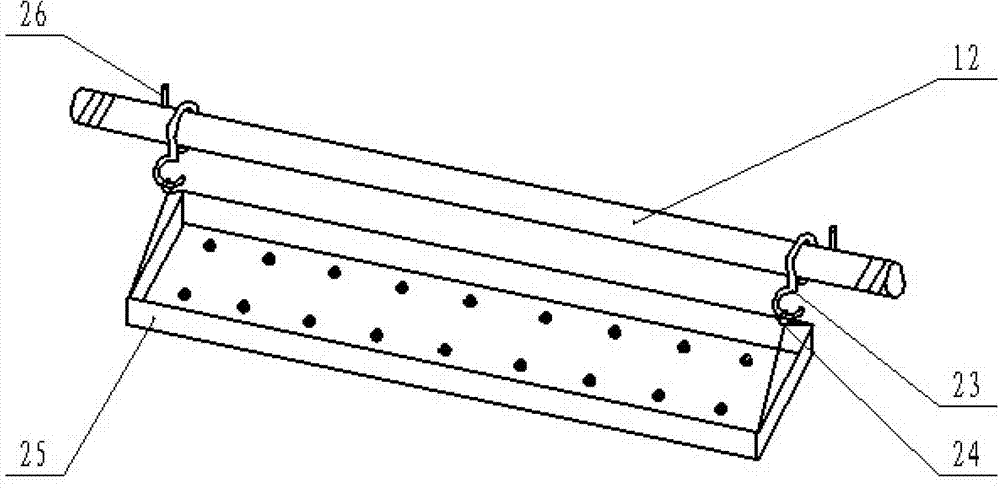

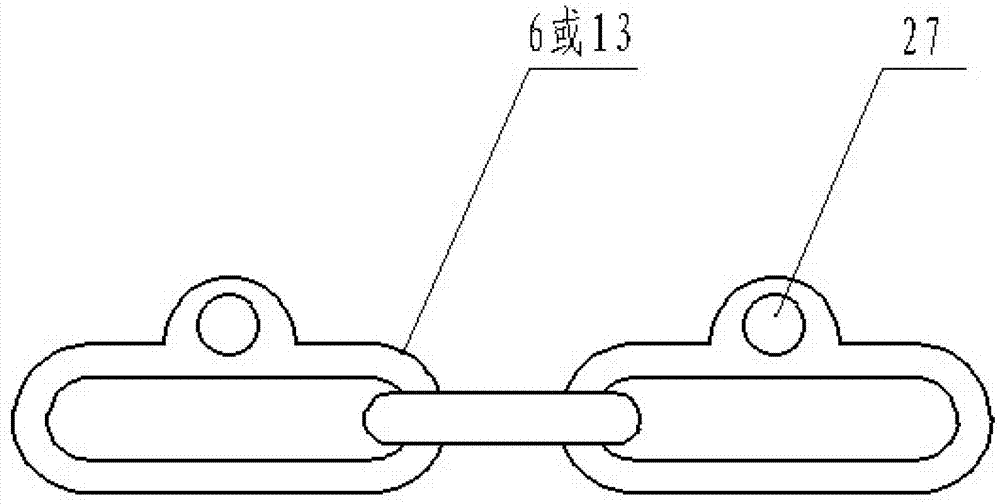

[0025] An electric seedling raising frame, mainly comprising a frame 1, a motor 8 and a hanging rod 12, one side of the frame 1 is provided with a supporting frame 9, and the motor 8 is fixed on the supporting frame 9; driving wheels A5 are respectively arranged on both sides of the frame 8 , the driven wheel A10, the driving wheel B14 and the driven wheel B11; the motor 8 is connected with the driving wheel A5 through the drive gear belt 7; the two sides of the frame 1 are respectively provided with the conveying chain A6 and the conveying chain B13; Wheel A20 and driving wheel B16; driving wheel A20 and driving wheel B16 are respectively connected to driving wheel A5 and driving wheel B14 through synchronous belt A4 and synchronous belt B15; between driving wheel A20 and driving wheel B16 is set on the bearing through the top of frame 1 The transmission shaft 18 of seat A21 and bearing seat B17 is connected; Hanging rod 12 two ends are respectively fixed on the conveyor chain...

Embodiment 2

[0028] An electric seedling raising frame, mainly comprising a frame 1, a motor 8 and a hanging rod 12, one side of the frame 1 is provided with a support frame 9, and the motor 8 is fixed on the support frame 9; the two sides of the frame 1 are respectively provided with driving wheels A5 , the driven wheel A10, the driving wheel B14 and the driven wheel B11; the motor 8 is connected with the driving wheel A5 through the drive gear belt 7; the two sides of the frame 1 are respectively provided with the conveying chain A6 and the conveying chain B13; Wheel A20 and driving wheel B16; driving wheel A20 and driving wheel B16 are respectively connected with driving wheel A5 and driving wheel B14 through synchronous belt A4 and synchronous belt B15; driving wheel A5 is connected with driving wheel A20 above the frame 1, and driving wheel A20 and the drive wheel B16 are connected by the transmission shaft 18 that is arranged on the bearing seat A21 and the bearing seat B17 at the top...

Embodiment 3

[0031] An electric seedling raising frame, mainly comprising a frame 1, a motor 8 and a hanging rod 12, one side of the frame 1 is provided with a support frame 9, and the motor 8 is fixed on the support frame 9; the two sides of the frame 1 are respectively provided with driving wheels A5 , the driven wheel A10, the driving wheel B14 and the driven wheel B11; the motor 8 is connected with the driving wheel A5 through the drive gear belt 7; the two sides of the frame 1 are respectively provided with the conveying chain A6 and the conveying chain B13; Wheel A20 and driving wheel B16; driving wheel A20 and driving wheel B16 are respectively connected to driving wheel A5 and driving wheel B14 through synchronous belt A4 and synchronous belt B15; between driving wheel A20 and driving wheel B16 is set on the bearing through the top of frame 1 The transmission shaft 18 of seat A21 and bearing seat B17 is connected; Hanging rod 12 two ends are respectively fixed on the conveyor chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com