Preparation method of high grade copper oxide concentrate

A copper oxide medium ore and copper oxide technology, which is applied in the field of preparation of high-grade copper oxide concentrate, can solve the problems of low copper grade, high content of impurities in gangue minerals such as calcium and magnesium, and achieve reduction of electric energy, increase of smelting recovery rate, Effects with a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

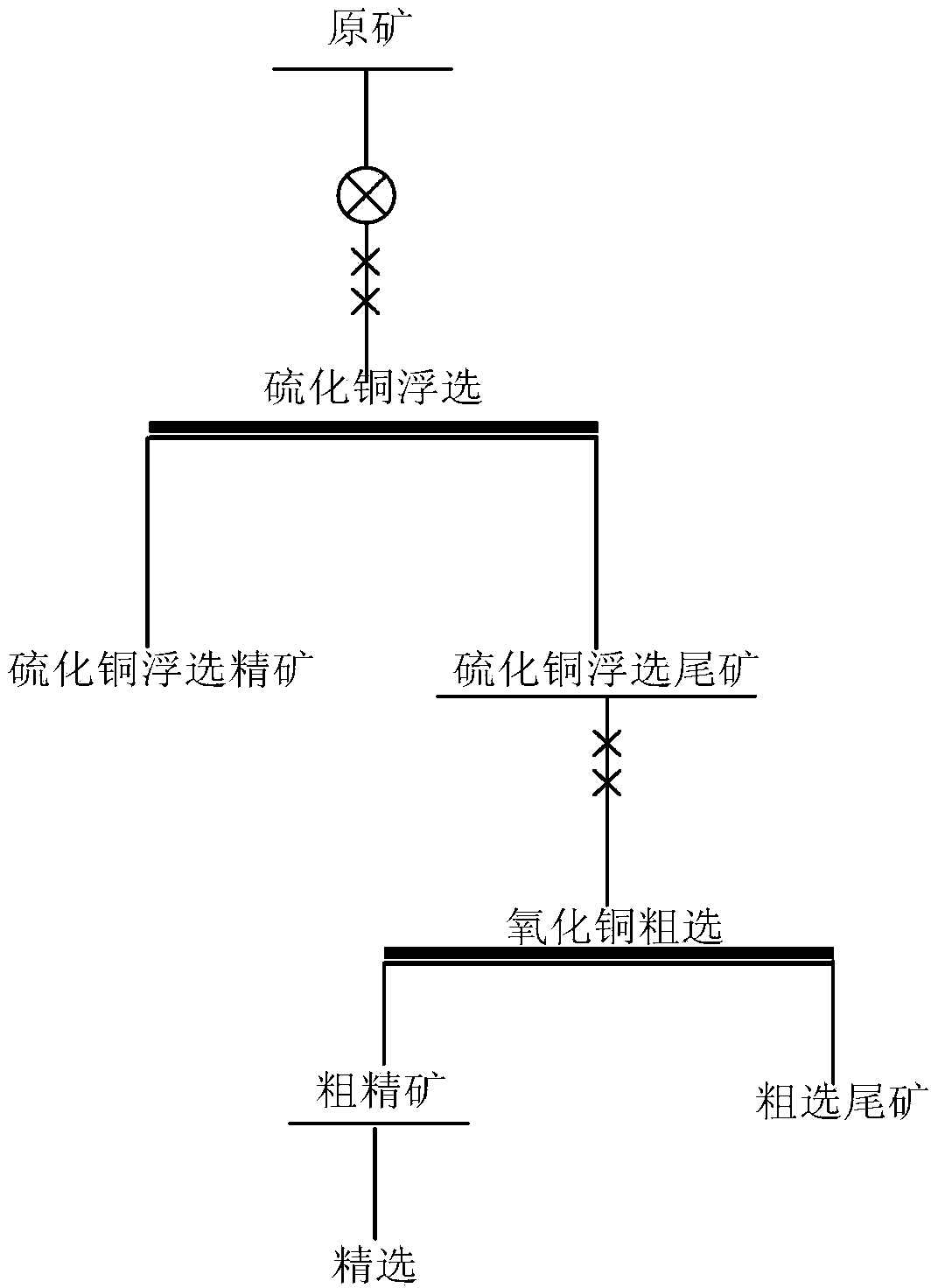

[0024] According to a typical implementation of the present invention, the preparation method of the high-grade copper oxide concentrate is as follows: figure 1 As shown, it includes complex copper oxide raw ore grinding, copper sulfide flotation and copper oxide flotation, wherein copper oxide flotation includes roughing and concentration, roughing includes copper sulfide flotation tailings obtained from copper sulfide flotation Add flotation reagents to the crude concentrate, mix, stir, and separate to obtain rough concentrate and rougher tailings; and beneficiation includes adding gangue mineral inhibitors to the rough concentrate for stirring. sodium sulfonate.

[0025] The present invention adopts processes such as complex copper oxide raw ore grinding, copper sulfide flotation and copper oxide flotation, and carries out copper oxide flotation by adding flotation reagents to copper sulfide flotation tailings. Under the action of flotation agents, it adheres to the foam a...

