White rigid decorative member

A decorative component, hard technology, applied in the direction of transportation and packaging, vacuum evaporation plating, coating, etc., can solve the problems of low damage resistance, film thickness cannot be thickened, low hardness of Cr coating film, etc., to achieve durability Effects of improved damage resistance, improved damage resistance, and high damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

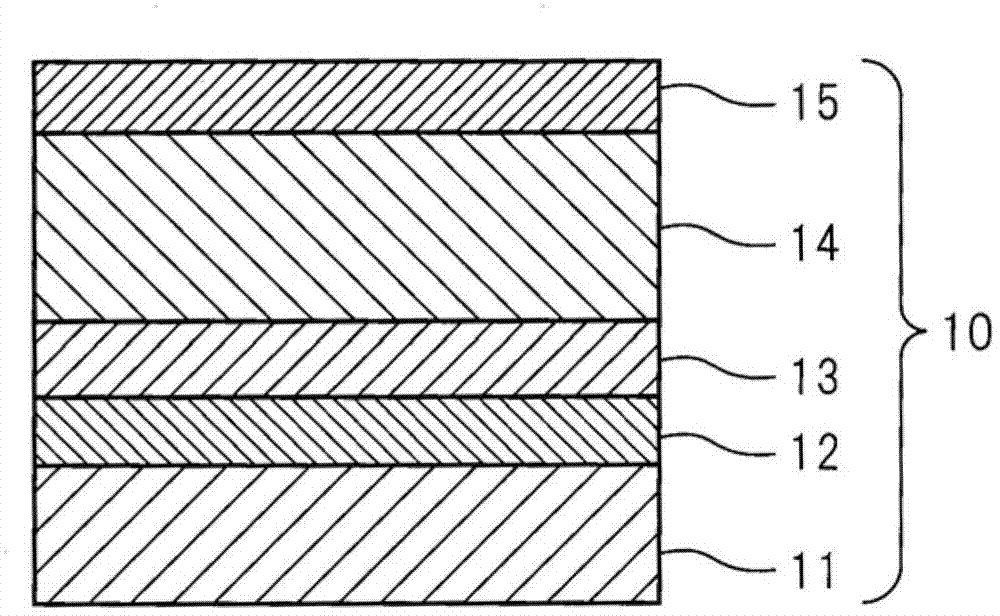

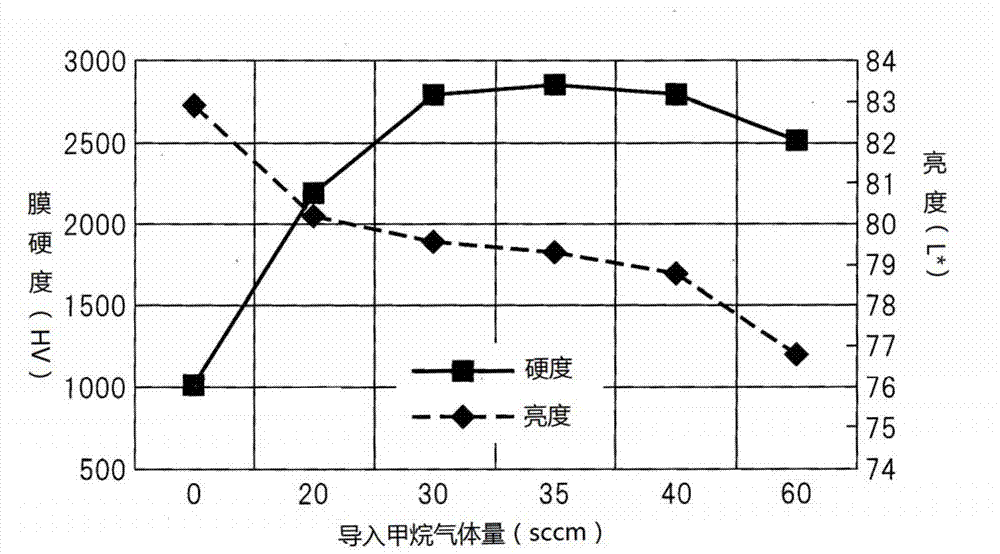

[0109] The first embodiment of the white hard decorative component of the present invention adopts figure 2 , image 3 and Figure 4 Be explained. figure 2 is a schematic cross-sectional view of a white hard decorative member 20, image 3 is a diagram showing the change in hardness and brightness corresponding to the amount of methane gas introduced, Figure 4 is a damage resistance measurement chart of the white rigid decorative member 20 .

