Quenching machine for rapid heat treatment

A technology of rapid heat treatment and quenching machine, applied in the field of heat treatment, can solve the problems of scrapped workpieces, forgotten time, low efficiency, etc., and achieve the effects of high production efficiency, automatic time control, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

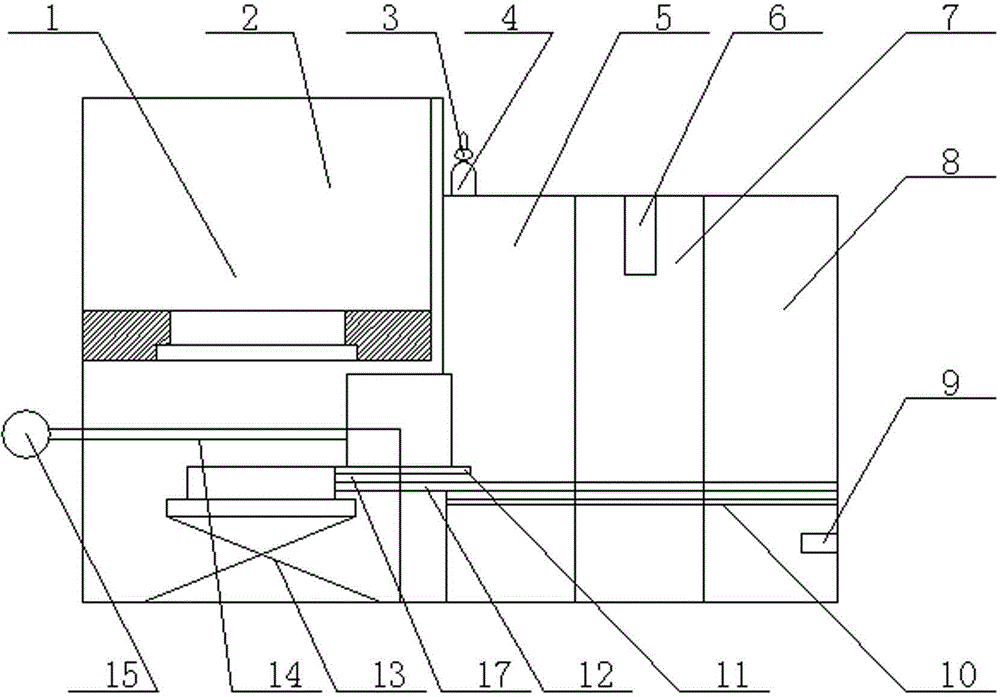

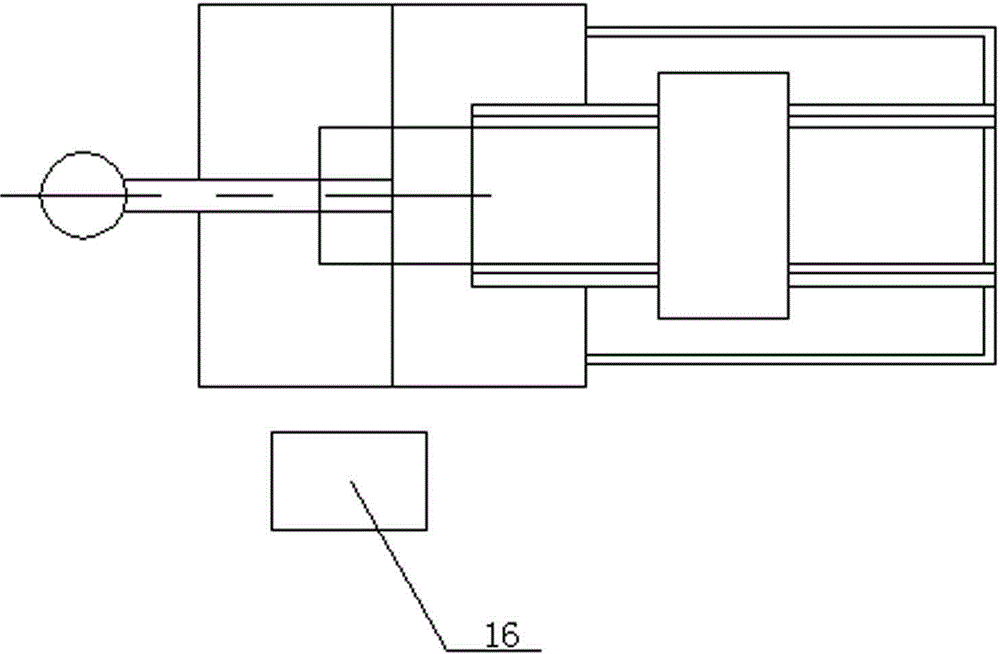

[0008] see Figure 1-2 , the specific embodiment adopts the following technical solutions: it includes a body 1, a heating device 2, a furnace door lifter 3, a fan 4, an air-cooled quenching bin 5, a water cooling device 6, a water-cooled quenching bin 7, an air-cooled quenching bin 8, an exhaust System 9, trolley track 10, trolley 11, transmission system 12, lifting frame system 13, feeding device 14, feeding device 15, electric control device 16, optional device 17; heating device 2 is arranged on the upper left corner of body 1, wind The cold quenching bin 5 is arranged on the right side of the heating device 2, the fan 4 is arranged on the left upper part of the air-cooled quenching bin 5, the furnace door lifter 3 is arranged on the top of the fan 4, and the water-cooled quenching bin 7 is arranged on the top of the air-cooled quenching bin 5. On the right side, the water cooling device 6 is arranged on the inner upper part of the water-cooled quenching chamber 7, the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com