Composite cast lightweight concrete structure

A lightweight concrete and foam concrete technology, applied in building components, building structures, buildings, etc., can solve the problems of many hidden dangers in building safety, reduced wall use area, poor integrity, etc., to improve building safety and increase earthquake resistance. , the effect of reducing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

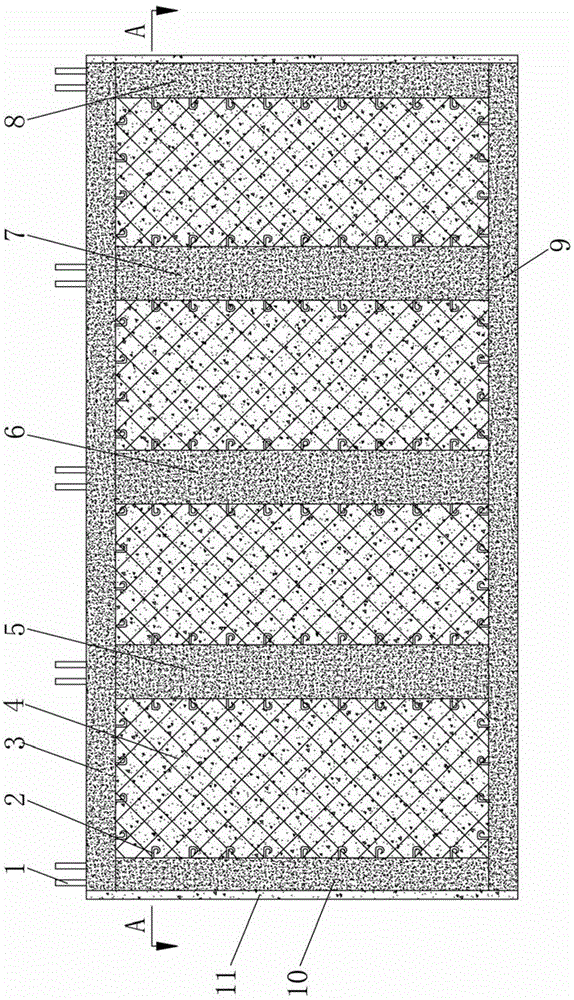

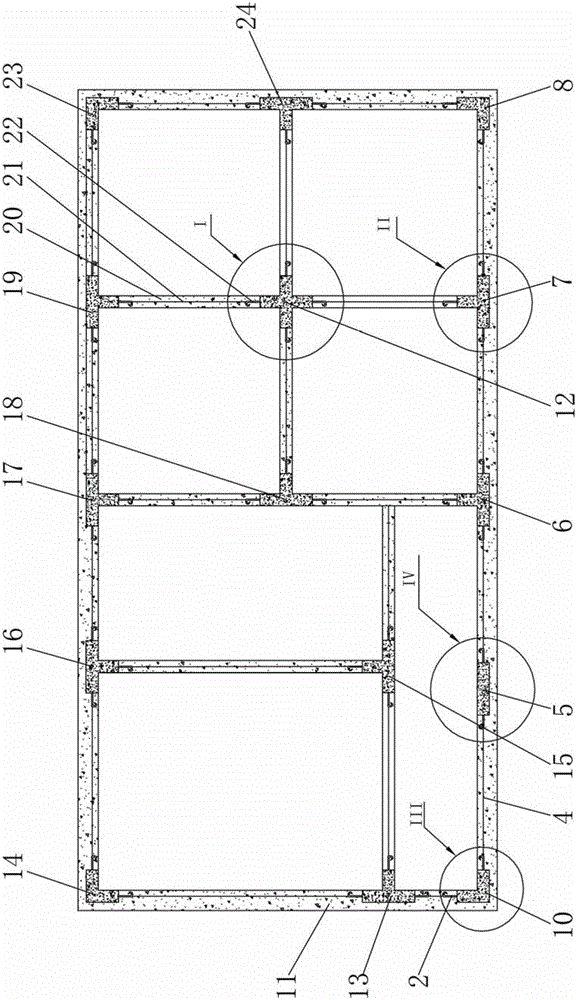

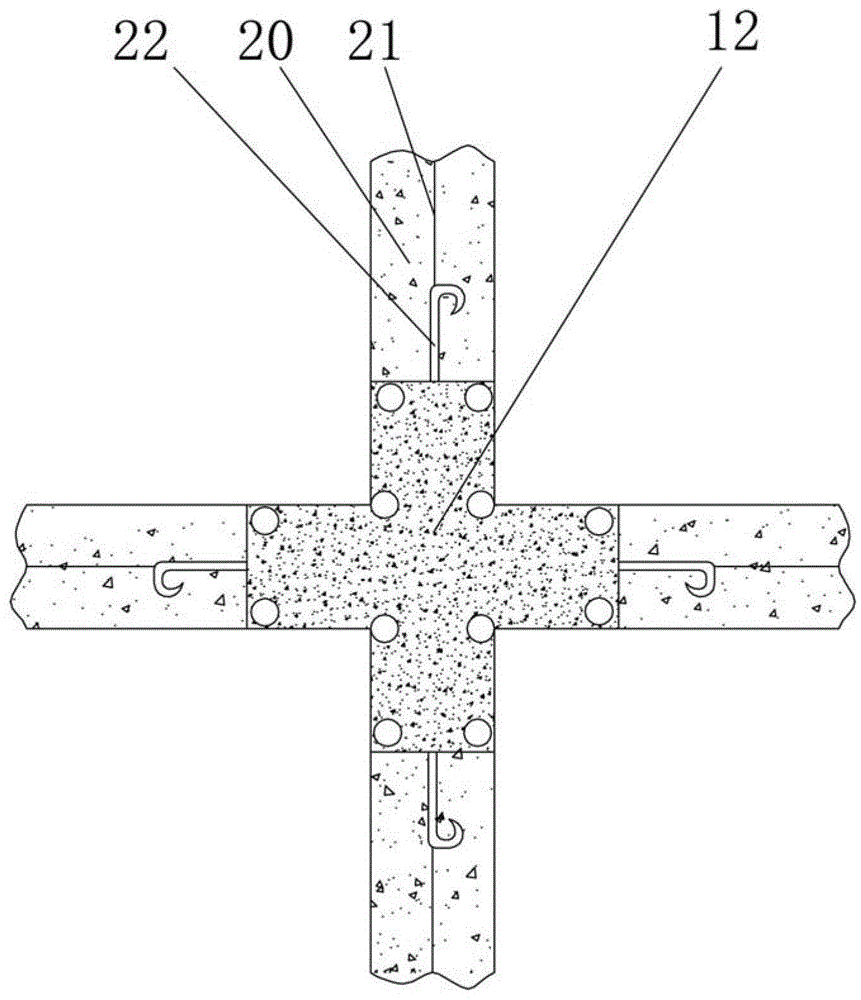

[0016] The specific embodiment of the present invention is, with reference to figure 1 , figure 2 , taking the first floor of a two-story building as an example, it includes reinforced concrete columns, reinforced concrete beams, foam concrete walls, steel wire mesh and pre-embedded tie bars, refer to figure 1 , figure 2 , image 3 , Figure 4 Figure 5 , Figure 6 , the reinforced concrete columns include main columns 10, 14, 23, 8 of the outer wall frame and transitional columns 5, 6, 7, 12, 13, 15, 16, 17, 18, 19, 24, refer to figure 1 , figure 2 , image 3 , Figure 4 , the foam concrete wall includes the exterior wall foam concrete wall 11 and the same interior wall foam concrete wall 20, the wall frame main columns 10, 14, 23, 8 and transition columns 5, 6, 7, 12, 13, 15, 16, 17, 18, 19, 24 have the same pre-embedded tie bars as pre-embedded tie bars 2, main columns 10, 14, 23, 8 of the outer wall frame and transition columns 5, 6, 7, 12, 13 , 15, 16, 17, 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com