Double-oxidization catalyst for purifying diesel engine exhaust and preparation method thereof

A technology for exhaust gas purification and double oxidation, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Problems such as limited capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

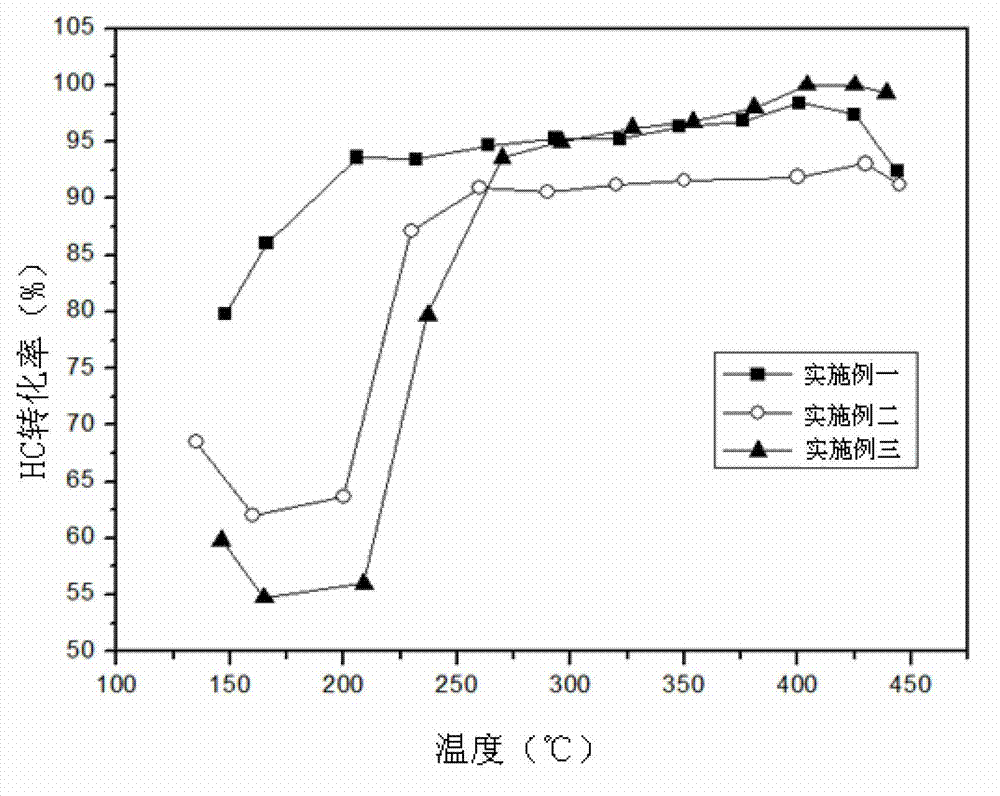

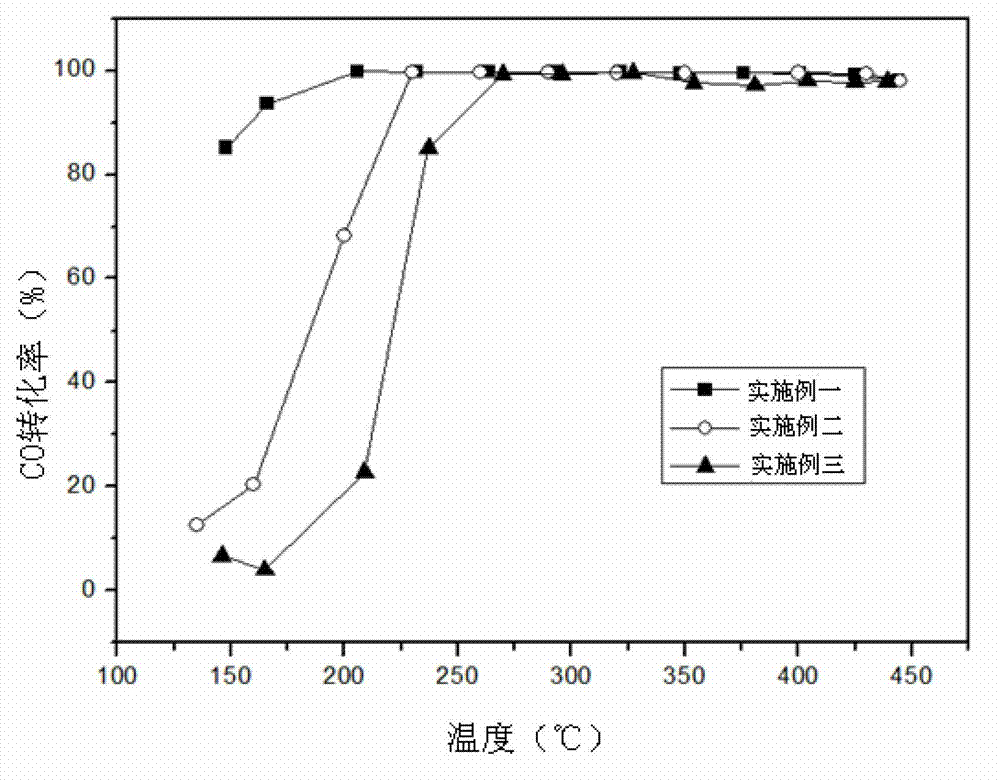

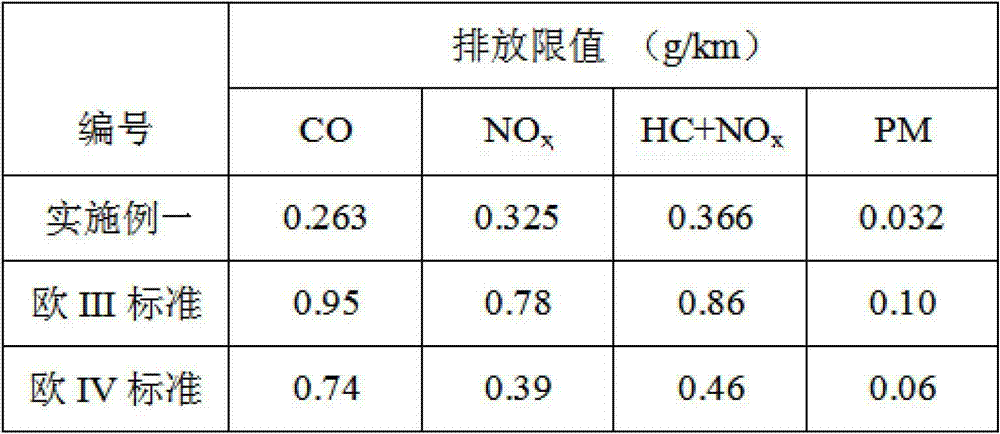

Embodiment 1

[0021]A double oxidation catalyst for purifying diesel vehicle exhaust, comprising a front-stage carrier and a rear-stage carrier arranged in sequence along the axial direction of an engine exhaust port, the front-stage carrier is arranged close to the engine exhaust port, and the rear-stage carrier is far away from the engine The exhaust port is set, the front-stage carrier is coated with the front-stage coating, and the rear-stage carrier is coated with the rear-stage coating, which is used to prepare the slurry for the front-stage coating and the rear-stage coating. Contains deionized water, rare earth composite oxide, modified alumina, binder and active components, and at least one of the two slurries used to prepare the pre-coat and post-coat also contains Si-alumina composite oxide.

[0022] The slurry used to prepare the pre-coating contains deionized water, rare earth composite oxide and modified alumina, and its mass ratio is 1:0.2~0.6:0.3~0.5, which is used to prepar...

Embodiment 2

[0025] The difference from Example 1 is that the slurry used to prepare the front-level coating contains deionized water, rare earth composite oxide, modified alumina and silicon-aluminum composite oxide, and its mass ratio is 1:0.2~0.6: 0.3-0.5:0.6-0.7, the slurry used to prepare the back-stage coating contains deionized water, rare earth composite oxide and modified alumina, and the mass ratio thereof is 1:0.04-0.06:0.1-0.2.

Embodiment 3

[0027] The difference with Embodiment 1 and Embodiment 2 is that the slurry used to prepare the front-level coating contains deionized water, rare earth composite oxides, modified alumina and silicon-aluminum composite oxides, and its mass ratio is 1: 0.2~0.6:0.3~0.5:0.6~0.7, the slurry used to prepare the back-level coating contains deionized water, rare earth composite oxide, modified alumina and silicon-aluminum composite oxide, and its mass ratio is 1: 0.04~0.06:0.1~0.2:0.15~0.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com