Double beam integrated feed network

A feeding network and dual-beam technology, applied to circuits, electrical components, waveguide devices, etc., can solve the problems of difficult phase error, large debugging workload, and small debugging workload, so as to reduce debugging work and improve reliability Performance and reduced debugging workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

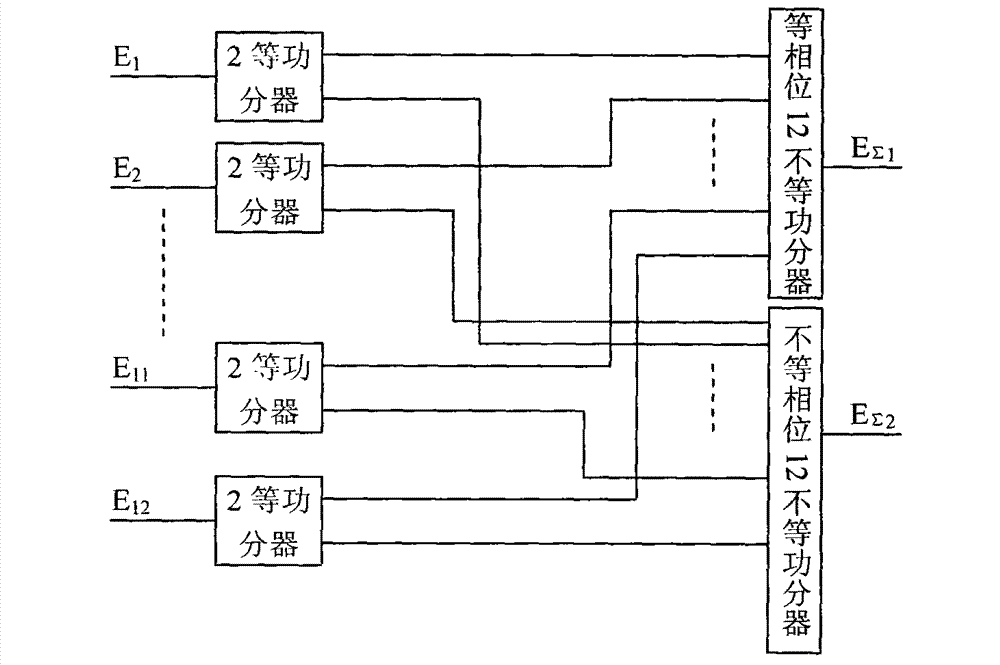

[0022] The first scheme adopts stripline multi-layer structure, designs 2 equal power dividers and equal phase 12 unequal power dividers 1 in one plane, and designs unequal phase 12 unequal power dividers 2 in another plane Inside, the signal transmission between the two layers is realized by metallized holes. This solution has high requirements on the processing technology of the microstrip board, and it is extremely difficult to realize the project.

