Metal mold gravity casting automatic production line

An automated production line, gravity casting technology, applied in foundry, casting equipment, metal processing equipment, etc., can solve the problems of high labor intensity, large labor demand, harsh production environment, etc., to save labor costs, mature technology, The effect of reducing labor injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

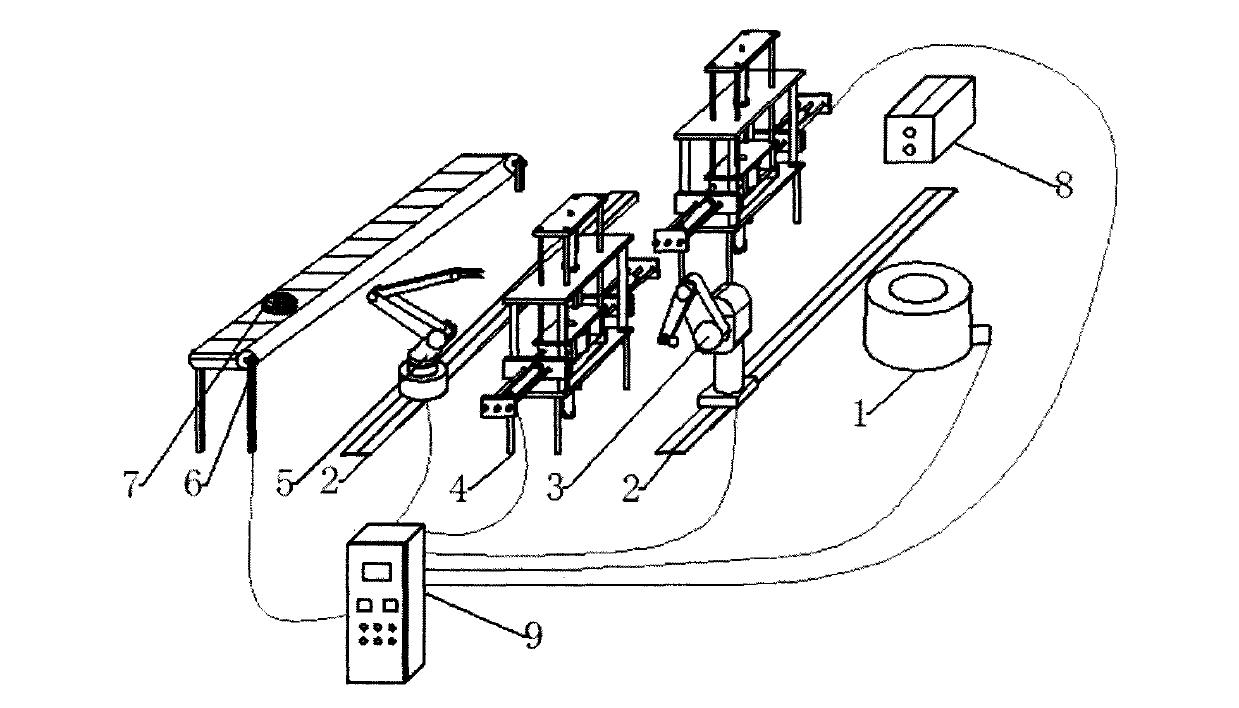

[0014] combine figure 1 An automatic production line for metal mold gravity casting provided by the present invention is described.

[0015] An automatic production line for metal mold gravity casting, including a molten metal holding furnace 1, 2 to 5 gravity casting machines 4, characterized in that it also includes a linear guide rail 2, an automatic pouring machine 3, an automatic picker 5, and a mold spray system, casting conveyor belt 6, and integrated control system 9.

[0016] 2 to 5 gravity casting machines 4 are arranged in a straight line, share the same hydraulic tank 8, and are located in the middle of the two linear guide rails 2. The automatic pouring machine 3 is located between the holding furnace 1 and the gravity casting machine 4 . The automatic picker is located between the gravity casting machine 4 and the conveyor belt 6 . The holding furnace 1 is located on the vertical line of the linear guide rail 2 . The integrated control system 9 can integrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com