Well head device with combined sealing, double-tube gas injection and remote control

A remote control, combined sealing technology, used in sealing/isolation, wellbore/well components, earth-moving drilling, etc. Adapt to the problems of long-distance control of oil and gas wells, and achieve the effect of light weight, compact structure and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

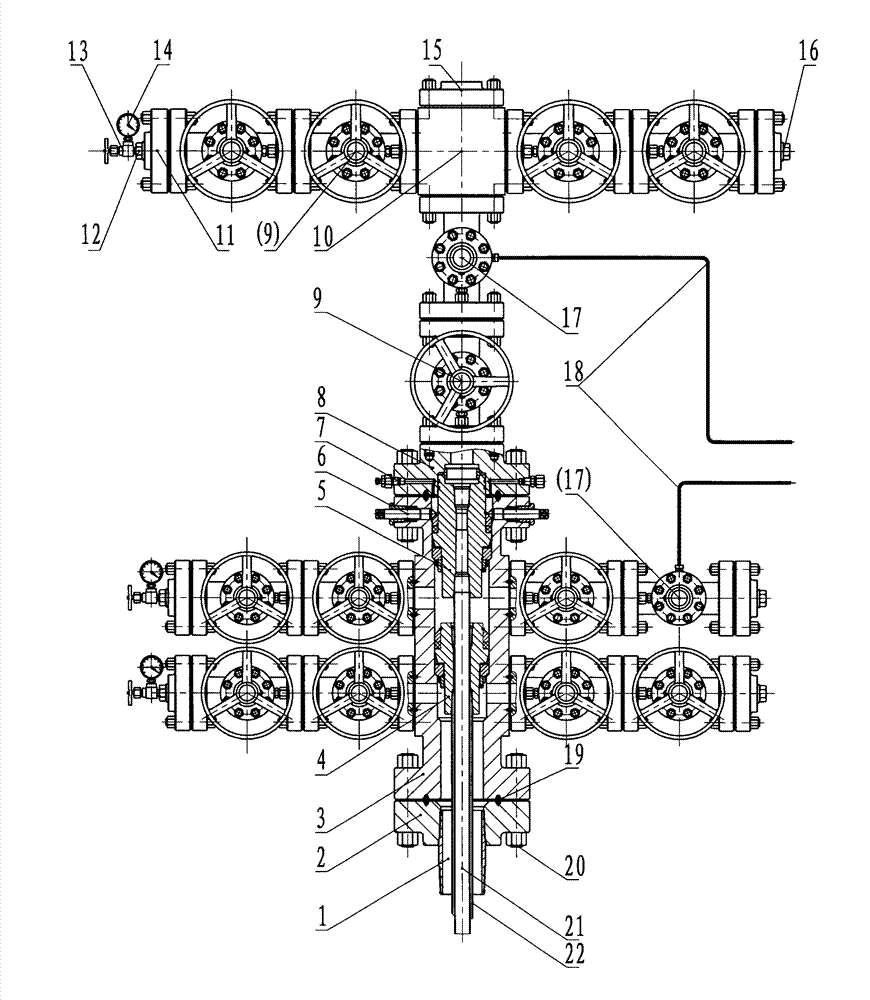

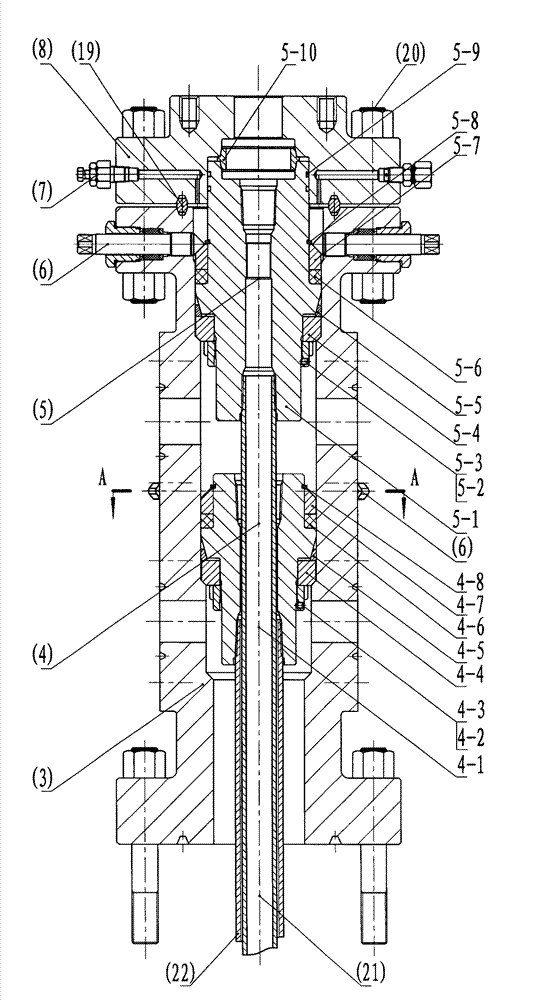

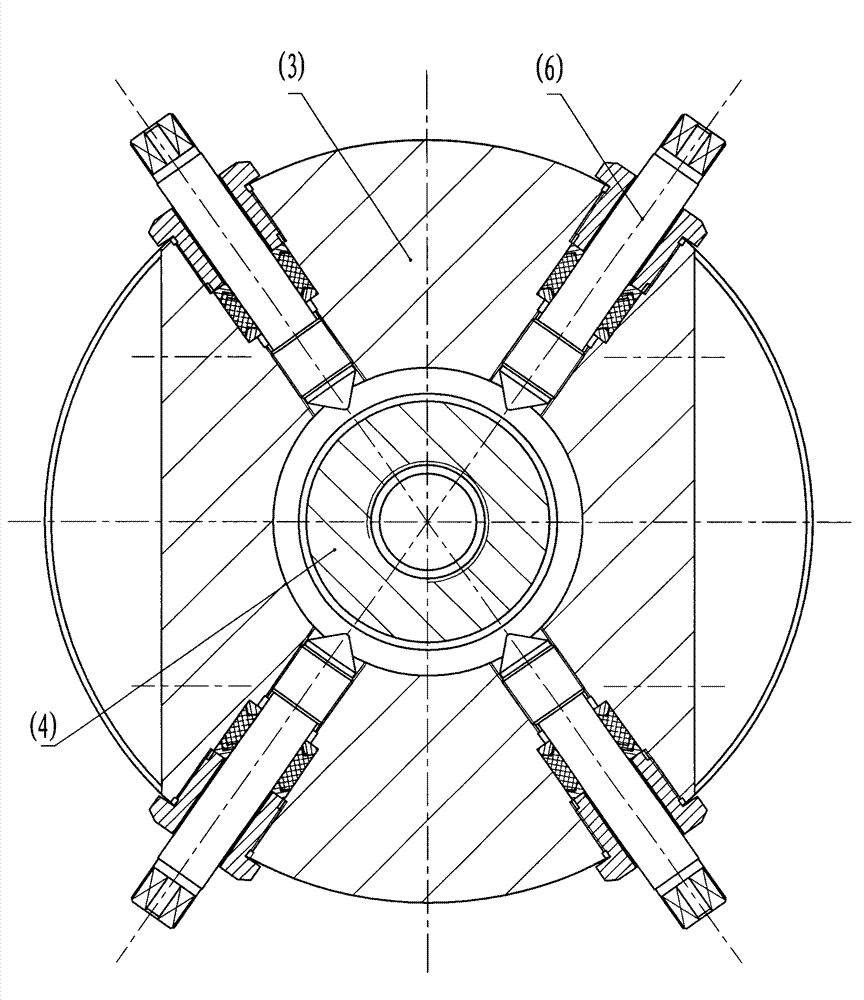

[0011] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0012] figure 1 Among them, the present invention is composed of casing connectors, tubing heads, Christmas trees, gas injection pipe valves, measurement and control pipe valves, seals, and connectors. Casing connectors mainly include casing nipples (1) and casing flanges (2); tubing heads mainly include tubing head shells (3), lower hanger parts (4), upper hanger parts (5) and Jacking screw part (6); Christmas tree mainly includes grease injection valve (7), tubing reducing joint (8), flat valve (9), cross (10), threaded flange (11), inner joint (12) , stop valve (13), pressure gauge (14), blind hole cover plate (15), pipe plug (16) and hydraulic control valve (17). There are two rows of gas injection pipe valve parts connected to one side of the oil pipe head, mainly including two flat valves (9) or one flat valve (9) plus a hydraulic control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com