Embodiment 1

[0046] Copper sulfide flotation tailings, containing 3.26% copper.

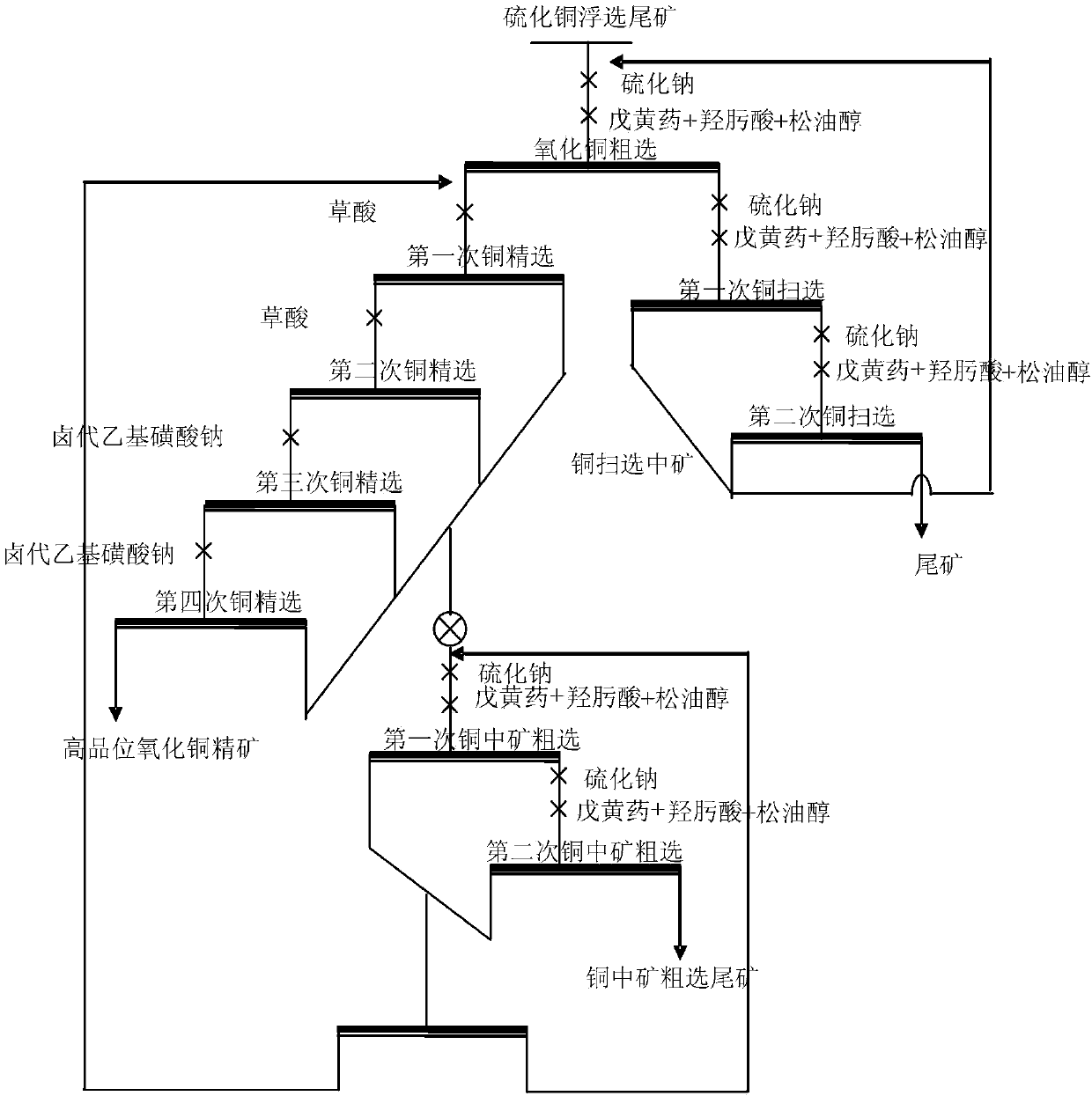

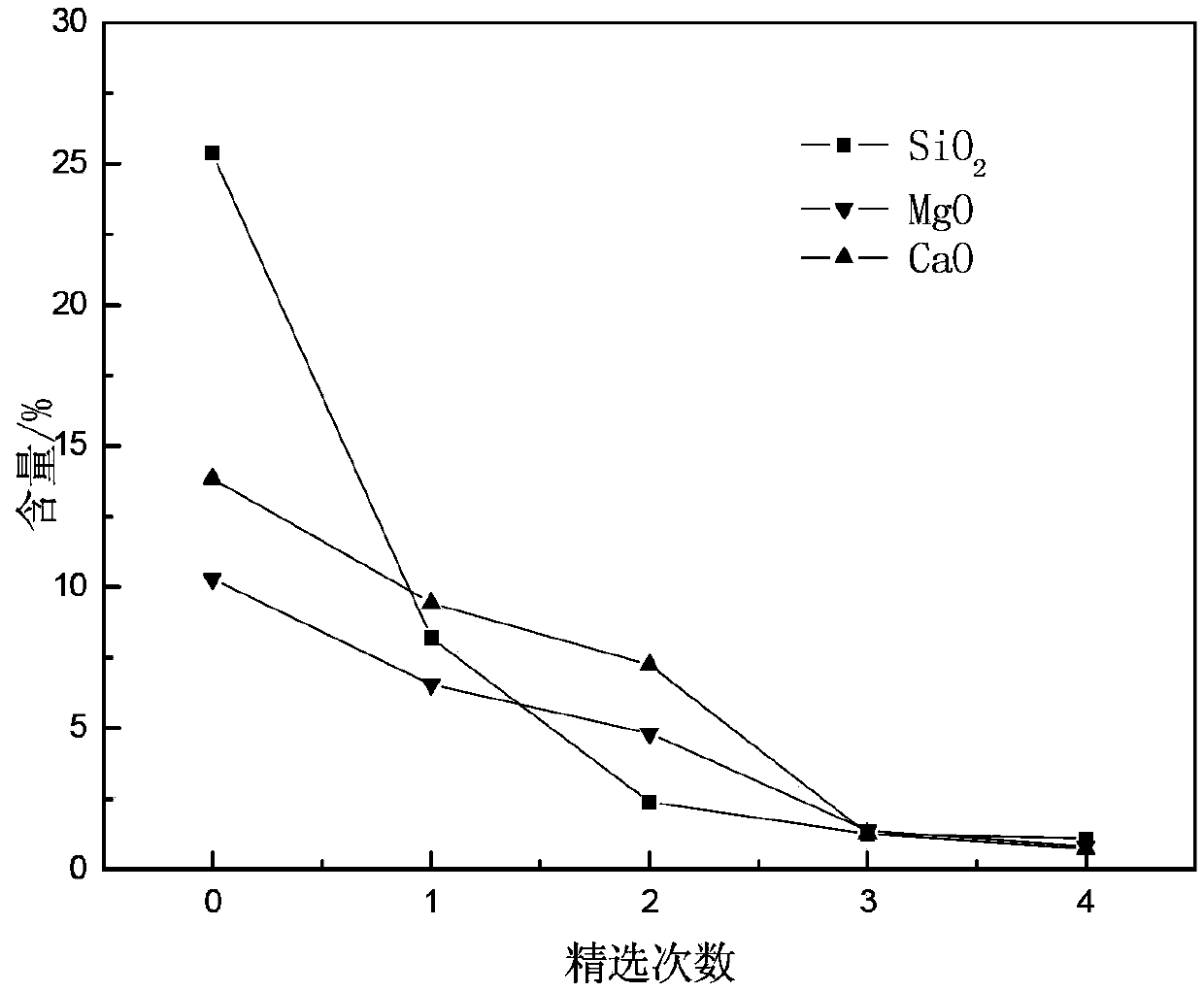

[0047] Copper sulfide flotation tailings roughing: put 1 ton of copper sulfide flotation tailings slurry into the flotation tank for roughing, add 500g sodium sulfide, 80g pentaxanthate, 50g hydroxamic acid and 30g pine Alcohol oil, to obtain copper oxide roughing tailings and foamy copper oxide rough concentrate floating on it; to obtain copper oxide rough concentrate, the copper grade in copper oxide rough concentrate is 11.86%, SiO 2 The content of MgO is 25.36%, the content of MgO is 10.29%, and the content of CaO is 13.84%.

[0048] Four times of beneficiation of rough concentrate: add 60g of oxalic acid as an inhibitor to the foamy rough concentrate while stirring, and carry out copper beneficiation operation; obtain the first concentrate ore and the first middle ore. While stirring, add 30g of oxalic acid to the first concentration ore to carry out the second copper concentration operation to obtain t...

Embodiment 2

[0054] Copper sulfide flotation tailings, containing 1.42% copper. The process difference with embodiment 1 is:

[0055] Add 800g of sodium sulfide, 120g of pentaxanthate, 80g of hydroxamic acid and 50g of terpineol oil during roughing of copper sulfide flotation tailings. 2 The content of MgO is 30.44%, the content of MgO is 8.91%, and the content of CaO is 11.86%.

[0056] Four times of beneficiation of rough concentrate: add 150g of oxalic acid in the first beneficiation operation; add 75g of oxalic acid in the second beneficiation step; Sodium bromoethyl sulfonate, and finally get high-grade copper concentrate and selected No. 4 middle ore.

[0057] The high-grade copper oxide concentrate has a recovery rate of 71.25%, grading 50.76% copper, SiO 2 The content of CaO is 1.02%, the content of CaO is 0.76%, and the content of MgO is 0.91%.

[0058] SiO in blister copper ore, copper concentrate 1 concentrate, copper concentrate 2 concentrate, copper concentrate 3 concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com