Air cooling heat dissipation thermoelectric cooler (TEC) electric refrigeration charge coupled device (CCD) Dewar

An electric refrigeration and air-cooling technology, which is applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., to achieve the effect of large refrigeration temperature difference, fast cooling speed, fast and simple refrigeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

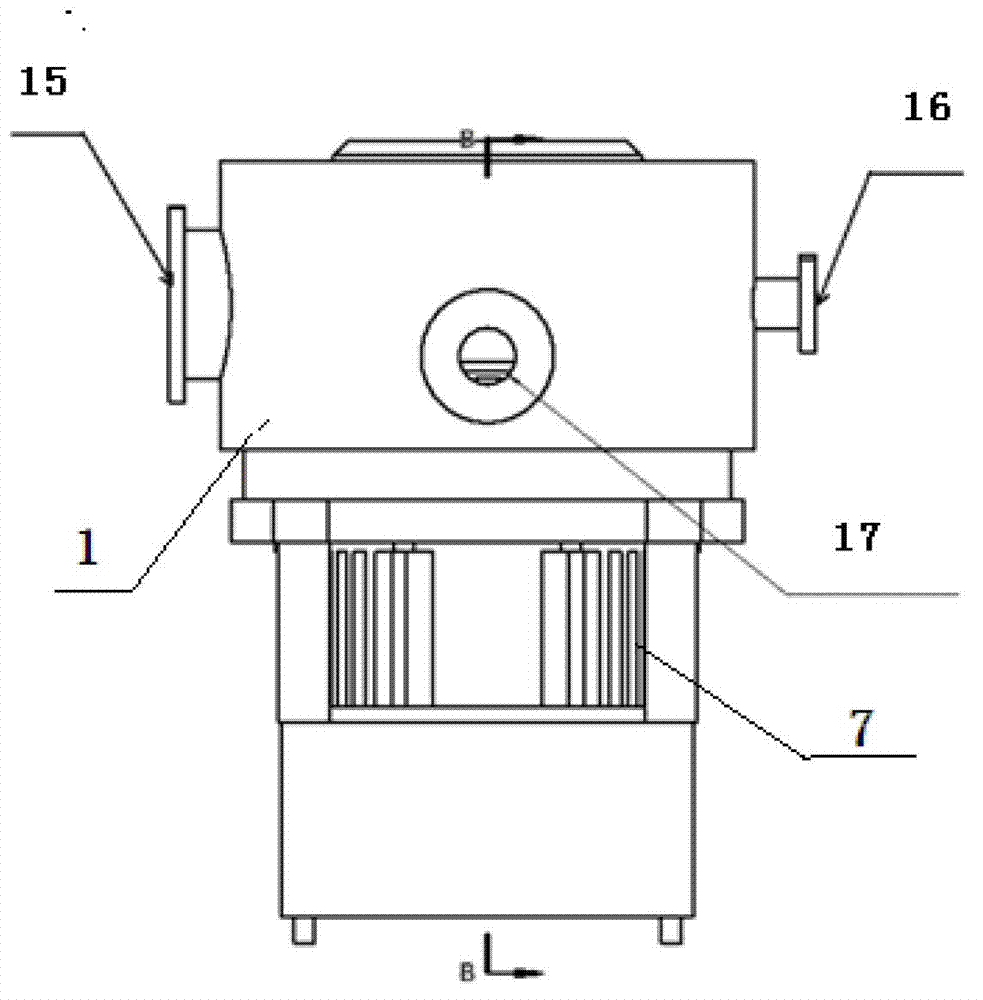

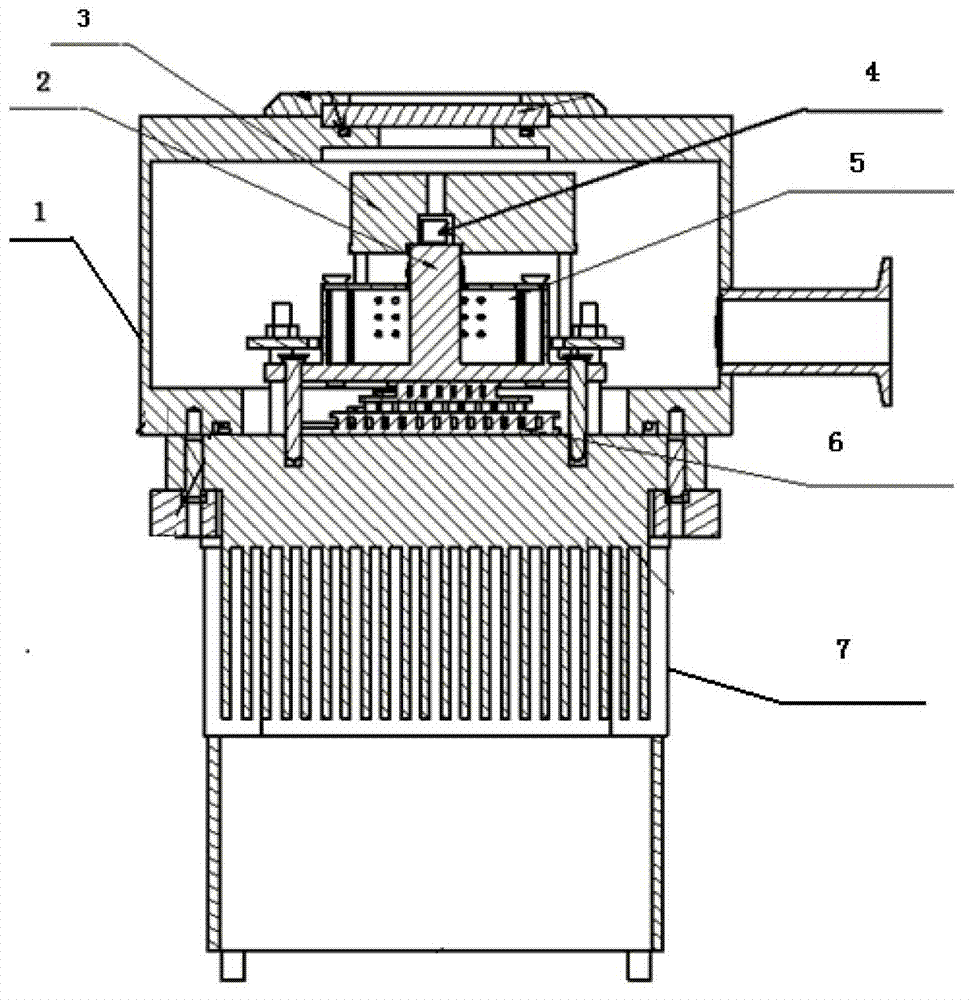

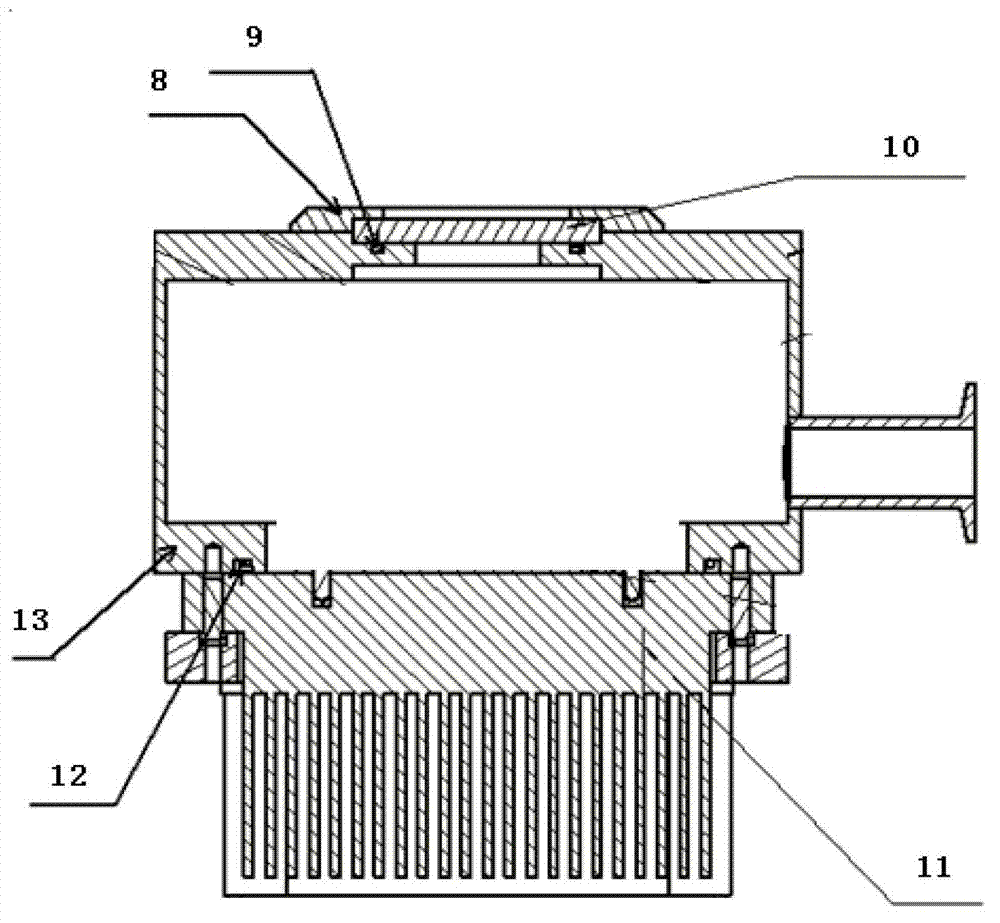

[0029] Such as figure 1 , 2 As shown, this embodiment includes a vacuum dewar 1, a CCD detector 3, a three-stage TEC refrigeration sheet 6, an air-cooled heat dissipation system 7, and a molecular sieve 5; figure 1 , 3 , 4, the air-cooled heat dissipation system 7 is composed of a heat sink 11 and a fan 14 connected. Such as figure 1 , 3 As shown, the vacuum dewar 1 includes a vacuum cavity 13, and the upper part of the vacuum cavity 13 is fixedly provided with an optical sealing glass 10 by a glass sealing pressure ring 8 and a glass O-shaped sealing ring 9 to achieve a sealing effect; the vacuum cavity A CCD detector 3, a molecular sieve 5 and a three-stage TEC cooling plate 6 are arranged inside the body 13, and the bottom is sealed by a heat sink 11; 13 is sealed and connected, and is connected to the hot end of the three-stage TEC refrigeration sheet 6 inside the vacuum chamber 13 for heat conduction; the lower end of the heat sink 11 is processed into a heat dissipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com