Assembly device and method for horizontal body of dry amorphous alloy transformer

A technology of amorphous alloy and transformer, which is applied in the field of dry-type amorphous alloy transformer horizontal body assembly, can solve the problems of low assembly efficiency, poor consistency of technical performance indicators, unstable performance, etc., and achieve product quality and production Efficiency improvement, good consistency of technical performance indicators, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

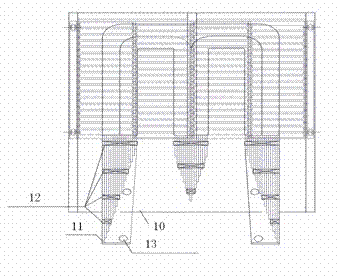

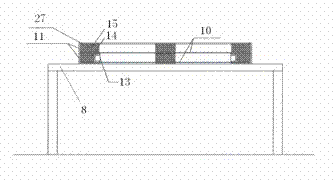

[0015] A device for assembling a horizontal body of a dry-type amorphous alloy transformer, including a body platform 6, characterized in that a rolling platform 8 is provided behind the body platform, and a sliding trolley 9 is provided in front of the body platform , the body platform 6 is provided with a lifting adjustment device 7 .

[0016] A method for assembling a dry-type amorphous alloy transformer with a horizontal body, specifically comprising the following steps:

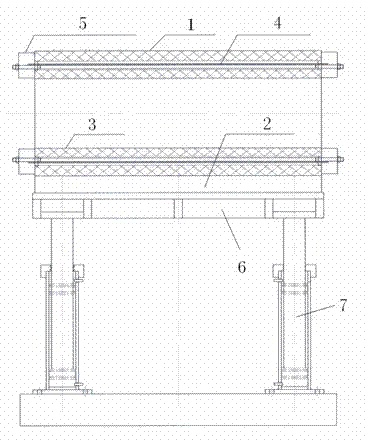

[0017] Step A, the positioning and fixing of the high and low voltage coils (carried out on the body platform), the purpose is to fix the three sets of high voltage coils 2, low voltage coils 3 and the middle epoxy resin insulating cylinder 4 (if any) into a whole (Such as figure 1 shown).

[0018] a. First, lead out the terminal leads of the three high-voltage coils 1 for spar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com