Light-emitting diode packaging module

A technology for light-emitting diodes and packaging modules, which is applied in electrical components, electrical solid-state devices, circuits, etc., and can solve problems such as inability to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

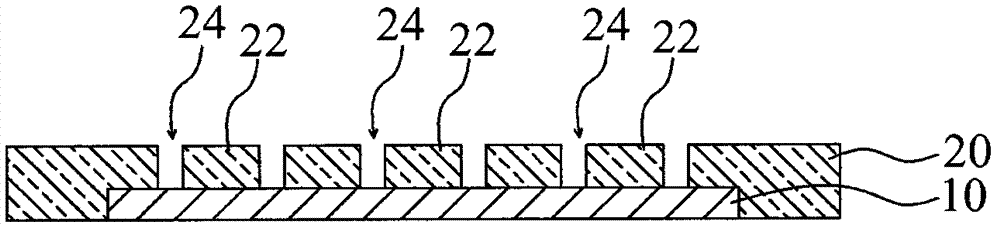

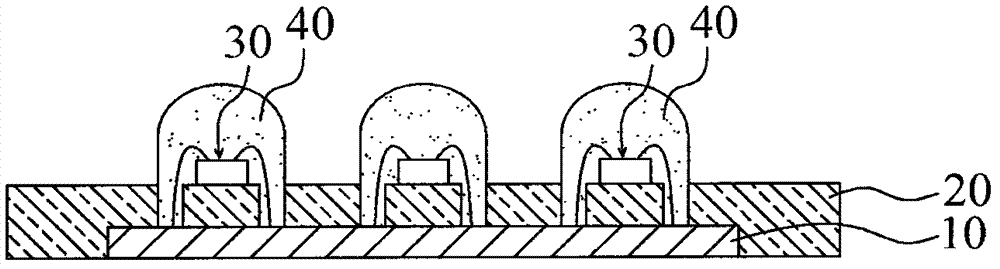

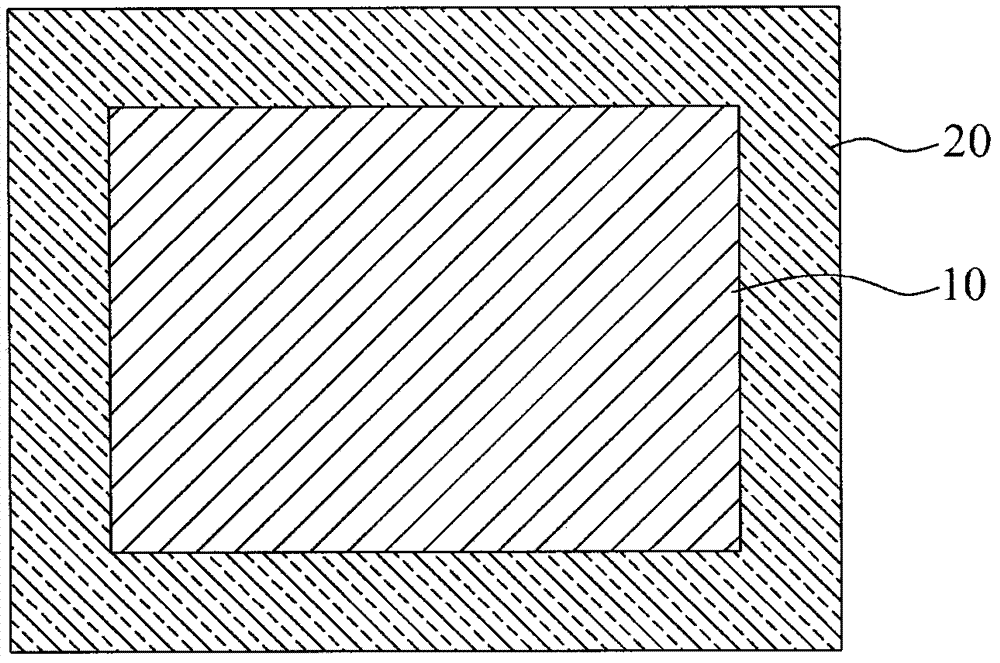

[0023] Its detailed description is as follows, and the preferred embodiment is only for illustration and not intended to limit the present invention. Figure 1A , Figure 1B and Figure 1C It is a schematic diagram of an LED packaging module according to an embodiment of the present invention.

[0024] In this example, if Figure 1A As shown, the LED packaging module includes a circuit board 10 . A metal plate 20 directly covers the entire upper surface of the circuit board 10 . The metal plate 20 has a plurality of chip carriers 22 and a plurality of openings 24 . The opening 24 exposes a wire bonding area on the upper surface of the circuit board 10 . The opening 24 is disposed adjacent to the chip carrier 22 .

[0025] Next, please refer to Figure 1B , a plurality of chips 30 are respectively arranged on each chip carrier 22 one by one. A plurality of wires (not shown in the figure) are electrically connected to the bonding area of the chip 30 and the circuit board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com