Multi-element micro-alloyed high-strength aluminum-manganese alloy and preparation method thereof

A micro-alloying, aluminum-manganese alloy technology, applied in the field of aluminum alloys, can solve the problems that it is difficult to meet the requirements of thinning and lightweight of automobiles, and the strength of aluminum alloys is not high enough, so as to improve the quality of sealing holes, enhance corrosion resistance, improve The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

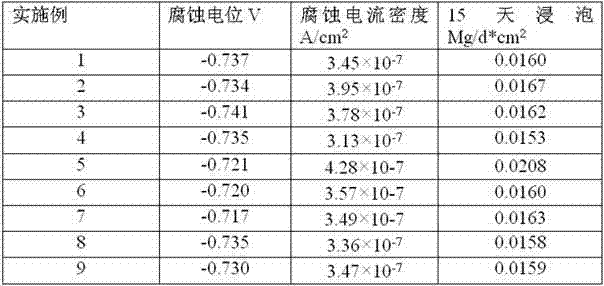

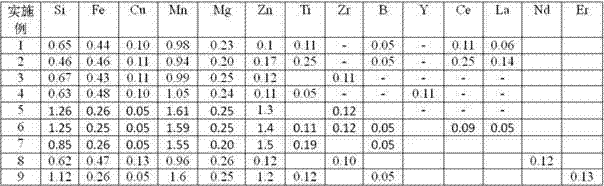

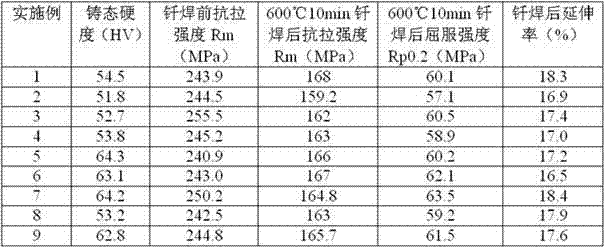

[0030] The high-strength aluminum-manganese alloys of Examples 1-9 are prepared according to the method described in the above summary of the invention, wherein the melting temperature, homogenization treatment temperature, hot rolling temperature and thickness, thickness of the alloy after cold rolling, annealing temperature, and annealing time are based on Product requirements and industry common sense are selected. The proportions of the components and weight percentages in the high-strength aluminum-manganese alloys of Examples 1-9 are shown in Table 1 below.

[0031] Table 1

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com