Airtight type fuel air heater

An air heater, airtight technology, applied in air heaters, fluid heaters, air treatment equipment and other directions, can solve the problems of pollution, no design of exhaust outlet, inability to access sealed air ducts, etc., to achieve overall stability , the overall air tightness, good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

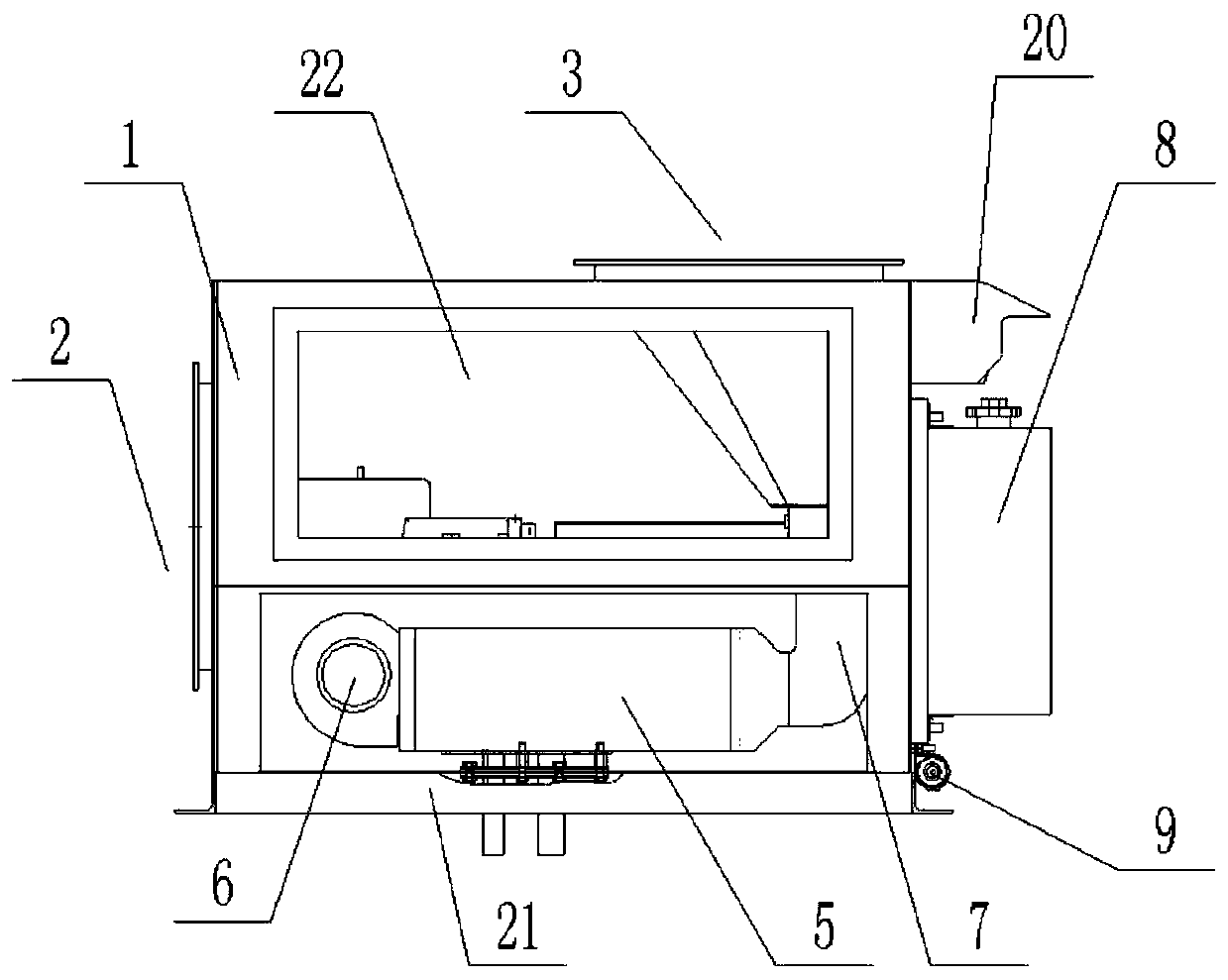

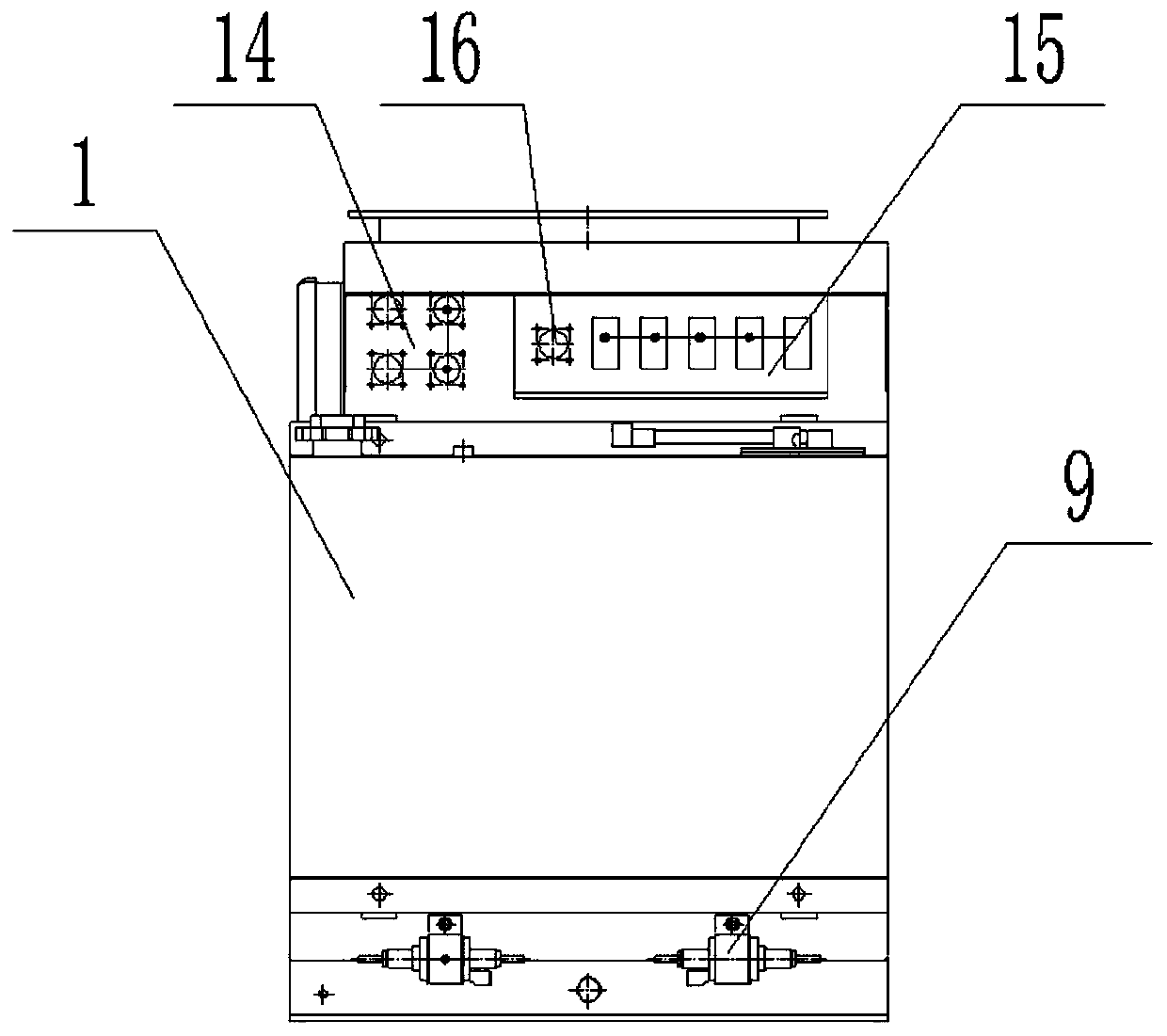

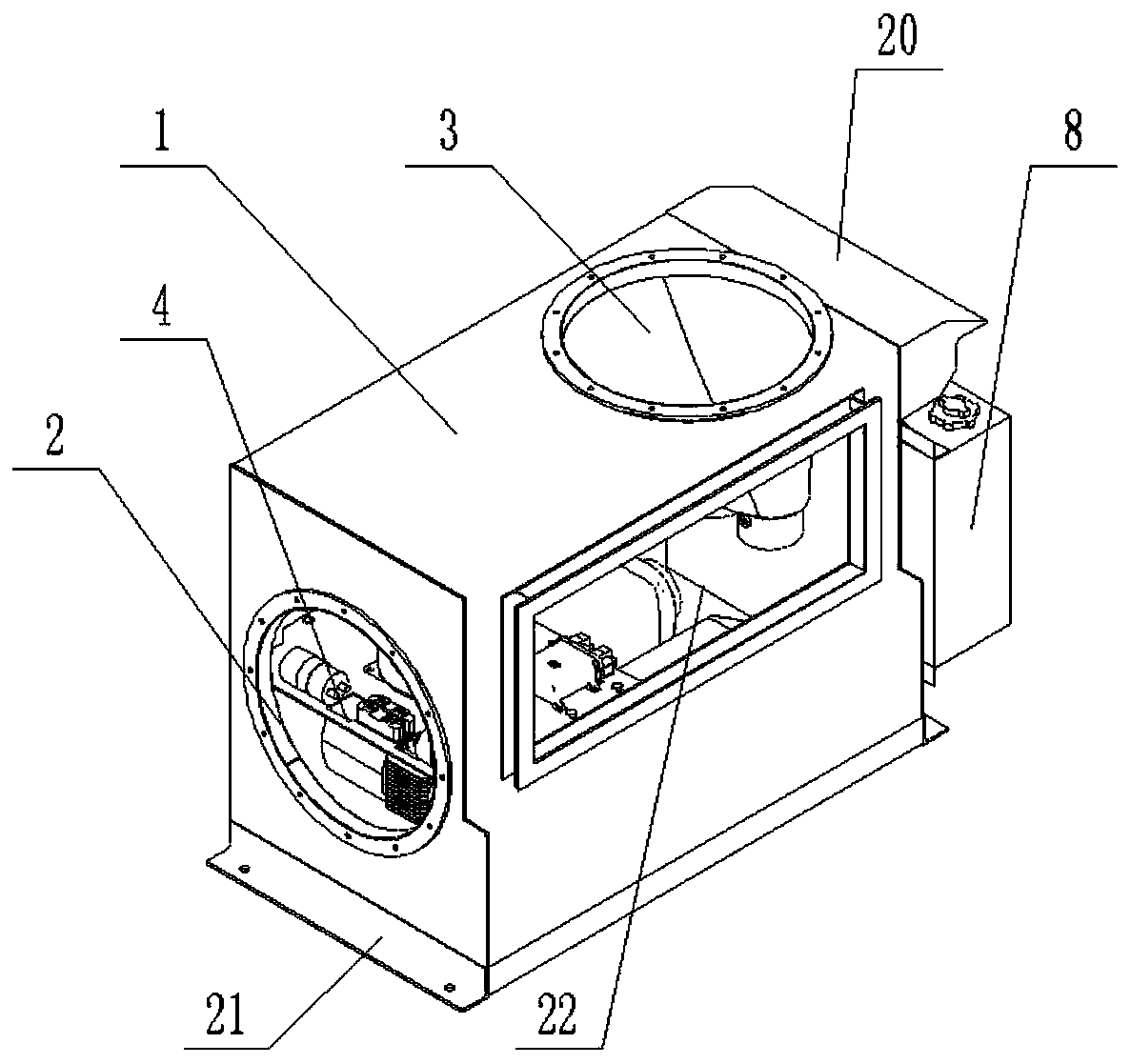

[0036] Such as Figure 1-11 As shown, an airtight fuel-air heater according to the embodiment of the present invention includes a sealed casing 1, a side of the casing 1 is provided with a cold air inlet 2, and a top surface of the casing 1 is provided with There is a hot air outlet 3, and the middle part of the chassis shell 1 is provided with an electrical component assembly, the electrical component assembly includes an electrical component mounting plate 4, and the electrical component mounting plate 4 is provided with a transformer 10, a controller 11, a rectifier bridge 12 and filter capacitor 13, the lower part of the chassis shell 1 is provided with a heater core assembly 5, one end of the heater core assembly 5 is connected with a fan 6, and the fan 6 is installed near the One end of the cold air inlet 2, the other end of the heater core assembly 5 is connected with the hot air outlet 3 through a pipeline 7, an oil tank assembly 8 is arranged outside the chassis shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com