Extruding-type coating head with precisely controlled head and tail thicknesses

A precision-controlled, extrusion-type technology, applied to the surface coating device, coating, etc., to achieve the effect of convenient debugging, increased thickness, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

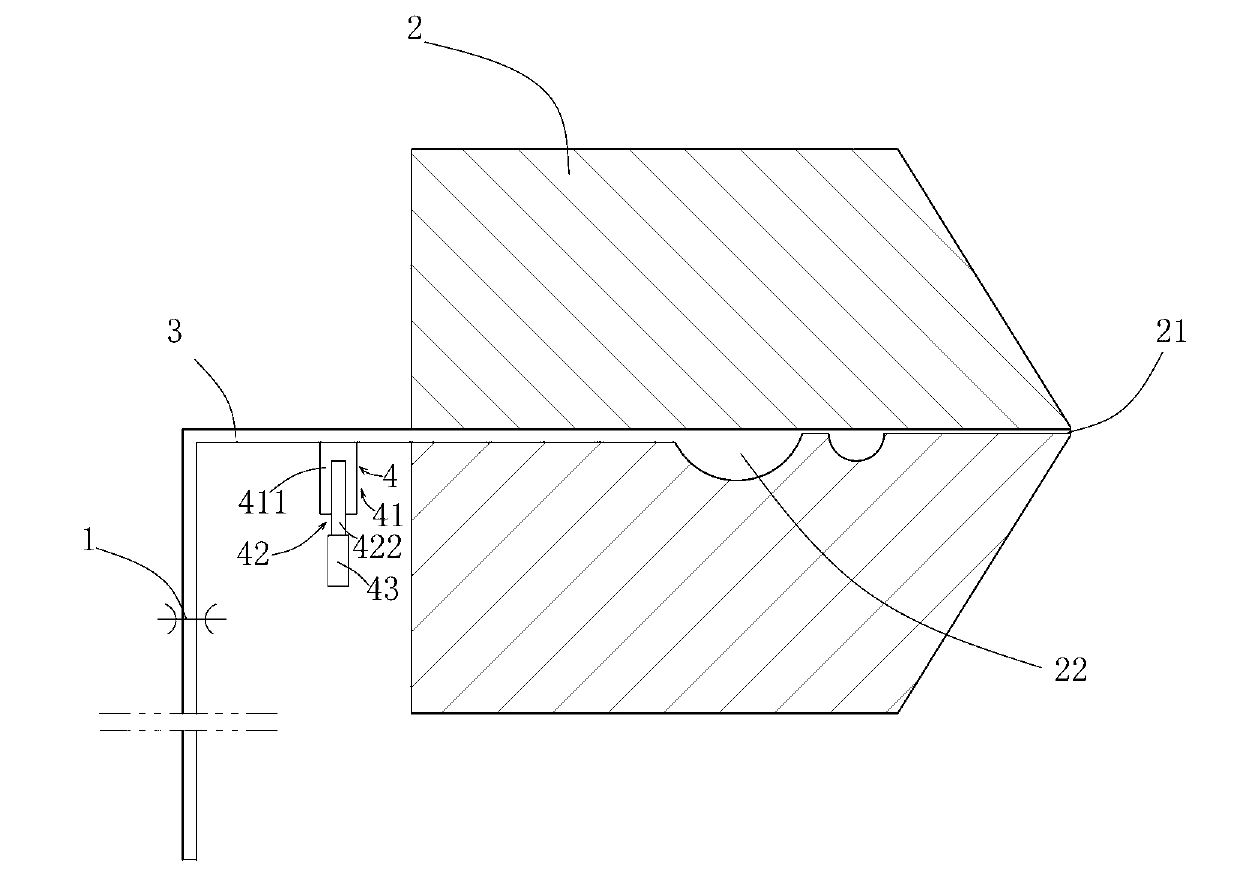

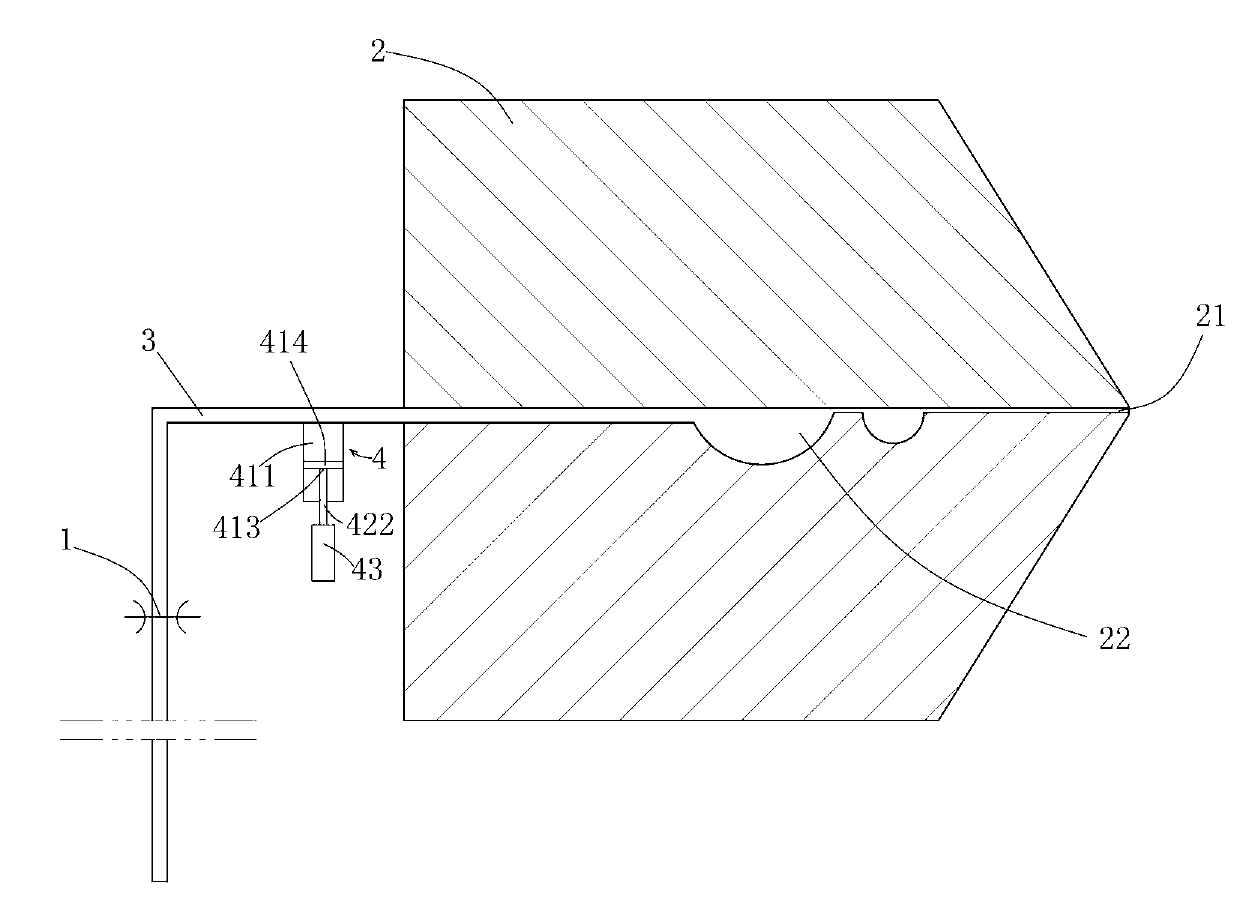

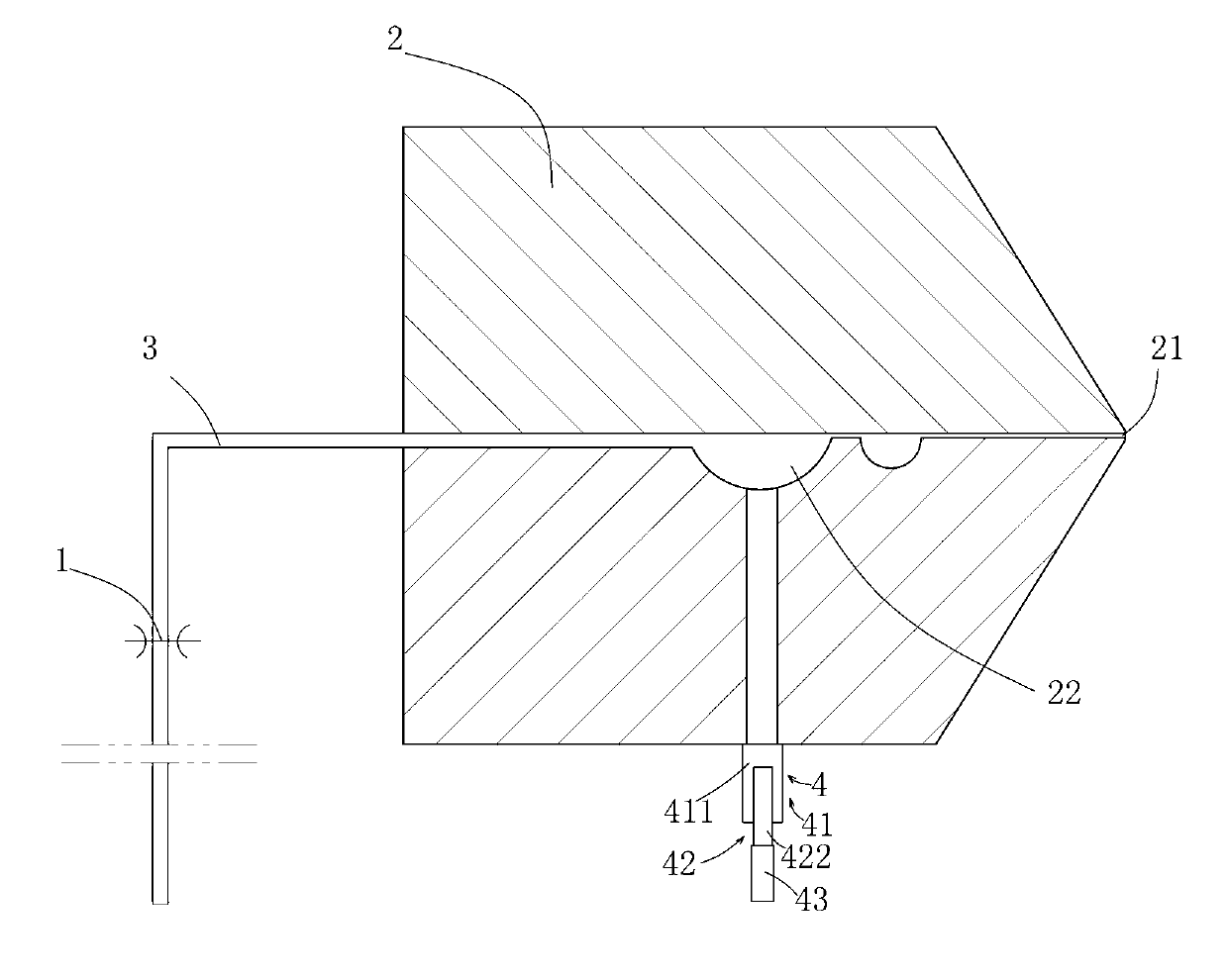

[0026] See figure 1 , figure 1 Disclosed is an extrusion coating head whose head and tail thickness can be precisely controlled, including a high-speed switching valve 1 and an extrusion head 2. The high-speed switching valve 1 is connected to a feed pump (not shown) and the extrusion head. Between the pressure heads 2, it is used to intermittently cut off the feed channel 3 between the high-speed switching valve 1 and the slit 21 of the extrusion head 2, and the feed channel 3 is provided below the feed channel 3. The variable volume filling device 4 used to change the slurry flow rate in the feed channel 3 (the reason why the variable volume storage device 4 is arranged at the bottom is to allow the feed pump to first set the variable volume storage device when feeding. The device 4 is filled with slurry), the variable storage device 4 includes a storage device main body 41 and a control member 42 for controlling the capacity change of the storage device main body 41, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com