Descend control device

A technology of slow descender and slow flow port, which is applied in the direction of basic structure engineering, architecture, building structure, etc. It can solve the problems of prolonging the construction period, heavy maintenance workload, and high transportation cost, so as to reduce construction cost and reduce construction costs. The effect of simple construction period and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

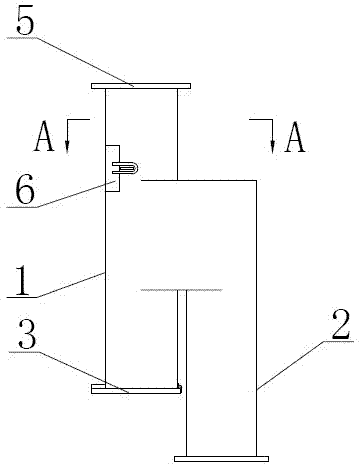

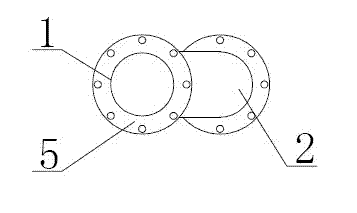

[0028] Embodiment one: see Figure 1 to Figure 5 , a buffer of the present invention, comprising a slow descender body, the slow descender body is formed by placing a feed pipe 1 and a discharge pipe 2 side by side to communicate with each other, and the diameter of the feed pipe and the discharge pipe is 270mm~ 330mm, there is a cleaning valve 3 at the bottom of the feed pipe 1, and a slow flow port 4 is opened in the middle of the feed pipe 1, the height of the slow flow port is 450mm~550mm, the top of the feed pipe 1 and the discharge pipe 2 are fixed with a connecting flange 5, and an observation valve 6 is also provided on the feed pipe 1, which is convenient for adjusting and observing the flow rate of the material, and can also clean the inner cavity in time. The height of the buffer section 7 between the cleaning valve 3 and the slow flow port 4 is 400mm-750mm.

Embodiment 2

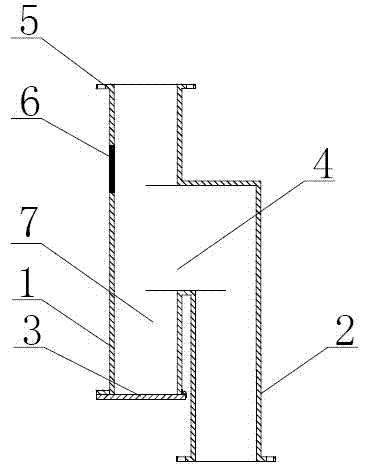

[0029] Embodiment two: see Figure 6 , Figure 7 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that a connecting flange 5 is provided on the top of the feed pipe 1 of the described descender, and the discharge pipe The bottom end of 2 is provided with slip flow port 8, and the slip flow plate 9 on the lower side of slip flow port 8 is placed obliquely, and the inclination angle is at 10°~15°.

[0030] Working process of the present invention is:

[0031] During the vertical transportation of concrete, because the concrete falls through the vacuum chute or BOX pipe too fast, it will cause serious damage to the belt conveyor installed on the lower side of the pipeline. During concrete transportation, a section of soft concrete will be directly stored in the buffer section 7, which can not only absorb the impact force of concrete falling, but also make the concrete fluid in the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com