Scaling method of drawing procedure processing data

A drawing process and processing data technology, which is applied in the scaling field of drawing process processing data, can solve the problems of prolonging the mold manufacturing cycle, affecting the dimensional accuracy of products, and enhancing the labor intensity of fitters, so as to reduce labor intensity, eliminate deviation, The effect of improving the accuracy of dynamic simulation adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] According to user requirements, follow the steps below:

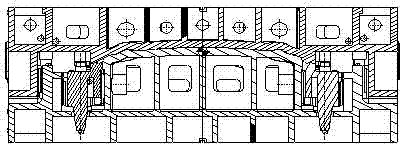

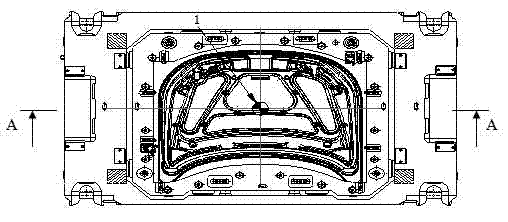

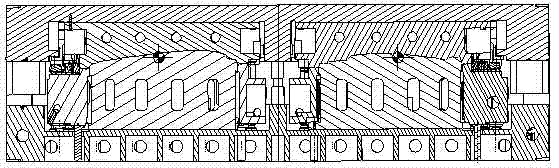

[0020] 1) According to the specific mold structure, carry out fine mold surface design, and design the surface and contour of each part of the mold in the drawing process (generally: punch, die, and pressing ring) according to 1:1.

[0021] 2) Set the scale center coordinate system according to different mold forms;

[0022] (1) Setting of the scaling center of the single-slot mold

[0023] For the setting of the reduction ratio center of the single-slot mold, the geometric center of the part should be considered, and the trend of ensuring the reduction ratio is centered on the geometric center of the part, and gradually expands radially to the outside of the part. Generally, the reduction center 1 of the processing data design of a single-slot mold should be set as far as possible at the pressure center set by the stamping process, that is, the part reference point set by the stamping process, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com