Over-long threaded heat pipe of sucker rod

A sucker rod, heat pipe technology, applied in drill pipe, drill pipe, casing and other directions, to achieve the effect of convenient operation, increase heat transfer surface area, and prevent wax precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention will be further described below in conjunction with accompanying drawing:

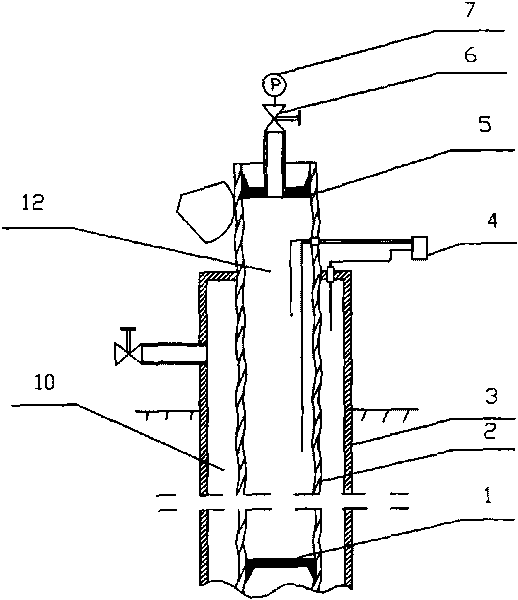

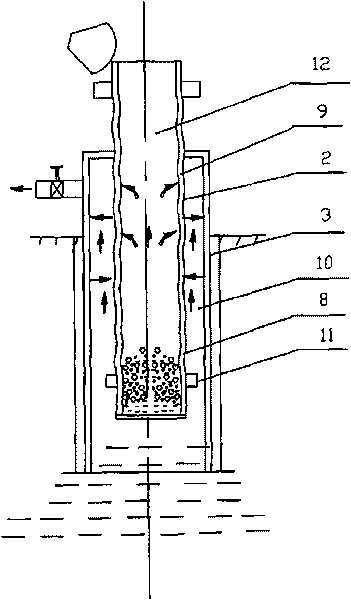

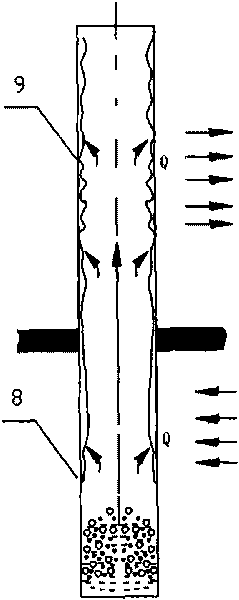

[0025] attached figure 1 to combine figure 2 As shown, the super-long sucker rod threaded heat pipe includes a sucker rod heat pipe 2 formed by sealingly connecting several sucker pipe sections. The inner cavity of the sucker rod heat pipe 2 forms a sealed cavity 12 filled with a working medium, and the sealed cavity The upper section of 12 is the heat pipe condensation section 9, the lower section of the sealed chamber 12 is the heat pipe evaporation section 8, the cavity body of the sealed chamber 12 is a threaded tubular shape, and the sealed chamber 12 is sealed by the upper plug cover 5 installed on the upper end of the sucker rod. The lower plug 1 at the bottom of the sucker rod and the sucker rod heat pipe 2 with the working medium between the upper and lower plugs are formed. The position of the lower plug 1 should be determined according to the temperature of the oil re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com