[0110] The composition of the sputtering target in Example 1 is a sintered body of 45wt% Mo and 55wt% Nb. A SUS316L material specified in JIS was used as the base material 21 , and an adhesion layer 22 composed of a 0.1 μm MoNb alloy lower oxide was formed on the base material 21 by a sputtering method. Then, while introducing a trace amount of oxygen, a 0.2 μm gradient adhesion layer 23 of a MoNb alloy oxycarbide film in which methane is gradually increased is formed. Then, a 2.2 μm thin-film wear-resistant layer 24 composed of ...

Embodiment 2

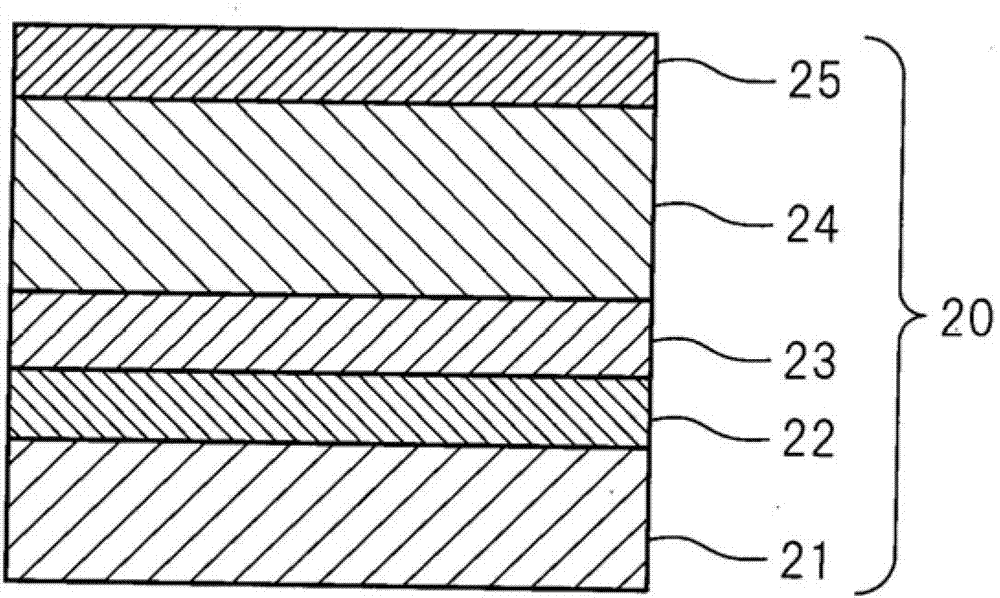

[0122] use Figure 5 , Figure 6 , Figure 7 A second embodiment of the white rigid decorative member of the present invention will be described. Figure 5 is a schematic cross-sectional view of a white hard decorative member 30, Figure 6 is a graph showing the change in hardness and brightness corresponding to the amount of methane gas introduced, Figure 7 is a graph showing the damage resistance measurement of the white rigid decorative member 30 .

[0123] The composition of the sputtering target in Example 2 is a sintered body of 30wt% Mo and 70wt% Ta. A SUS316L material specified in JIS was used as the base material 31 , and an adhesion layer 32 composed of a 0.1 μm MoTa alloy lower oxide was formed on the base material 31 by sputtering. Then, a 0.2 μm gradient adhesion layer 33 of a MoTa alloy oxycarbide film in which methane gas is gradually increased is formed. Then, a 2.0 μm thin-film wear-resistant layer 34 composed of a MoTa alloy carbide film was formed. T...

Embodiment 3

[0136] use Figure 8 , Figure 9 , Figure 10 A third embodiment of the white rigid decorative member of the present invention will be described. Figure 8 is a schematic cross-sectional view of a white hard decorative member 40, Figure 9 is a graph showing the change in hardness and brightness corresponding to the amount of methane gas introduced, Figure 10 is a graph showing the damage resistance measurement of the white rigid decorative member 40 .

[0137]The composition of the sputtering target in Example 3 is a sintered body of 50wt%Mo, 25wt%Nb, and 25wt%Ta. Since Mo, Nb, and Ta are in continuous solid solution, they can be adjusted to any ratio. A SUS316L material specified in JIS was used as the base material 41 , and an adhesion layer 42 composed of a 0.1 μm MoNbTa alloy lower oxide was formed on the base material 41 by sputtering. Then, a 0.2 μm gradient adhesion layer 43 of a MoNbTa alloy oxycarbide film in which methane gas is gradually increased is formed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com