Combination frame module, component frame module and tool set structure and installing and dismantling method thereof

A combination frame and component technology, which is applied in the fields of formwork/formwork components, formwork/formwork/work frame, and on-site preparation of building components, can solve the problems of high-altitude operation, high construction risk, and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

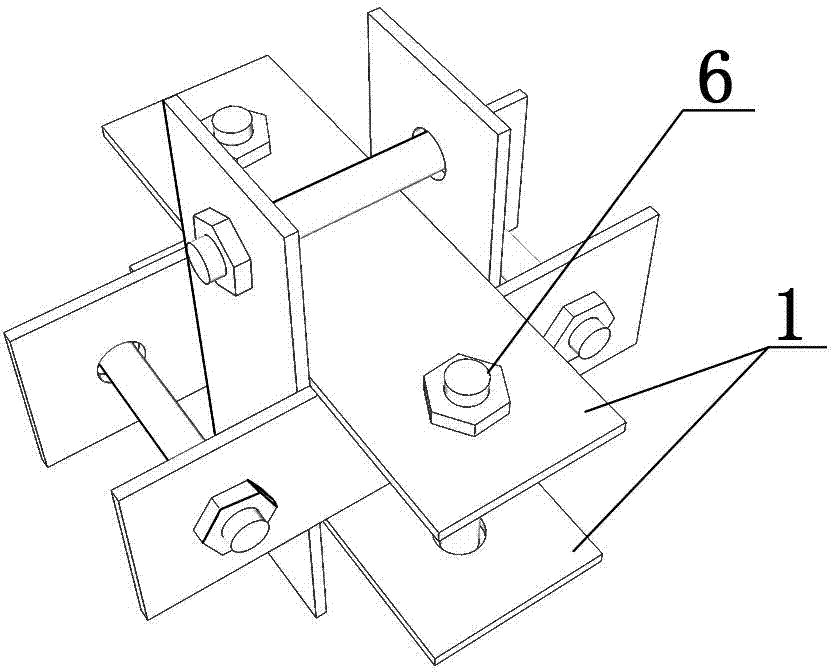

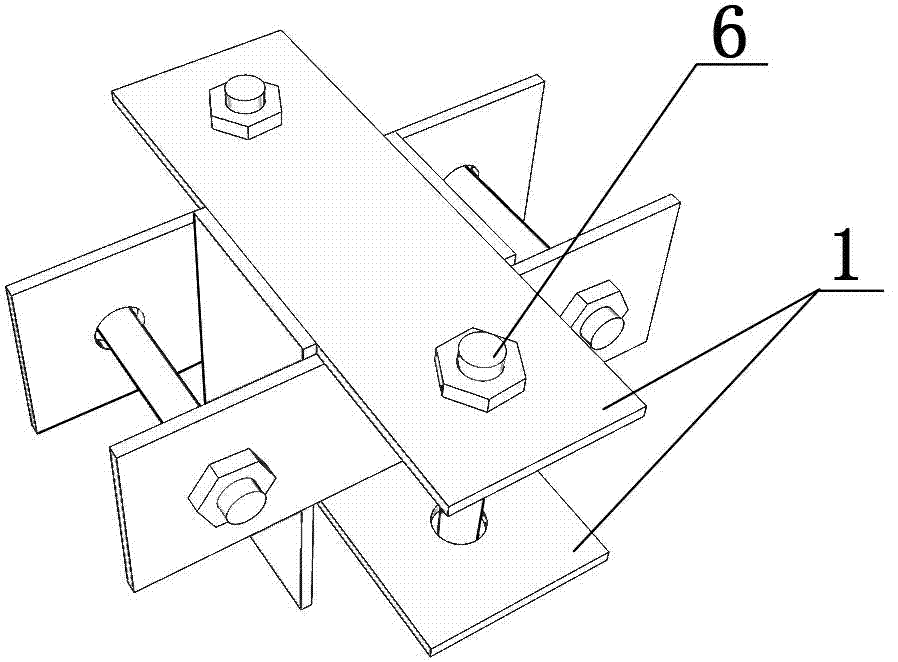

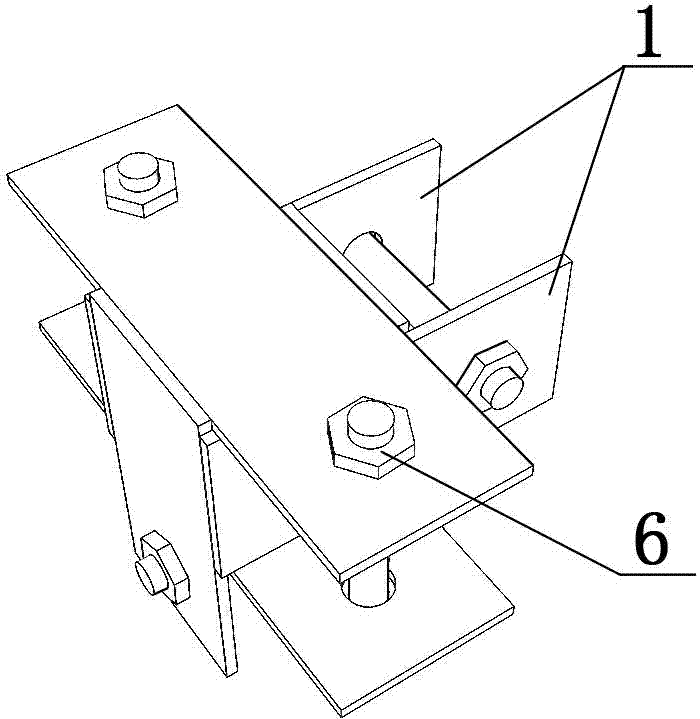

[0169] Examples see Figure 1-34 As shown in this combination frame mold, the combination frame mold is composed of a mold frame and a template combination.

[0170] The mold frame is a rectangular mold frame composed of one mold frame element, or a grid mold frame formed by splicing two or more mold frame elements.

[0171] The mold frame elements are rectangular mold frame elements formed of four frame parts facing each other in parallel and connected with each other by splint joints, and more than two mold frame elements are connected with each other by splint joints.

[0172] The mold frame element includes standard series, among which:

[0173] Standard width series include 600mm, 750mm, 900mm, 1200mm, 1500mm, 1800mm.

[0174] Standard length series include: 1200mm, 1800mm, 2400mm, 2700mm, 3000mm, 3300mm, 3600mm.

[0175] When the length of the frame is greater than or equal to 1200mm, the frame is a steel standard length frame; the standard length frame includes 900mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com