Electromagnetic paraffin prevention paraffin viscosity reduction device capable of changing frequency and strong field

An electromagnetic anti-wax and frequency-variable technology, which is applied in the direction of cleaning equipment, wellbore/well parts, earthwork drilling and mining, etc., can solve the problem of wax prevention, poor viscosity reduction effect, poor adaptability, magnetic field strength of electromagnetic wax anti-wax viscosity reducer Adjustment and other issues to achieve the effect of prolonging the cycle of pump inspection and pipeline wax removal, preventing wax precipitation, and improving oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

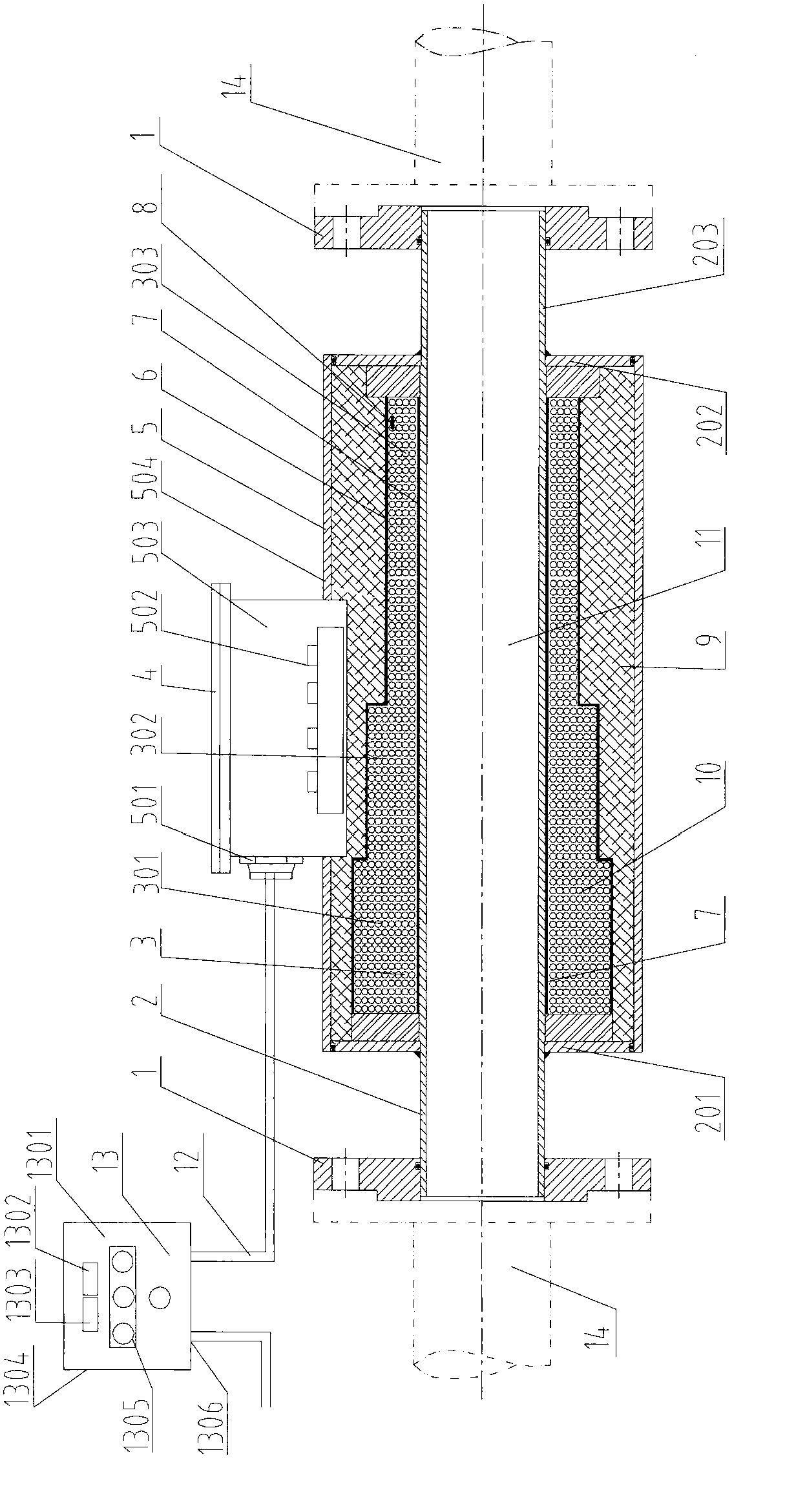

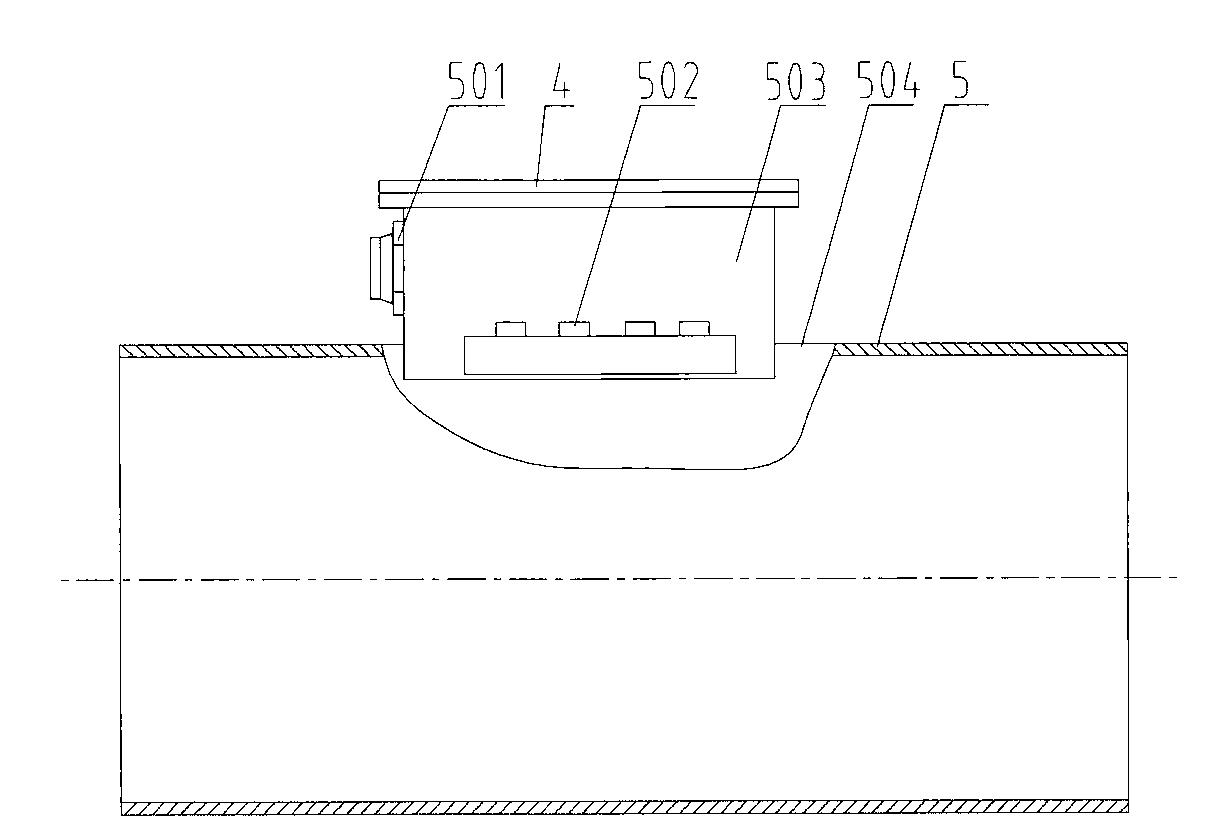

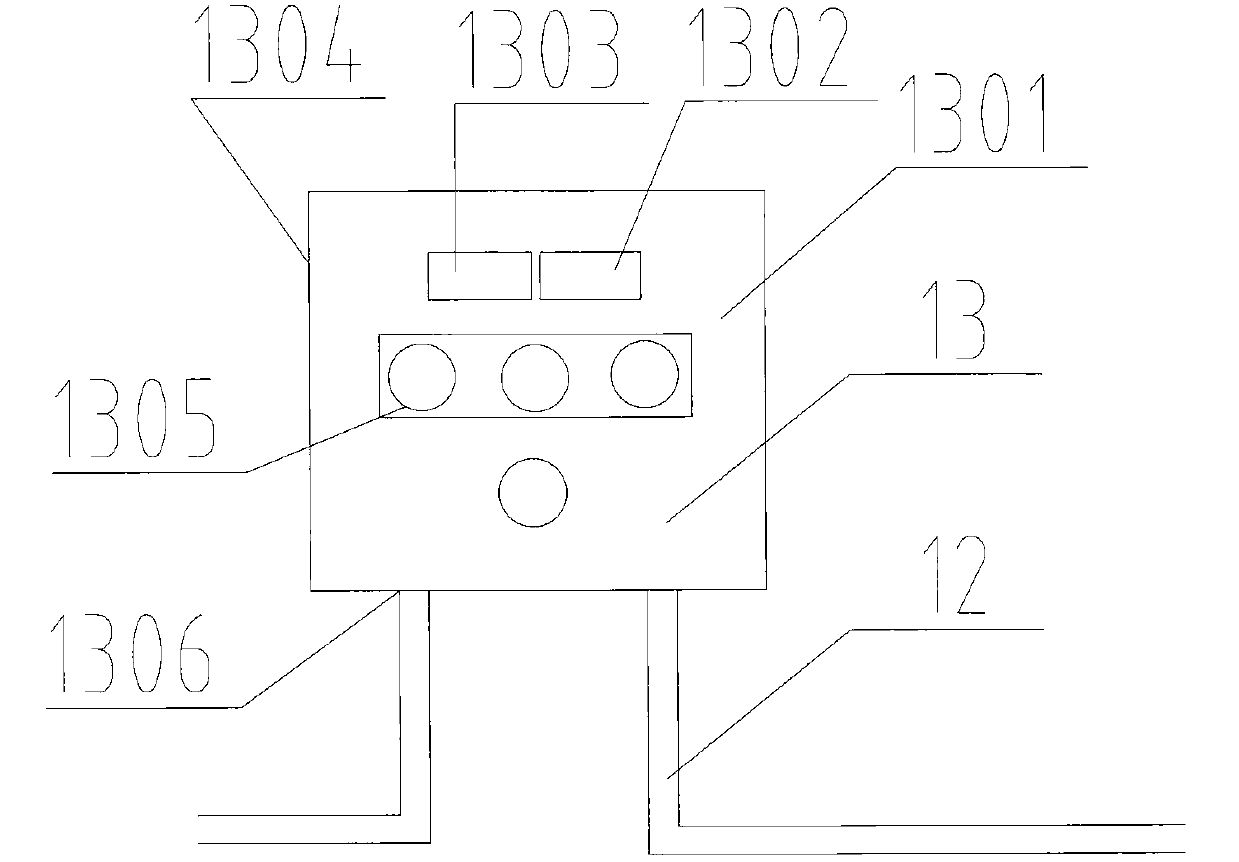

[0023] Such as figure 1 As shown, it is a structural schematic diagram of an electromagnetic wax-preventing viscosity reducer with variable frequency and variable intensity. The electromagnetic wax anti-viscosity reducer with variable frequency and variable intensity is composed of a magnetic field generator 11, a cable 12 and a power control box. Described magnetic field generator 11 consists of flange 1, inner tube 2, coil 3, junction box cover 4, casing 5, coil outer layer insulating paper 6, coil inner layer insulating paper 7, temperature sensor 8, waterproof insulating material 9 and The coil wire turns interlayer insulating paper 10, the inner tube 2 is arranged in the outer shell 5, and the two ends of the inner tube 2 are exposed outside the outer shell 5 and the exposed lengths are equal. Both ends of the inner tube 2 are provided with flanges 1 , and a coil 3 is provided inside the shell 5 . The inner tube 2 includes a hollow tube 203 and a left end plate 201 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com