Embodiment 2

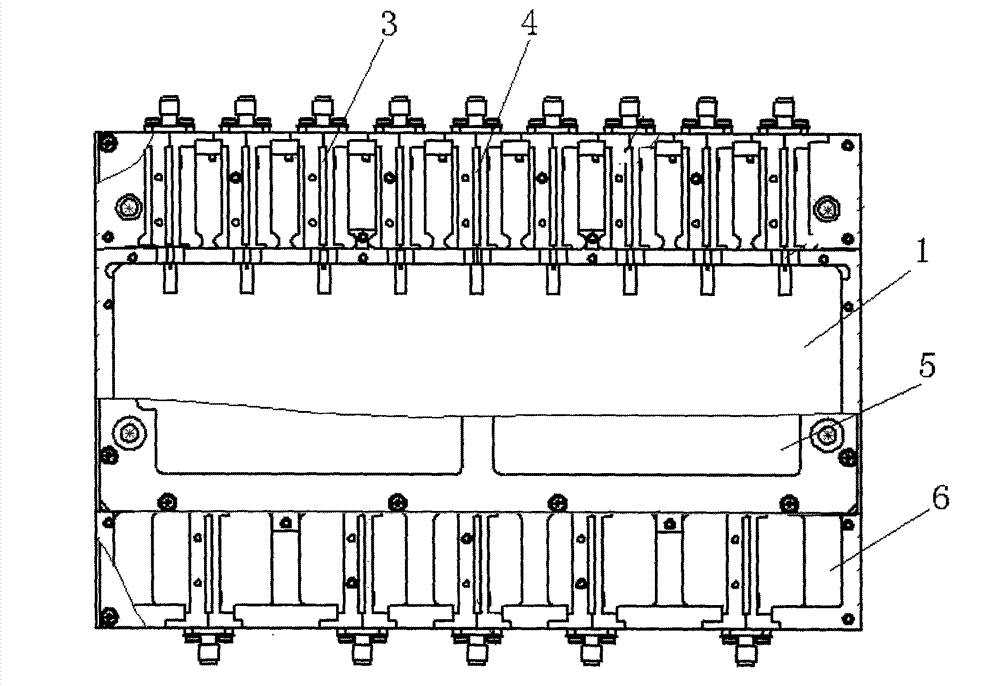

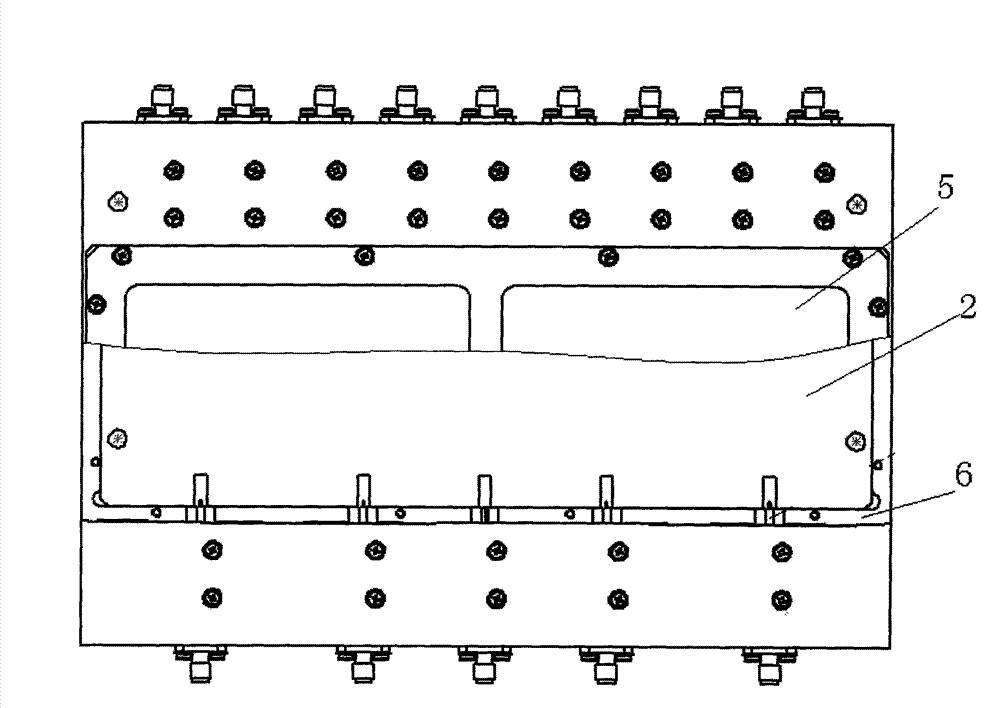

[0024] In the second scheme, the 2 equal power dividers and the 12 unequal power dividers with different phase characteristics are designed separately. The connection structure realizes the signal transmission between the two, and all the devices are integrated in a feed network box seat 6. This scheme has lower requirements on the processing technology of the microstrip board, but it has a higher impact on the structural design and The processing puts forward higher requirements, and the engineering realization is relatively easy. The best embodiment of the present invention is to adopt second kind of scheme to realize.

[0025] refer to figure 2 , image 3 . In the following embodiments, a dual-beam feeding network with a size of 200×132×16.5 mm is taken as the best embodiment. Since there are many devices that make up the dual-beam feed network, the feed network body is structurally divided into four parts: equal phase 12 unequal power divider circuit board 1, unequal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com